What Makes Quality Belt and Pulley Materials Essential?

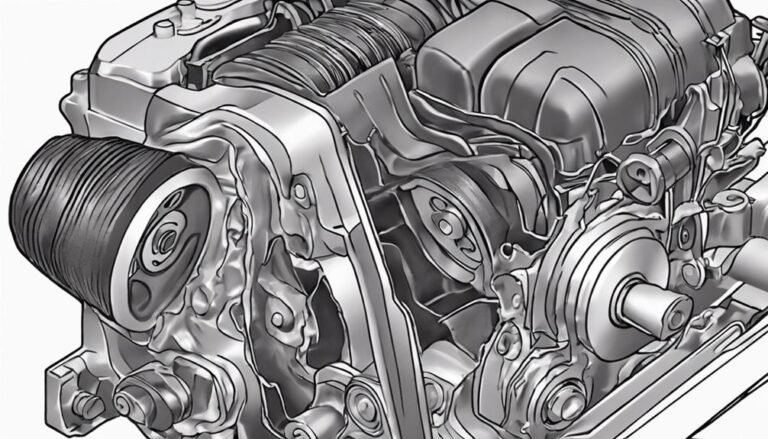

Imagine a smoothly running machine, each component working in perfect harmony. Now, consider the pivotal role that belt and pulley materials play in maintaining this precision.

The quality of materials used in these components can ultimately determine the efficiency, reliability, and longevity of your machinery. Understanding why selecting top-tier materials is vital will not only optimize performance but also prevent costly breakdowns and downtime.

Let's uncover the critical aspects that make quality belt and pulley materials an indispensable choice for any mechanical system.

Key Takeaways

- Quality materials ensure durability, efficiency, and longevity in mechanical systems.

- Material properties like tensile strength, hardness, and friction directly impact performance.

- Premium materials offer enhanced longevity, reduced maintenance, and consistent performance.

- Investing in high-grade materials leads to significant cost savings and reliability over time.

Importance of Quality Materials in Belts

Ensuring that belts are made from high-quality materials is essential for maintaining excellent performance and durability in various mechanical systems. The durability of a belt is vital for the efficiency of the entire system. When belts are crafted from superior materials, they can withstand the demanding conditions of continuous operation without succumbing to wear and tear easily.

High-quality belt materials contribute greatly to the efficiency of mechanical systems. Durability ensures that the belt can transmit power effectively without stretching or breaking prematurely. This reliability leads to smoother operation, minimizing downtime and maintenance costs. Choosing the right materials for belts can enhance the overall performance of the system, providing a sense of security and belonging among users who rely on consistent and efficient operation.

Significance of Pulley Material Durability

The durability of pulley materials plays an important role in maintaining the efficiency and reliability of mechanical systems. When selecting pulley materials for your machinery, consider the following:

- Enhanced Longevity: Durable pulley materials offer longevity, reducing the frequency of replacements and maintenance tasks. This benefit translates to cost savings and increased operational efficiency over time.

- Consistent Performance: Materials with high durability guarantee consistent performance even under demanding conditions. This reliability is vital for the smooth operation of your mechanical systems.

- Reduced Downtime: Pulleys made from durable materials are less likely to fail prematurely, leading to reduced downtime for repairs. This results in improved productivity and minimized disruptions in your operations.

- Long-Term Savings: While durable pulley materials may have a higher upfront cost, their long-lasting performance ultimately leads to significant savings by avoiding frequent replacements and associated labor costs.

Choosing pulley materials known for their durability benefits ensures long-lasting performance, contributing to the overall effectiveness and longevity of your mechanical systems.

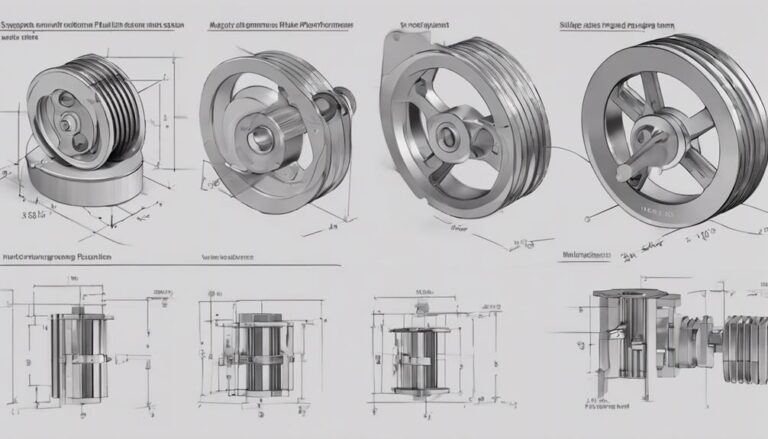

Impact of Material Selection on Performance

Selecting the right materials influences the performance of pulleys in mechanical systems. Material properties play a critical role in determining how effectively a pulley can transmit power and motion. The choice of material impacts key performance factors such as load-bearing capacity, wear resistance, and overall longevity. For instance, materials with high tensile strength are essential for handling heavy loads without deformation. Hardness is another essential property that affects the pulley's resistance to wear and abrasion over time. Additionally, the coefficient of friction between the belt and pulley material can have a substantial impact on the efficiency of power transmission.

Furthermore, the thermal conductivity of the material can influence how effectively the pulley dissipates heat generated during operation, preventing overheating and potential damage. By carefully considering these material properties, you can optimize the performance of pulleys within your mechanical systems, ensuring smooth operation and minimal downtime. Ultimately, the right material selection is paramount in achieving the best performance and reliability in belt and pulley systems.

Why Material Quality Is Non-Negotiable

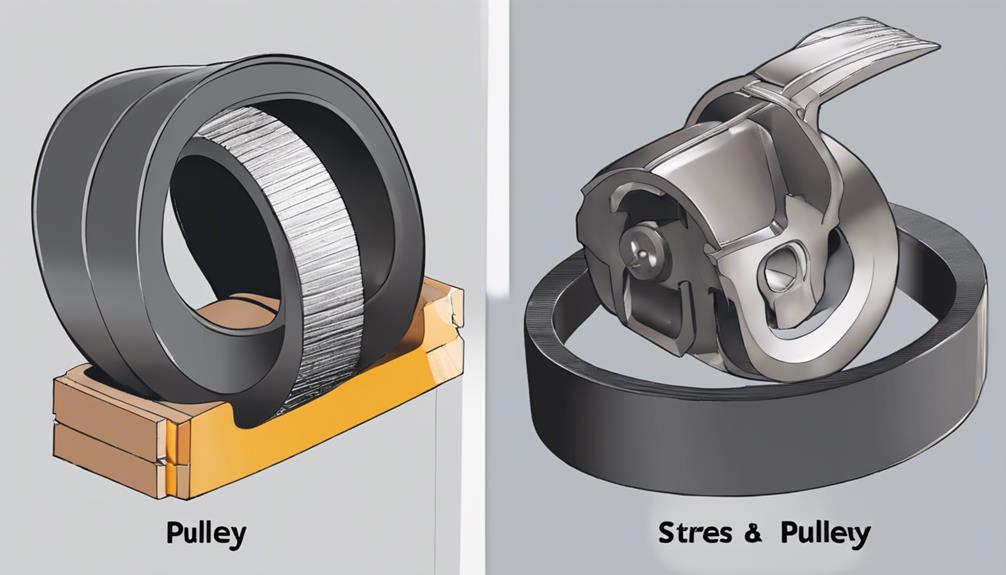

Material quality stands as a non-negotiable factor in the peak performance and longevity of pulleys within mechanical systems. When it comes to ensuring the durability standards and best functionality of your pulleys, the material composition plays a pivotal role. Here's why material quality is important:

- Wear Resistance: High-quality materials are essential to resist wear and tear, ensuring that your pulleys can withstand the demands of continuous operation without deteriorating quickly.

- Strength and Load-Bearing Capacity: Premium materials offer superior strength and load-bearing capacity, allowing the pulleys to handle heavy loads efficiently without compromising performance.

- Corrosion Resistance: Quality materials are often corrosion-resistant, protecting the pulleys from environmental factors that could lead to rust or degradation over time.

- Consistent Performance: The material composition directly impacts the overall performance consistency of the pulleys, ensuring smooth operation and minimal downtime in your mechanical systems.

Ensuring Longevity With Premium Materials

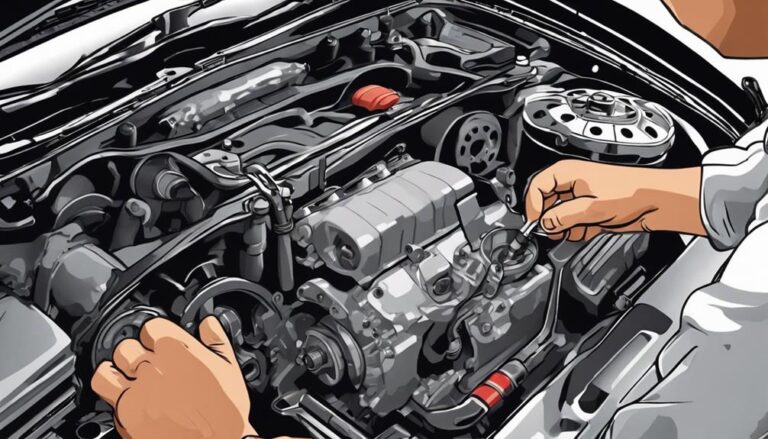

To guarantee longevity with premium materials, prioritizing wear resistance is paramount in maintaining the best functionality of pulleys in mechanical systems. Premium materials offer significant longevity benefits due to their superior durability and resistance to wear over time. When selecting materials for pulleys, it's essential to take into account the specific requirements of the application to guarantee performance and extended lifespan.

Premium materials such as high-grade metals or advanced polymers exhibit exceptional wear resistance properties, reducing the need for frequent replacements and minimizing downtime in industrial operations. By choosing materials known for their longevity benefits, you can enhance the reliability and efficiency of your mechanical systems while reducing maintenance costs in the long run.

Investing in premium materials may initially require a higher upfront cost, but the extended lifespan and durability they provide ultimately result in significant cost savings over time. By prioritizing the use of premium materials with superior wear resistance, you can ensure the longevity and best performance of your pulleys, contributing to the overall efficiency and reliability of your mechanical systems.

Frequently Asked Questions

How Do Belt and Pulley Materials Affect the Overall Efficiency of a System?

When choosing belt and pulley materials, consider their impact on efficiency. Quality materials enhance system performance, ensuring longevity and durability. Opt for superior materials to optimize efficiency and maintain peak system performance over time.

Can Using Lower Quality Materials in Belts and Pulleys Lead to Safety Hazards?

Using lower quality materials in belts and pulleys can pose significant safety risks and lead to performance issues. Your system's efficiency may suffer, and you could encounter unexpected failures, jeopardizing both equipment and personnel safety.

What Factors Should Be Considered When Selecting the Right Materials for Belts and Pulleys?

When choosing materials for belts and pulleys, make sure they offer top strength and durability for the intended application. Consider compatibility and performance requirements to achieve efficient operation. Selecting quality materials is essential for long-term reliability.

Are There Any Environmental Concerns Associated With the Manufacturing of Belt and Pulley Materials?

When considering belt and pulley materials, you must be aware of environmental concerns. Manufacturing impacts sustainability. Opt for eco-friendly practices, emphasizing resource conservation. Choose materials wisely to minimize environmental impact and support a greener future.

How Do Different Types of Materials Used in Belts and Pulleys Affect Maintenance Requirements and Costs Over Time?

When you choose materials for belts and pulleys, think of it like tending a garden. Quality materials bloom into cost savings, with longevity as flowers that never fade. Maintenance frequency decreases, durability grows, fostering a fruitful, efficient system.

Conclusion

In conclusion, the use of high-quality materials in belts and pulleys is essential for optimal performance and longevity. The durability of pulley materials directly impacts the efficiency and reliability of the system.

Selecting premium materials is non-negotiable for ensuring smooth operation and minimal maintenance. Remember, choosing inferior materials is like playing with fire – it's a recipe for disaster!

Always prioritize quality materials for a stronger, more reliable belt and pulley system.