What to Consider for Serpentine Belt Compatibility?

When choosing a serpentine belt, compatibility is essential, like a puzzle piece needing to fit just right. Factors such as belt length, pulley size, tensioner compatibility, and manufacturer recommendations all play a role.

But what about material and design considerations? These often overlooked aspects can make or break the performance of your vehicle.

Stay tuned to discover why paying attention to these details can save you from future headaches and guarantee smooth operation of your engine.

Key Takeaways

- Verify tensioner compatibility to prevent premature wear and alignment issues.

- Choose belts made from durable materials like EPDM rubber for longevity.

- Ensure proper pulley alignment and material match for optimal performance.

- Adhere to manufacturer recommendations for peak serpentine belt compatibility.

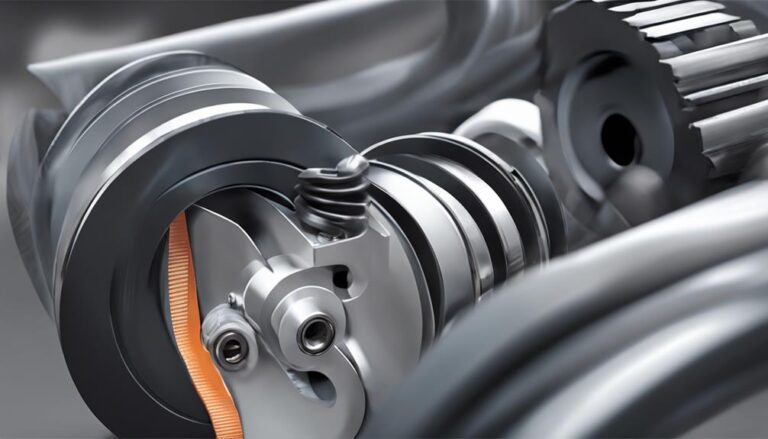

Serpentine Belt Length

When determining serpentine belt compatibility, measure the length of the belt accurately to guarantee proper fitment and peak performance. Belt tension is important for the serpentine belt to function at its best. Too much tension can lead to premature wear on the belt and other components, while too little tension can cause slippage and reduced efficiency. Ensuring the correct length of the belt helps maintain the ideal tension required for the system to operate smoothly.

Furthermore, considering the flexibility requirements of the serpentine belt is essential. The belt needs to have the right amount of flexibility to bend and adapt to the various pulleys within the system. If the belt is too rigid, it may not sit properly on the pulleys, leading to issues like noise and accelerated wear. On the other hand, if the belt is too flexible, it mightn't transfer power efficiently, impacting the overall performance of the vehicle. Selecting a serpentine belt with the appropriate flexibility is paramount for optimal functioning.

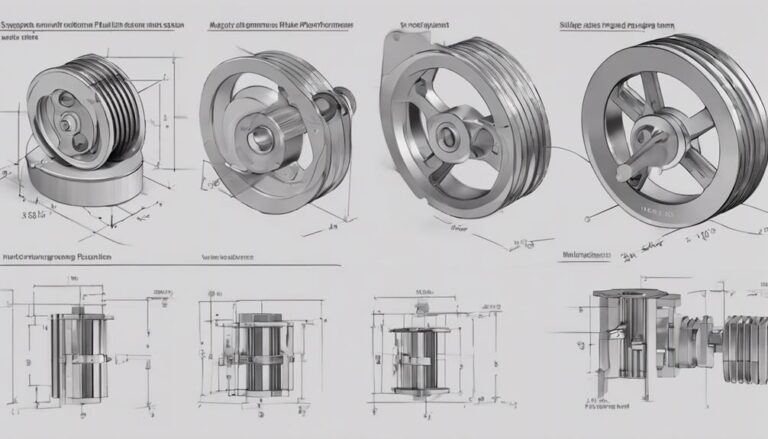

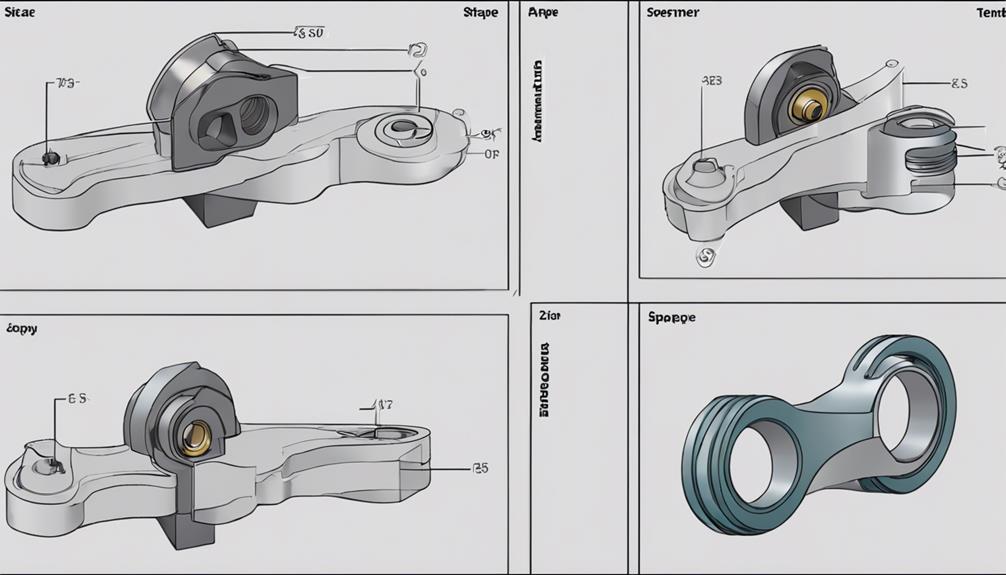

Pulley Size and Type

Considering the pulley size and type is important for ensuring proper serpentine belt compatibility and best system performance. To achieve this, pay attention to the following key factors:

- Pulley alignment: Guarantee that the pulleys are properly aligned to prevent premature wear and tear on the serpentine belt. Misaligned pulleys can lead to increased friction and reduced belt lifespan.

- Heat resistance: Opt for pulleys that offer high heat resistance to withstand the engine's temperature fluctuations. Heat-resistant pulleys are less likely to deform or crack under extreme conditions, ensuring longevity.

- Size compatibility: Choose pulleys that match the belt's width and material specifications. Incorrectly sized pulleys can cause slippage or excessive tension, leading to belt failure.

- Material durability: Select pulleys made from durable materials like steel or aluminum to withstand the rigors of daily use without succumbing to wear and tear easily.

- Type consideration: Different pulley types, such as idler pulleys or tensioner pulleys, serve unique functions in the serpentine belt system. Guarantee the chosen pulley type complements the overall system design for best performance.

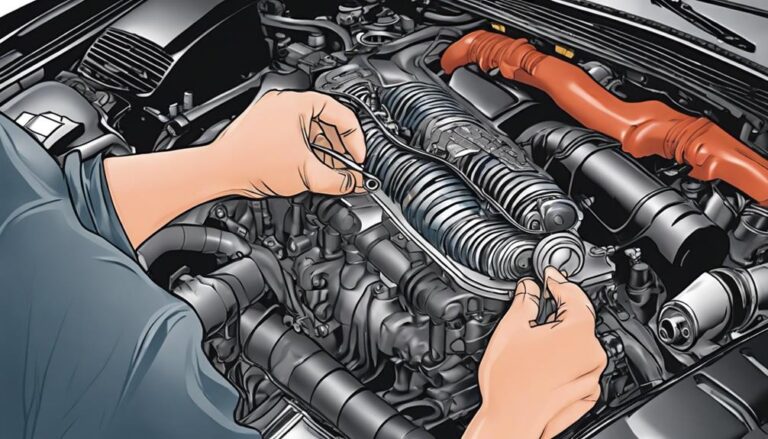

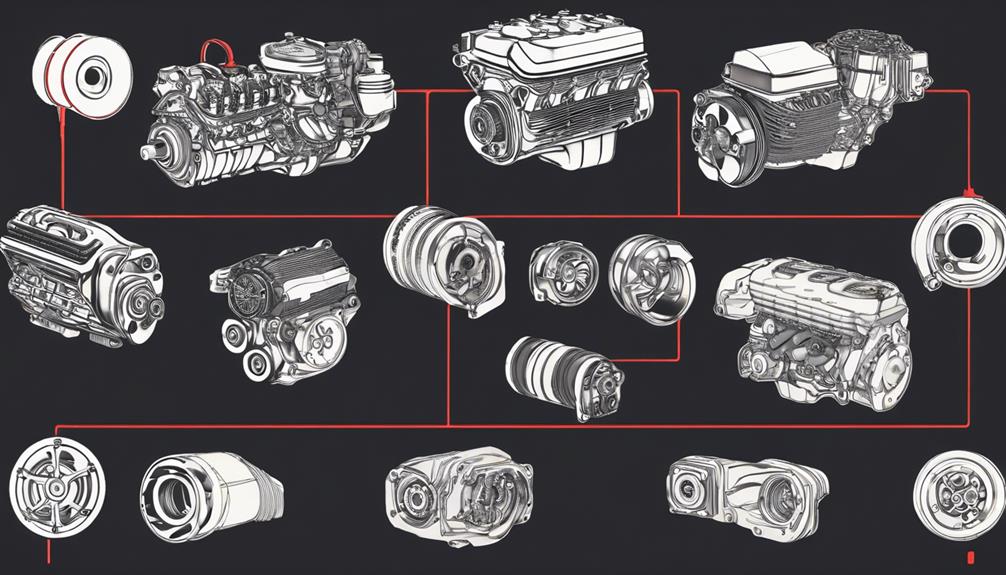

Tensioner Compatibility

Proper tensioner compatibility is essential for maintaining ideal serpentine belt performance and longevity. When considering tensioner compatibility, it's important to verify that the tensioner is designed to work seamlessly with the specific serpentine belt system. Incompatibility can lead to issues during the installation process, causing alignment problems that may result in premature belt wear and a higher replacement frequency.

During the installation process, a tensioner that isn't compatible can create alignment issues. This misalignment can cause the belt to wear unevenly, leading to decreased performance and potentially damaging other components in the system. Additionally, using a tensioner that isn't designed for your specific serpentine belt system can increase the frequency at which you need to replace the belt, adding unnecessary maintenance costs.

To avoid these problems, always confirm that the tensioner you choose is compatible with your serpentine belt system. This simple step can help you maintain ideal performance, reduce the frequency of belt replacements, and prolong the life of your entire belt system.

Material and Design Considerations

Confirm that the material and design of the serpentine belt are compatible with your vehicle's specifications to guarantee peak performance and longevity. When considering material and design for serpentine belts, focus on the following key aspects:

- Material Durability: Opt for belts made from high-quality materials like EPDM rubber for long-lasting performance.

- Design Flexibility: Look for belts with a design that allows for smooth operation around pulleys of various sizes.

- Performance Efficiency: Choose belts that offer low noise operation and reduced slippage for peak engine performance.

- Cost Effectiveness: Balance quality and cost by selecting belts that offer a good balance between performance and price.

- Maintenance Requirements: Consider belts that are easy to install and maintain to save time and effort in the long run.

Manufacturer Recommendations

To guarantee peak performance and longevity of your serpentine belt, it's essential to adhere to the manufacturer's recommendations regarding compatibility with your vehicle's specifications. Manufacturers provide specific guidelines on the type of serpentine belt that's best suited for your vehicle to ensure top performance. By following these recommendations, you can avoid issues such as premature wear, slippage, or improper fit that may arise from using an incompatible belt.

Installation tips provided by the manufacturer are vital to ensure the proper fitting of the serpentine belt. Proper installation not only guarantees top performance but also prevents potential damage to other engine components. Troubleshooting guidelines offered by the manufacturer can help address common issues that may arise during the installation or usage of the serpentine belt.

Regular maintenance, as recommended by the manufacturer, is essential for the durability of the serpentine belt. Following the maintenance schedule provided ensures that the belt functions properly and lasts longer, reducing the need for frequent replacements. By adhering to the manufacturer's recommendations for installation, troubleshooting, maintenance, and durability, you can maximize the performance and lifespan of your serpentine belt.

Frequently Asked Questions

Can a Serpentine Belt Be Used on Multiple Vehicles With Different Engine Sizes?

When considering serpentine belt compatibility across vehicles with different engine sizes, it's important to match the belt's length, width, and number of ribs to the specific engine requirements. Guarantee proper tension and alignment for the best performance and longevity.

What Are the Potential Consequences of Using a Serpentine Belt That Is Too Long or Too Short for a Specific Vehicle?

Using a serpentine belt that is too long or too short for your vehicle can lead to issues like poor performance, belt slippage, or increased wear. Incorrect belt length affects tension, impacting overall function.

Are There Any Aftermarket Tensioner Options Available for Vehicles That May Not Have Compatible Tensioners With Standard Serpentine Belts?

When looking for aftermarket options, consider aftermarket tensioners for various engine sizes. They can provide compatibility solutions for vehicles lacking standard tensioners. It's essential to confirm proper fit and quality to avoid belt issues.

How Do Material and Design Considerations Affect the Overall Performance and Longevity of a Serpentine Belt?

Consider material compatibility and design performance vital for serpentine belt longevity. Material quality affects durability, while design impacts how efficiently power transfers. Opt for belts that match your vehicle's specifications to guarantee top performance and longevity.

Are There Any Special Installation Procedures or Tips for Serpentine Belts That Differ From Traditional V-Belts?

To install a serpentine belt properly, you must use special tools for tensioning. Assure correct tensioning to prevent slipping or premature wear. Follow specific routing diagrams for your vehicle to avoid installation errors.

Conclusion

In summary, when considering serpentine belt compatibility, it's important to make sure the length, pulley size, tensioner compatibility, and material/design align with your vehicle's specifications.

Just as a well-oiled machine operates smoothly with the right parts, a perfectly compatible serpentine belt ensures peak performance and longevity for your engine.

Remember, precision and attention to detail are key in selecting the right serpentine belt for your vehicle.