Ultimate Guide to Serpentine Belt and Pulley Repairs

When it comes to keeping your car running smoothly, the serpentine belt and pulleys are like the orchestra conductor, ensuring all components work in harmony.

But what happens when this essential ensemble starts to falter? Understanding the signs of wear and misalignment can save you from a breakdown on the road.

Stay tuned to uncover the essential steps to diagnose and repair these essential components, ensuring your vehicle's performance remains at its peak.

Key Takeaways

- Proper pulley lubrication prevents common noises and ensures efficient power transfer.

- Inspect serpentine belt for wear regularly to avoid issues like cracks or slippage.

- Address misalignment promptly to prevent premature wear and noise in the system.

- Replace faulty pulleys correctly by selecting the right part and adjusting belt tension post-repair.

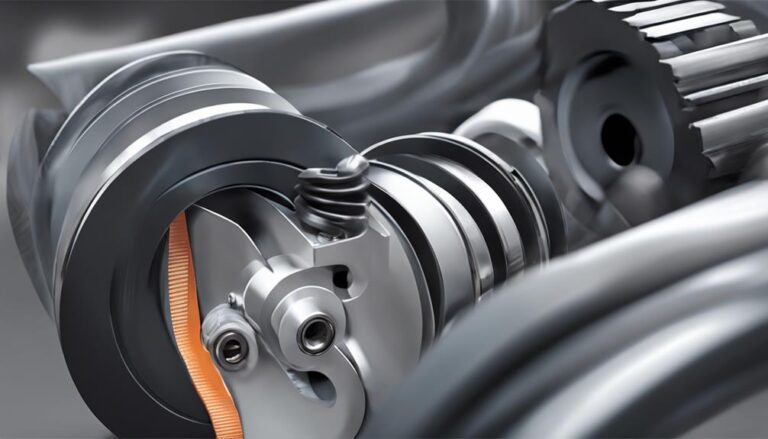

Common Pulley Noise Symptoms

Hearing a squealing or grinding noise coming from your vehicle's engine area could indicate potential issues with the pulleys. Proper pulley lubrication methods are essential to prevent such noises. The pulleys in your vehicle play a vital role in the serpentine belt system, ensuring that power is efficiently transferred to various components like the alternator, water pump, and air conditioning compressor.

To address pulley noise, start by checking the belt tension adjustment techniques. A loose belt can cause the pulleys to slip, leading to unwanted sounds. Adjust the tension according to your vehicle manufacturer's specifications. Additionally, consider applying lubrication to the pulleys to reduce friction and noise. This can involve using a specific lubricant recommended for your vehicle's pulleys.

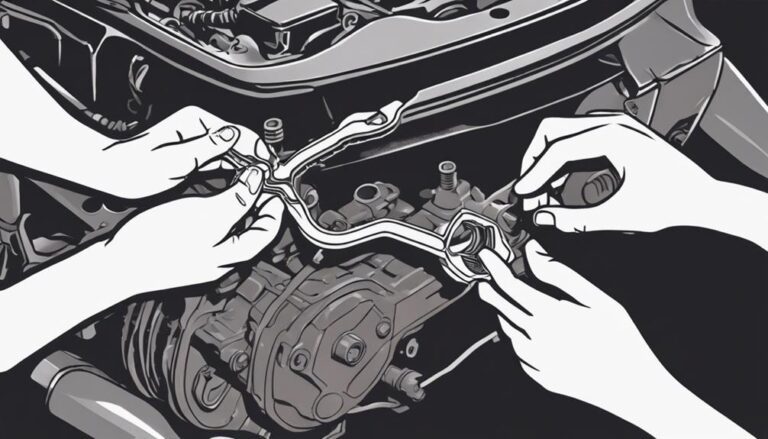

Inspecting Serpentine Belt for Wear

Inspect the serpentine belt for wear by visually examining its surface for cracks, fraying, or signs of excessive wear. Begin by checking belt tension, ensuring it's neither too loose nor too tight.

Look for any visible damage such as missing ribs, chunks of rubber, or uneven wear patterns along the belt. These signs can indicate that the belt is reaching the end of its lifespan and may need replacement soon.

Pay close attention to any shiny or glazed areas on the belt, which can suggest slippage or overheating. Additionally, inspect the belt for any oil contamination, as this can lead to accelerated wear and reduced grip on the pulleys.

If you notice any of these signs of wear, it's recommended to replace the serpentine belt promptly to prevent potential breakdowns or damage to other engine components. Regularly inspecting the belt for signs of wear is important in maintaining the overall health and performance of your vehicle's engine system.

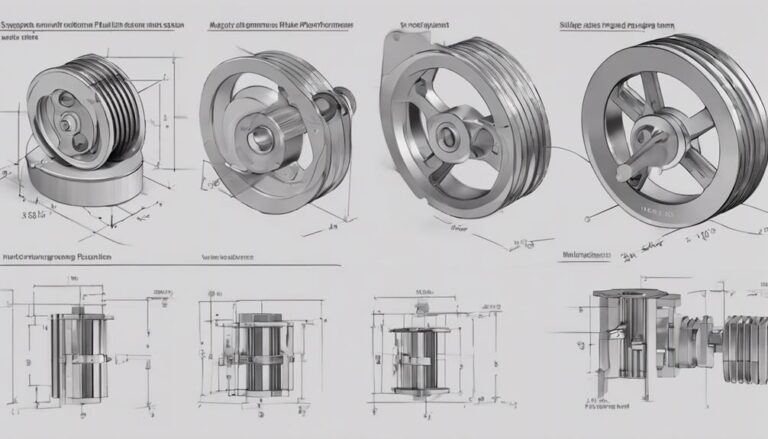

Identifying Pulley Misalignment Issues

To identify pulley misalignment issues, carefully observe the alignment of the pulleys in relation to each other and their corresponding components. Proper pulley alignment is essential for the serpentine belt system to function at its best. When pulleys are misaligned, it can lead to premature wear of the belt, noise, and other issues. Here are some pulley alignment techniques and troubleshooting misalignment causes:

| Pulley Alignment Techniques | Troubleshooting Misalignment Causes | Additional Notes |

|---|---|---|

| Use a straight edge to check alignment visually | Check for loose mounting bolts or brackets | Proper alignment guarantees even distribution of tension |

| Measure the distance between pulleys on the same plane | Inspect for bent or damaged pulleys | Misalignment can cause the belt to slip or wear unevenly |

| Check for parallel alignment of pulley grooves | Ensure the pulleys are properly seated on their shafts | Misaligned pulleys can lead to increased friction and decreased efficiency |

| Utilize a laser alignment tool for precision | Verify that the belt is running true on all pulleys | Seek professional help if alignment issues persist |

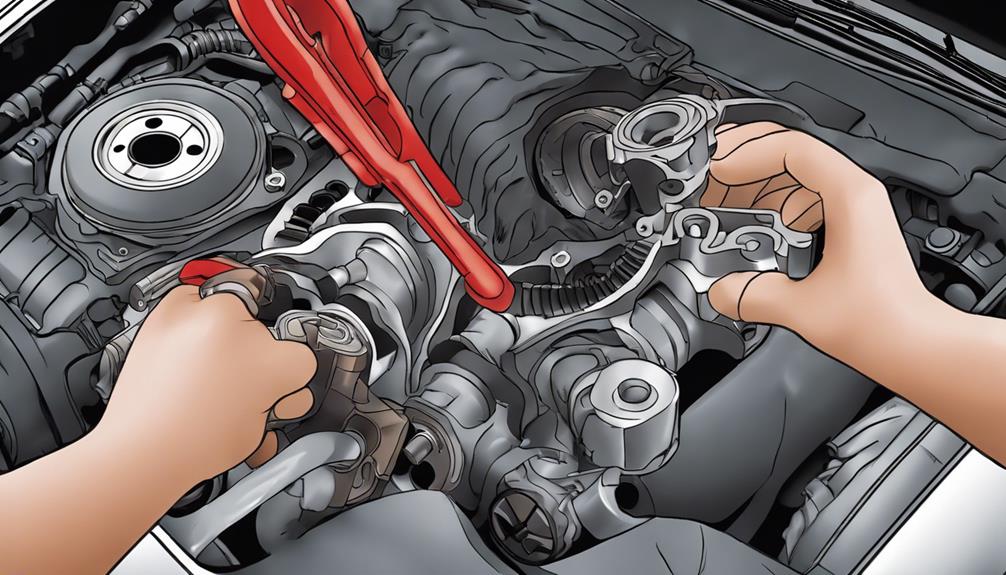

Steps to Replace Faulty Pulleys

When replacing faulty pulleys, commence by carefully selecting the correct replacement part based on the specific pulley type and size observed during the alignment check.

To commence the replacement process, confirm the engine is cool and disconnect the battery to prevent any accidents. Use the appropriate tools to loosen the tensioner and remove the serpentine belt.

Next, identify the faulty pulley by checking for any wobbling or noise when spinning. Once the damaged pulley is located, carefully remove it by unbolting it from the engine block. Clean the mounting surface thoroughly to guarantee proper seating of the new pulley.

Install the new pulley by bolting it securely into place. After the new pulley is installed, reattach the serpentine belt following the correct routing diagram.

Testing Belt Tension After Repair

After completing the pulley replacement process, confirm the serpentine belt tension is correctly adjusted to prevent slippage or damage. To guarantee peak performance, follow these essential steps:

- Measuring Tension: Use a tension gauge to measure the belt's tightness accurately.

- Proper Tools: Make sure you have the correct tools, such as a tension gauge and a wrench, for accurate adjustments.

- Troubleshooting Techniques: Check for any signs of misalignment or unusual noises that may indicate incorrect tension.

- Belt Alignment: Verify that the belt is aligned correctly on all pulleys to prevent premature wear.

Frequently Asked Questions

Can Using a Specific Type of Serpentine Belt Affect the Longevity of the Pulleys?

Using a specific type of serpentine belt can indeed impact the longevity of the pulleys. Belt material and maintenance practices play important roles in this. Proper belt selection and regular maintenance can help extend the life of your pulleys.

Are There Any DIY Methods for Preventing Pulley Issues in the Future?

To prevent future pulley issues, engage in DIY preventative maintenance. Regularly inspect pulleys for wear, cracks, or misalignment. Clean debris and confirm proper tension on the serpentine belt. These simple maintenance tips can troubleshoot and extend pulley longevity.

How Often Should Serpentine Belts and Pulleys Be Inspected and Replaced?

When it comes to your vehicle's serpentine belts and pulleys, it's essential to inspect them regularly for signs of wear or damage. Typically, these components should be checked every 60,000 miles and replaced if necessary.

Can Extreme Weather Conditions Impact the Performance of Serpentine Belts and Pulleys?

In extreme weather, belt tension and maintenance are important. Corrosion from moisture and heat impacts can weaken belts and pulleys. Regular checks and replacements guarantee top performance, preventing breakdowns and costly repairs.

Are There Any Specific Tools or Equipment Needed for Pulley Repairs That Aren't Mentioned in the Article Sections?

When tackling pulley repairs, specialized tools like pulley pullers or holding tools are essential. These equipment pieces aid in efficient maintenance and prevent damage. DIY methods can be effective, but having the right gear guarantees precision.

Conclusion

Now that you have mastered the art of serpentine belt and pulley repairs, you're equipped to keep your vehicle running smoothly and efficiently. Just like the gears in a well-oiled machine, each component plays a vital role in the overall performance.

Remember, proper maintenance is the key to ensuring a long-lasting and reliable drive. Stay vigilant and attentive to the signs, and your vehicle will reward you with a seamless journey ahead.