5 Signs Your Pulley Needs Replacement

Imagine driving down the highway, the engine purring smoothly until you hear a sudden screeching noise emanating from under the hood. Your heart skips a beat as you wonder what could be causing it.

Well, that unsettling sound might just be your pulley signaling for help. But don't worry, you're in safe hands with the top 5 signs that indicate your pulley could be on the verge of giving up.

Stay tuned to learn how to spot these warning signals before they escalate into a major issue.

Key Takeaways

- Unusual noises like squealing or grinding indicate pulley issues.

- Visual signs include fraying belts, cracks, rust, and grooves.

- Vibrations and belt misalignment point to potential pulley problems.

- Regular maintenance, lubrication, and alignment prevent costly replacements.

Unusual Noises

If you hear a high-pitched squealing or grinding sound coming from your pulley, it may indicate the need for replacement. These noises are often caused by worn-out bearings within the pulley system. To prevent further damage and guarantee the smooth operation of your pulley, it's important to address these warning signs promptly.

Maintenance tips for addressing unusual noises in your pulley system include regular inspection of the pulley for any signs of wear or damage. Lubricating the bearings can also help reduce friction and noise in the system. Additionally, making sure that the pulley is properly aligned and tensioned can prevent unnecessary strain on the bearings, prolonging their lifespan.

Common causes of unusual noises in pulleys include worn-out bearings, misalignment, improper tension, or foreign objects lodged in the pulley system. By addressing these issues promptly and following proper maintenance tips, you can ensure the best performance of your pulley system and avoid costly repairs in the future.

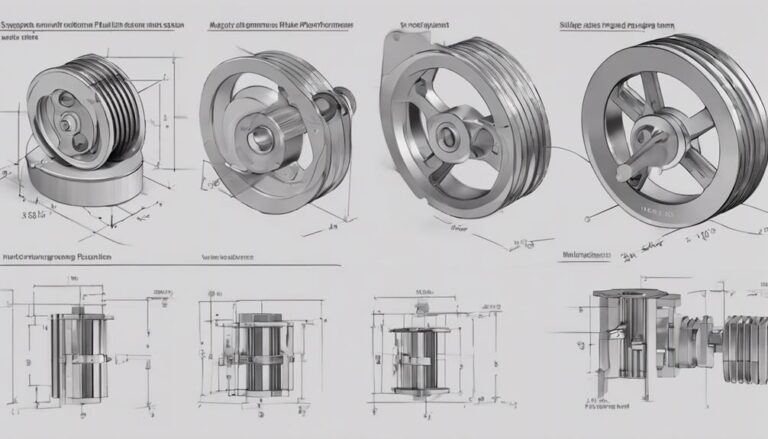

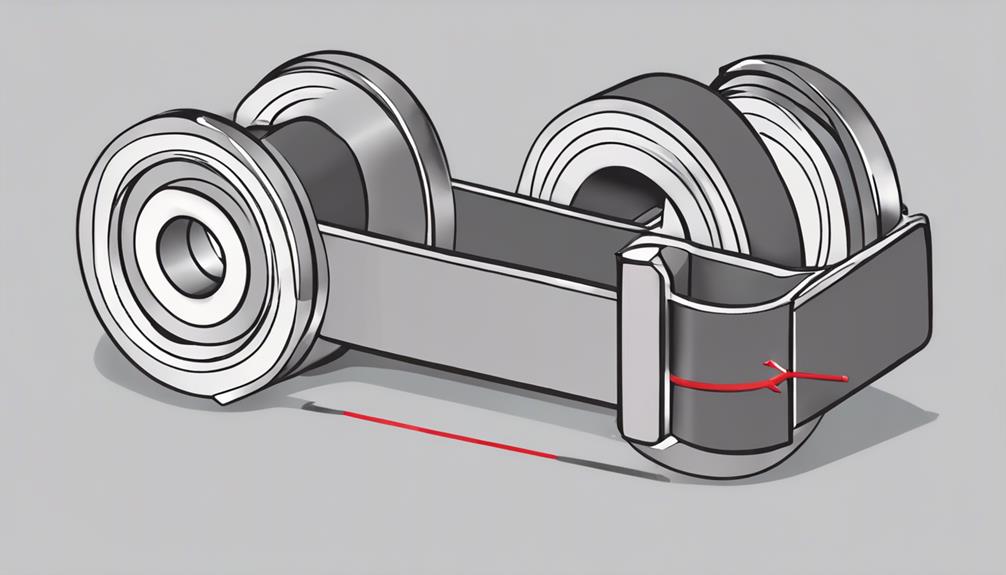

Visible Wear

Visible wear on a pulley can be identified through physical signs such as fraying belts, cracks on the pulley surface, or grooves worn into the pulley walls. When inspecting your pulley, pay close attention to any rust accumulation or surface cracks, as these are indicative of wear and potential issues.

Here are some key indicators to look for:

- Fraying Belts: Check for any fraying or visible damage on the belts connected to the pulley.

- Surface Cracks: Examine the pulley surface for any cracks, which can weaken the structure.

- Rust Accumulation: Rust can accelerate wear and compromise the integrity of the pulley.

- Grooves on Walls: Inspect the walls of the pulley for grooves, as these can affect the alignment and performance of the system.

Regularly monitoring these visible wear signs can help you catch pulley issues early and prevent further damage to your equipment.

Squeaking Sounds

Listen closely for squeaking sounds emanating from your pulley system as they may indicate potential issues requiring immediate attention. Squeaking noises are often a sign of inadequate lubrication maintenance on the pulley components. Due to friction between moving parts, lack of proper lubrication can lead to increased wear and tear, causing the pulley system to operate less efficiently and possibly resulting in further damage.

To address squeaking sounds, start by checking the level and quality of lubrication on the pulley system. Confirm all moving parts are adequately lubricated to reduce friction and minimize noise. Regular lubrication maintenance is essential for the smooth operation of the pulley system and can prevent premature wear on the components.

If lubrication isn't the issue, consider adjusting the tension of the pulley system. Incorrect tension can also lead to squeaking sounds as the belt or chain slips on the pulley surfaces. Proper tension adjustment is vital for optimizing the performance and longevity of the pulley system.

Vibrations

Check for any abnormal vibrations in your pulley system, as they could indicate underlying issues that require attention. When you notice unusual vibrations, it's essential to address them promptly to prevent further damage to your pulley system.

Here are some key points to take into account:

- Balancing Issues: Imbalanced pulleys can cause vibrations that may lead to premature wear and tear on the system components. Regular maintenance checks can help identify and correct any balancing issues before they escalate.

- Motor Vibrations: Excessive vibrations in the pulley system may be linked to motor vibrations. Troubleshooting the motor to make sure it's functioning correctly can help resolve this issue effectively.

- Maintenance: Proper maintenance of the pulley system, including lubrication of moving parts and regular inspections, can help reduce vibrations and extend the lifespan of your pulleys.

- Troubleshooting: If vibrations persist despite maintenance efforts, thorough troubleshooting of the entire system is necessary to pinpoint the root cause and implement the appropriate solution.

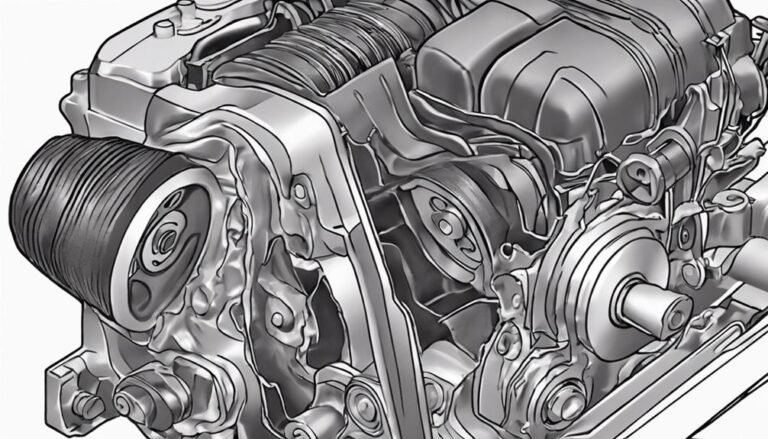

Belt Misalignment

To identify belt misalignment in your pulley system, conduct a visual inspection and check for any deviation from the proper alignment of the belt with the pulleys. Misalignment can lead to various issues such as increased wear on the belt and pulleys, reduced efficiency, and potential damage to the entire system. Here's a table outlining the common signs, causes, and solutions related to belt misalignment:

| Signs | Causes | Solutions |

|---|---|---|

| Excessive noise | Misaligned pulleys | Realign the pulleys |

| Uneven belt wear | Improper installation | Adjust belt tension |

| Reduced performance | Worn-out pulley bearings | Replace worn-out bearings |

| Overheating | Belt tension too high or too low | Adjust belt tension to manufacturer's specs |

| Premature failure | Lack of maintenance | Regularly inspect and maintain the system |

Regular maintenance and proper alignment are important for ensuring the best performance and longevity of your pulley system. By addressing alignment issues promptly and maintaining appropriate belt tension, you can enhance the efficiency and reliability of your machinery.

Frequently Asked Questions

Can a Worn Pulley Cause Damage to Other Parts of the Engine System?

A worn pulley can indeed cause damage to other parts of the engine system. It can lead to issues with belt tension and alignment, affecting engine performance and requiring immediate maintenance to prevent further complications.

How Often Should Pulleys Be Inspected for Wear and Tear?

For best engine performance, adhere to your maintenance schedule. Regularly inspect pulleys for wear and tear. Signs like squeaking or wobbling indicate deterioration. Follow guidelines for inspection frequency to prevent damage and guarantee smooth operation.

Can a Pulley Be Repaired or Does It Need to Be Completely Replaced?

Repairing a pulley can be cost-effective, depending on its condition. Factors like material quality and maintenance affect lifespan. Regular inspections help determine if repair is viable. Consult a professional for guidance on repair vs. replacement.

Are There Any Warning Signs That Indicate a Pulley Is About to Fail?

To guarantee peak performance, pulley maintenance is essential. Implement preventive measures to prolong its lifespan. Early detection of issues can provide various replacement options, safeguarding your system's functionality and preventing unexpected failures in the future.

What Are the Potential Consequences of Ignoring a Pulley That Needs Replacement?

Ignoring a pulley that needs replacement can lead to serious consequences, such as belt slippage, overheating, and engine damage. Regular maintenance tips include checking for wear and tear and addressing issues promptly. Common misconceptions may underestimate pulley importance.

Conclusion

To sum up, if you notice any of these signs – unusual noises, visible wear, squeaking sounds, vibrations, or belt misalignment – it's time to replace your pulley. Don't wait until it completely fails and causes further damage to your system.

Just like a well-oiled machine, your pulley plays an essential role in ensuring smooth operation. Addressing these warning signs promptly will help you avoid costly repairs down the line.

Keep your system running smoothly by replacing your pulley when necessary.