7 Best Serpentine Belt Tension Adjustment Techniques

When it comes to ensuring your vehicle's serpentine belt is in top condition, knowing the 7 best tension adjustment techniques is important. From using the belt tension gauge to checking for proper alignment, each method plays a key role in maintaining your car's performance.

But what if the tension isn't quite right? Stay tuned to discover the most effective technique to fine-tune the tension and keep your vehicle running smoothly.

Key Takeaways

- Proper tension inspection is vital for engine longevity and performance.

- Accurate measurement tools like tension gauges ensure optimal belt tension.

- Manual adjustment following manufacturer specifications prevents issues.

- Professional evaluation guarantees correct tension levels for peak functionality.

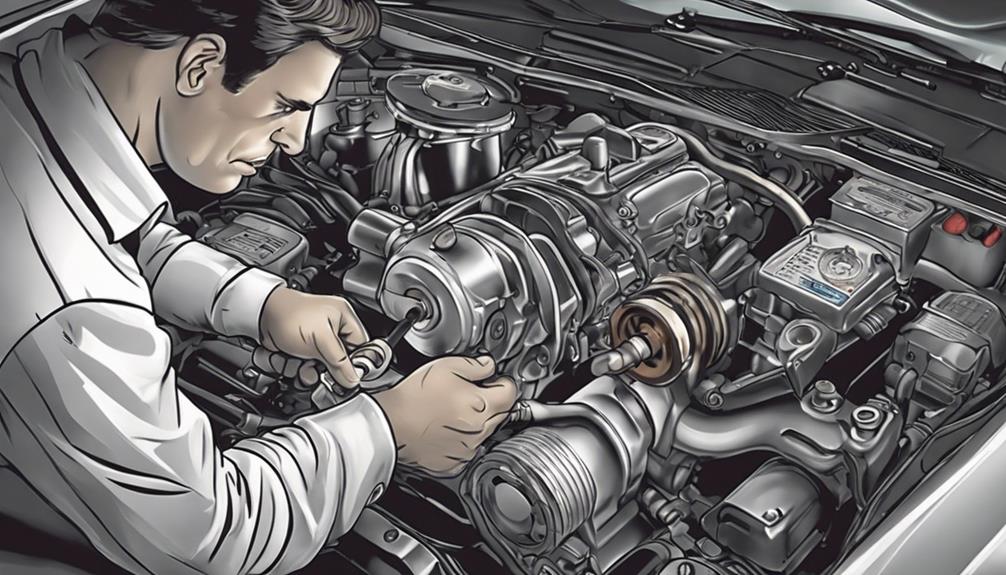

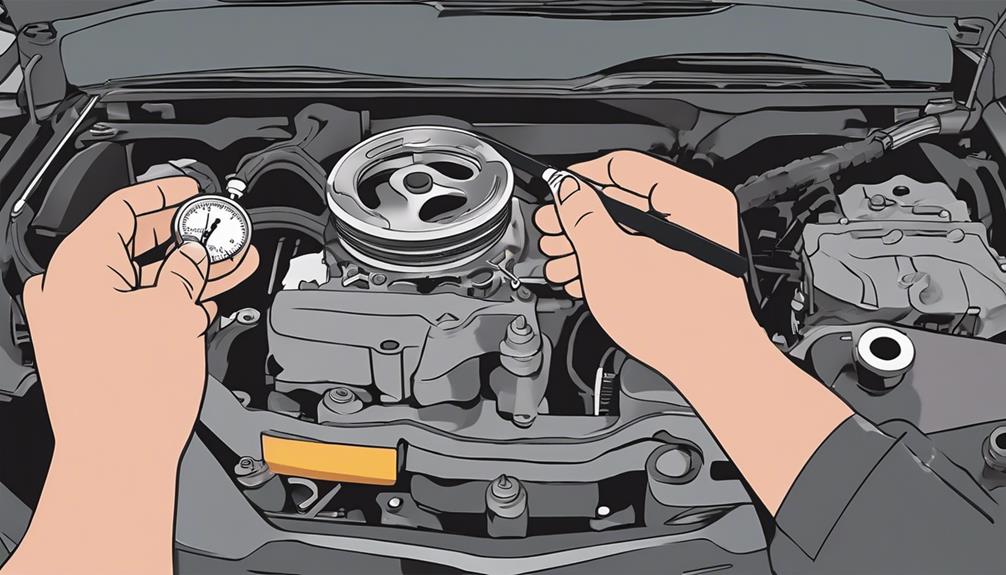

Proper Belt Tension Inspection

Have you ever wondered how to accurately assess the tension of your serpentine belt? Proper belt tension is essential for the best performance and longevity of your engine components. To measure the belt tension, you'll need a tension gauge calibrated to the specifications of your vehicle's manufacturer.

Belt tension measurement involves placing the tension gauge on the belt and applying a specific amount of force to determine the level of deflection. This deflection should fall within the recommended range provided by the manufacturer. If the tension is too loose, it can lead to slippage and premature wear of the belt and pulleys. Conversely, if the tension is too tight, it can put excessive stress on the components, leading to increased wear and potential belt failure.

Ensuring the correct tension of your serpentine belt through proper measurement not only enhances the efficiency of your engine but also reduces the risk of unexpected breakdowns. By regularly checking and adjusting the belt tension using a calibrated tension gauge, you can maintain the health and performance of your vehicle's engine system.

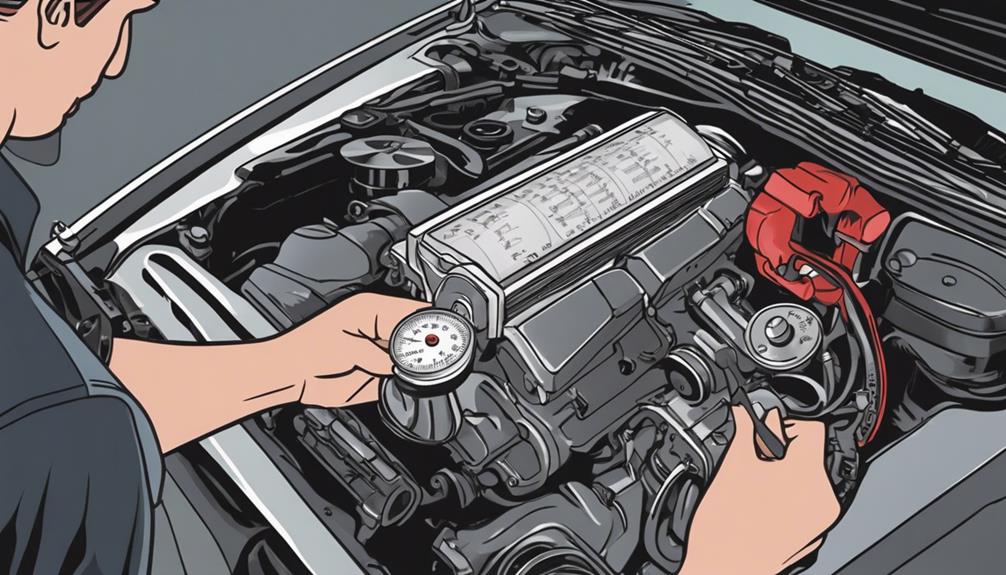

Using the Belt Tension Gauge

To effectively utilize the belt tension gauge, position the gauge on the serpentine belt and apply the specified force for accurate tension measurement. Belt tension measurement is a critical aspect of guaranteeing the proper functioning and longevity of your vehicle's serpentine belt system. When using a tension gauge, it's crucial to follow the manufacturer's guidelines to achieve accurate readings. Incorrect tension levels can lead to premature wear of the belt and its related components, causing costly repairs and potential breakdowns.

Tension gauge accuracy is paramount in maintaining the best performance of the serpentine belt. By using a reliable tension gauge, you can make sure that the belt is neither too loose nor too tight, preventing slippage or excessive stress on the system. Proper tension also aids in reducing noise and vibration, enhancing overall driving comfort.

Regularly monitoring and adjusting the belt tension using a tension gauge will help you proactively address any issues before they escalate, ultimately saving you time and money in the long run. Mastering the use of a tension gauge is a skill that every vehicle owner should possess to keep their serpentine belt system in top condition.

Adjusting Belt Tension Manually

For manual adjustment of belt tension, make sure you have the necessary tools and access to the tensioner pulley.

When adjusting belt tension manually, it's essential to follow a systematic approach to guarantee peak performance. Begin by identifying the tensioner pulley and using the appropriate tool to adjust the tension.

If the belt feels loose or makes squealing noises, it may indicate that the tension needs adjustment. To troubleshoot tension adjustment issues, carefully inspect the belt for signs of wear, such as cracks or fraying, which can affect tension.

DIY techniques for belt tension maintenance include checking the manufacturer's specifications for the correct tension levels and adjusting accordingly.

Common mistakes to avoid during manual tension adjustment include over-tightening the belt, which can strain the components, or under-tightening, leading to slippage.

Leveraging the Belt Tensioner Tool

Utilize the belt tensioner tool to precisely adjust the tension of the serpentine belt, guaranteeing peak performance and longevity of your vehicle's belt system. When using the tensioner tool, it's vital to start by confirming the tool is compatible with your specific vehicle model. Tensioner calibration is key to achieving the correct tension level. Begin by locating the belt tensioner pulley and attaching the tool securely to the tensioner arm. Slowly rotate the tensioner tool in the direction specified by the manufacturer to relieve tension on the belt.

Tool maintenance is essential for accurate adjustments. Before each use, inspect the tensioner tool for any signs of wear or damage. Keeping the tool clean and well-lubricated will help maintain its effectiveness. Regular calibration checks are recommended to guarantee the tool provides accurate tension adjustments.

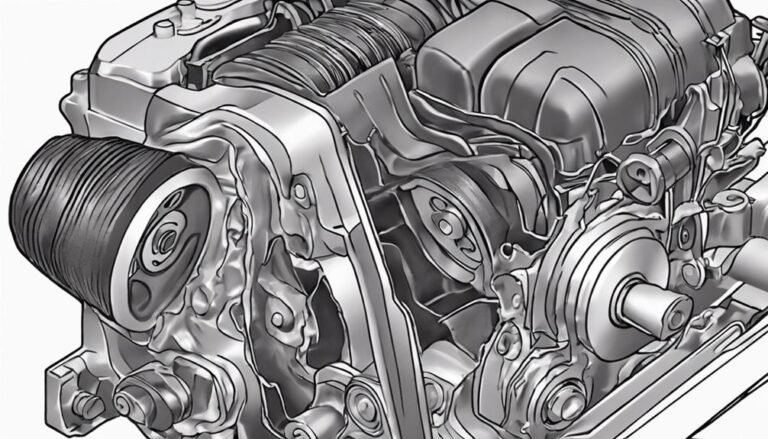

Checking for Proper Alignment

Inspect the alignment of the serpentine belt by visually checking its position relative to the pulleys for any deviations or misalignments. Important alignment is important for the efficient operation of the belt system. Misalignment can lead to premature wear and tear on the belt and pulleys, reducing the overall lifespan of the components.

To guarantee correct alignment, use a tension gauge for calibration. This tool helps in measuring the tension levels of the belt accurately. Adjust the tension if necessary to align the belt correctly with the pulleys.

Alignment inspection should be performed regularly as part of routine maintenance to avoid potential issues. When checking for alignment, pay close attention to any signs of the belt being off-center or not running in a straight line along the pulleys. Proper alignment ensures best performance and reduces the risk of belt slippage or damage.

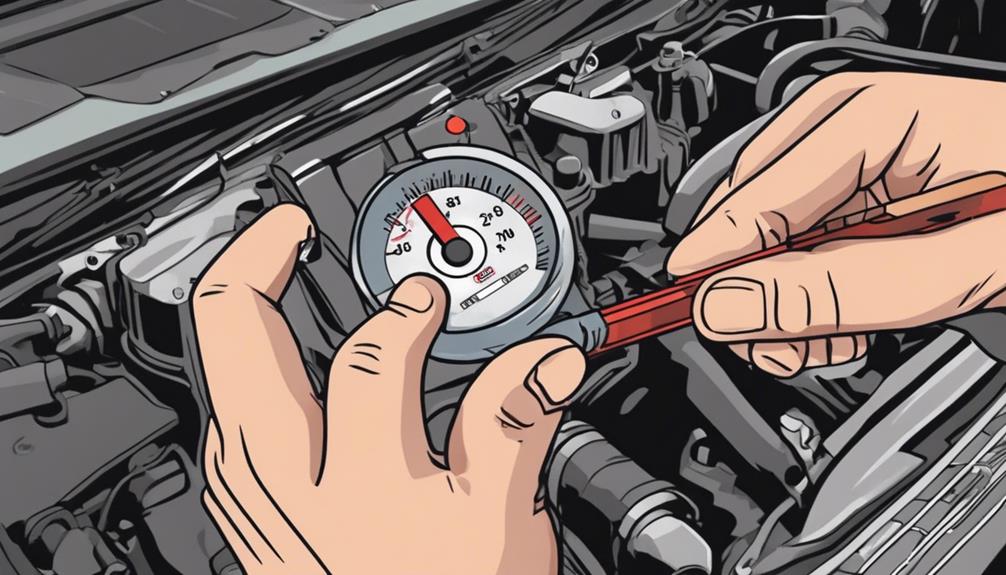

Utilizing the Belt Deflection Method

To confirm proper tension adjustment of the serpentine belt, consider employing the belt deflection method to accurately assess the belt's tension levels. When utilizing this method, pay attention to these key steps:

- Belt tension measurement: Begin by locating the longest belt span between pulleys. Apply pressure to the belt at the midpoint of this span with your thumb. Exert force equivalent to about 10 pounds and observe the belt's deflection. Ideal deflection ranges vary among vehicles, so refer to your manufacturer's specifications.

- Tension adjustment techniques: If the deflection is too much or too little, adjustments are necessary. Typically, an adjustment is made by altering the position of the tensioner pulley. Follow the manufacturer's guidelines on how to properly adjust the tension to ensure peak performance and longevity of the belt.

- Regular checks: Periodically re-evaluate the tension using the belt deflection method to maintain peak performance. Regular checks can help prevent premature wear and potential belt failure, ensuring your vehicle operates smoothly.

Verifying Tension With a Mechanic

To guarantee accuracy in tension assessment, depend on the expertise of a mechanic for a professional evaluation. Mechanics possess the knowledge and tools necessary to verify the correct tension levels with precision.

Mechanic's Expertise Verification

When confirming the tension of a serpentine belt, a mechanic's expertise is essential for accurate verification. To guarantee the mechanic's proficiency, you can follow these steps:

- Expertise Validation: Confirm that the mechanic has undergone proper certification requirements to work on automotive systems.

- Skill Assessment: Evaluate the mechanic's competency in belt tension adjustment techniques through practical tests or by checking their training background.

- Experience Review: Consider the mechanic's hands-on experience with serpentine belt tension adjustments, as practical familiarity plays a critical role in accurate verification.

Professional Tension Assessment

For a precise assessment of serpentine belt tension, collaborate closely with a seasoned mechanic to verify the tension accurately. Professional evaluation guarantees tension measurement accuracy, providing confidence in the belt's best performance.

A mechanic's expertise validation is essential in determining the correct tension level, which directly impacts the belt's functionality and longevity. Through professional assessment, the mechanic can confirm whether the tension meets the manufacturer's specifications, preventing issues like slippage or premature wear.

This methodical approach guarantees that the serpentine belt operates smoothly, transmitting power efficiently throughout the engine components. Trusting a mechanic for tension assessment not only enhances the belt's lifespan but also gives you peace of mind knowing that your vehicle is in top condition.

Frequently Asked Questions

Can I Use Any Type of Belt Tension Gauge for Adjusting Serpentine Belt Tension?

You can't use any belt tension gauge for adjusting serpentine belt tension. Always choose a gauge compatible with serpentine belts. Proper tension guarantees peak performance and longevity. Follow manufacturer guidelines for correct tension levels.

How Often Should I Check and Adjust the Tension of My Serpentine Belt?

Regularly check and adjust your serpentine belt tension to guarantee proper functioning of your vehicle. This maintenance task is essential for belt longevity and overall engine health. Neglecting it can lead to costly repairs.

Are There Any Specific Tools or Equipment Required for Adjusting Belt Tension Manually?

When manually adjusting belt tension, you'll need basic tools like a socket wrench and a tensioner tool. Benefits include precise adjustment control, but drawbacks include time consumption. Automatic methods simplify the process but may lack precision.

What Are Some Common Signs That Indicate a Serpentine Belt May Be Too Loose or Too Tight?

If your serpentine belt is too loose or tight, watch out for belt slipping and squealing. Make a visual inspection for misalignment or excessive wear. These signs indicate potential tension issues and may require adjustment.

Is It Necessary to Have a Professional Mechanic Verify the Tension of the Serpentine Belt, or Can It Be Done by a DIY Enthusiast?

You can check serpentine belt tension yourself, but for accuracy, professionals have specialized tools and experience. DIY methods involve manual inspection and general knowledge. Professional verification guarantees proper tension, preventing damage and ensuring peak performance.

Conclusion

In summary, ensuring proper serpentine belt tension is key for the best performance of your vehicle. Remember, 'A stitch in time saves nine' – take the time to inspect, adjust, and verify the tension using the techniques mentioned in this article.

By following these steps diligently, you can prevent costly repairs and breakdowns down the road. Keep your engine running smoothly by maintaining the right belt tension.