Why Is My Car's Serpentine Belt Failing?

Ever wondered why your car's serpentine belt keeps failing?

It's frustrating when unexpected breakdowns happen, leaving you stranded.

The culprit might not be what you think.

Let's unravel the mystery behind the common reasons for serpentine belt failures, shedding light on preventive measures and maintenance practices that could save you from future car troubles.

Key Takeaways

- Squealing noises signal belt wear and potential failure.

- Regular tension and alignment checks prevent belt issues.

- Misaligned pulleys accelerate belt wear and must be corrected promptly.

- Environmental factors and neglect contribute to serpentine belt failure.

Common Signs of Serpentine Belt Wear

If you notice any squealing noises coming from the engine area of your car, it may indicate signs of serpentine belt wear. Belt noise can be a clear indicator that your serpentine belt is wearing out, affecting the performance of your vehicle.

The serpentine belt is vital for powering essential components like the alternator, power steering pump, and air conditioning compressor. When the belt starts to wear, it can slip or lose grip on these components, leading to decreased performance and potential breakdowns.

Regular belt replacement is key to avoiding these issues. Maintenance schedules provided by manufacturers typically recommend replacing the serpentine belt every 60,000 to 100,000 miles, but inspecting it regularly for signs of wear and tear is critical.

Ignoring belt wear can result in sudden belt failure, leaving you stranded on the road. By staying proactive and addressing any belt noise promptly, you can guarantee the continued performance and reliability of your vehicle.

Inspecting Belt Tension and Alignment

Inspecting belt tension and alignment guarantees proper functioning of the serpentine belt system in your vehicle, preventing issues that could lead to breakdowns. Proper maintenance of belt tension and alignment is vital. Here are some key points to take into account:

- Regular Inspections: Check the belt for signs of wear such as cracks, fraying, or glazing.

- Correct Tension: Make sure the belt is neither too loose nor too tight to prevent premature wear.

- Alignment: Verify that the belt aligns properly with all pulleys to avoid unnecessary stress.

- Belt Condition: Look for any signs of misalignment that could cause uneven wear.

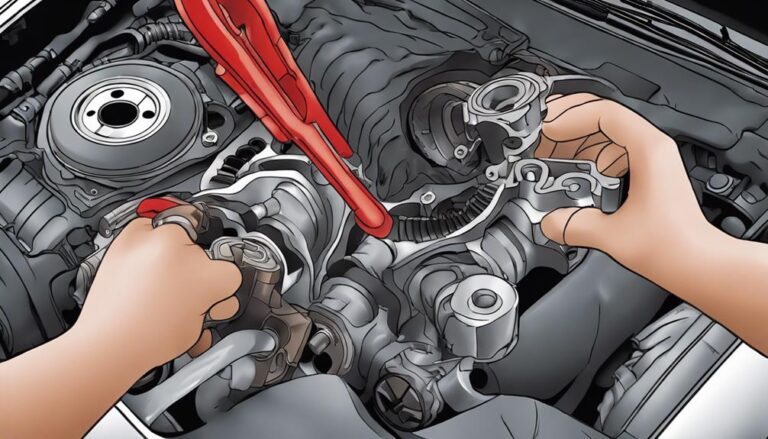

- Tension Adjustment: If the belt is loose, adjust the tension according to the manufacturer's specifications.

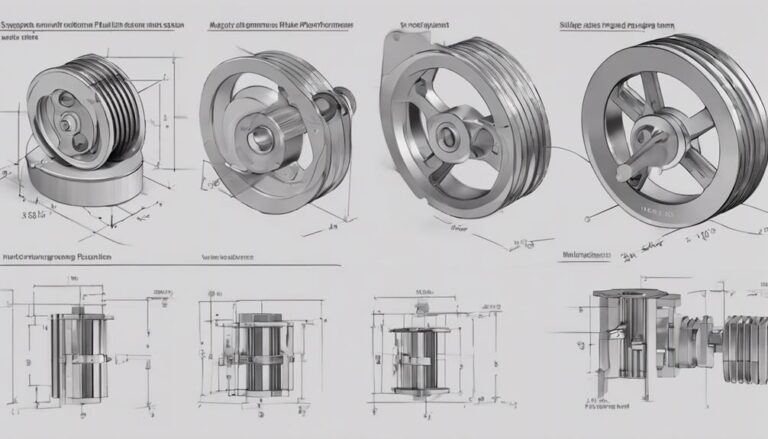

Checking for Pulley Misalignment

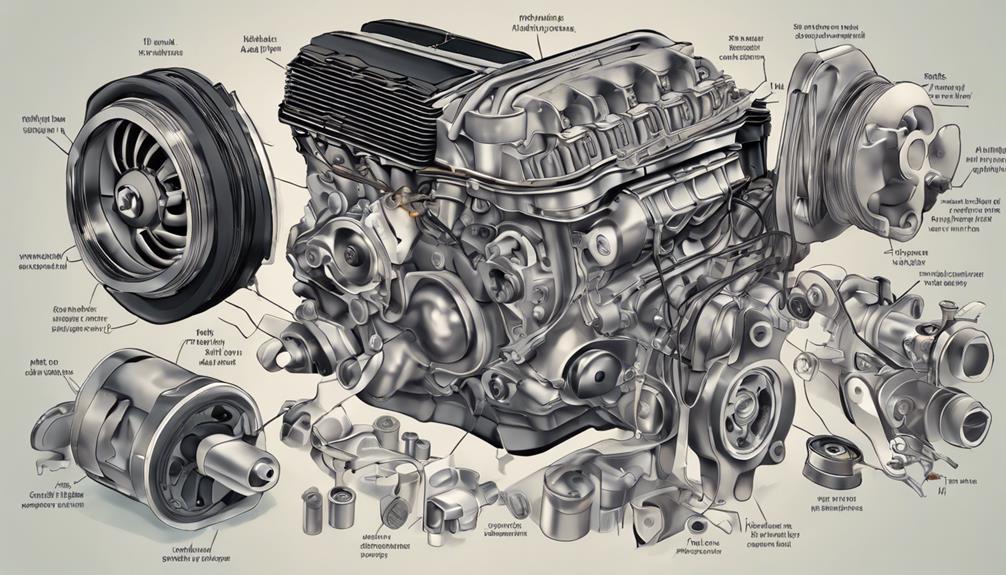

To guarantee peak performance of your vehicle's serpentine belt system, closely examine pulleys for any signs of misalignment. Pulley maintenance is essential in preventing premature belt wear and failure. Misaligned pulleys can cause the serpentine belt to wear unevenly, leading to premature deterioration.

When inspecting the pulleys, make sure they're correctly aligned both horizontally and vertically. Use a straight edge or laser alignment tool to check for any deviations. If misalignment is detected, it's vital to address it promptly to prevent further damage to the belt.

In cases of severe misalignment, belt replacement may be necessary to avoid future issues. Regularly checking for pulley misalignment as part of your maintenance routine can prolong the life of your serpentine belt and ensure the smooth operation of your vehicle. Remember, a well-maintained pulley system is key to preventing costly repairs down the road.

Assessing Belt Age and Condition

Properly evaluating the age and condition of your car's serpentine belt is important for ensuring top performance and preventing potential issues. When appraising your belt, consider the following:

- Visual Inspection: Look for signs of wear such as cracks, fraying, or glazing on the belt surface.

- Belt Tension: Check the tension of the belt by pressing down on it; it should have just the right amount of give.

- Mileage: Keep track of the mileage since the last belt replacement; belts typically need replacement every 60,000 to 100,000 miles.

- Service Records: Review your maintenance records to see when the belt was last replaced or serviced.

- Squealing Noises: If you hear squealing noises coming from the engine, it could be a sign that the belt is slipping or worn out.

Regularly appraising maintenance and knowing when to schedule a belt replacement can prevent unexpected breakdowns and keep your vehicle running smoothly.

Understanding Potential Causes of Failure

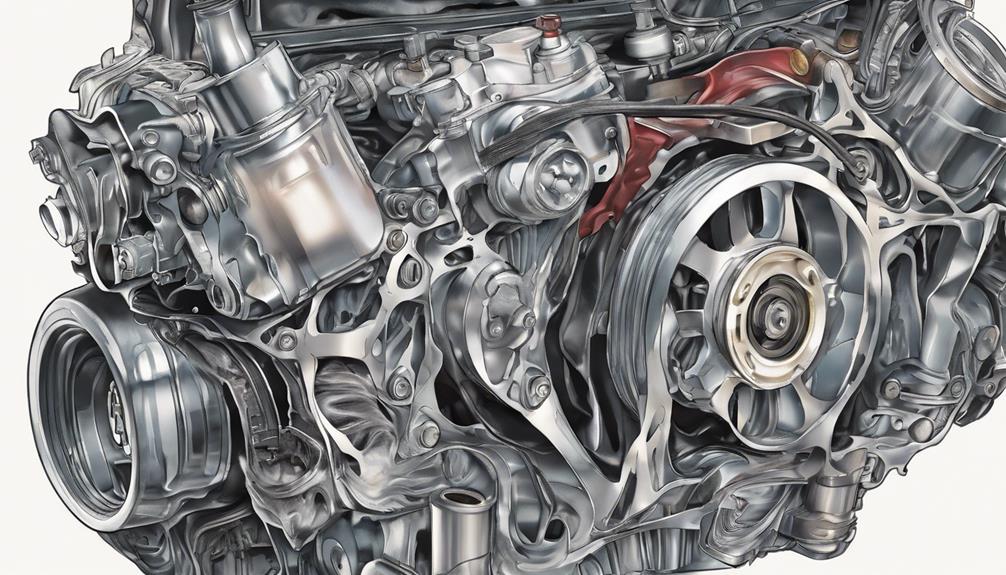

When diagnosing potential causes of serpentine belt failure in your car, scrutinize the belt's surroundings for clues indicating stress or misalignment.

Two key factors contributing to belt failure are belt material degradation and environmental factors impact. Belt material degradation occurs over time due to wear and tear from the engine's rotational forces. Signs of degradation include cracks, fraying, or glazing on the belt surface.

Environmental factors like extreme temperatures, oil leaks, or debris can also impact belt performance. High temperatures can accelerate material breakdown, while oil leaks can cause the belt to slip. Debris such as rocks or dirt can get lodged between the belt and pulleys, leading to misalignment and premature wear.

Regular maintenance checks, including inspecting for these issues, can help prevent serpentine belt failure. By understanding these potential causes, you can proactively address any issues before they result in costly repairs.

Frequently Asked Questions

Can Extreme Weather Conditions, Such as Very Hot or Very Cold Temperatures, Contribute to Serpentine Belt Failure?

Extreme weather conditions, like severe heat or cold, can indeed impact serpentine belt durability. Humidity can accelerate wear, while excessive vibration, common in extreme climates, can strain the belt, leading to failure. Regular inspections are essential.

Are There Any Common Mistakes Made During DIY Serpentine Belt Replacements That Can Lead to Premature Failure?

When replacing a serpentine belt yourself, remember two crucial points: Improper tensioning or incorrect routing can lead to premature failure. Double-check your work meticulously to avoid these missteps and keep your car running smoothly.

How Often Should Serpentine Belts Be Replaced as Part of Regular Maintenance?

You should replace serpentine belts every 60,000 miles or as recommended by your car's manual. Regular inspections for cracks, fraying, or squealing can help prevent costly repairs. Remember, prevention is cheaper than a breakdown.

Can Using Aftermarket or Poor-Quality Belts Increase the Likelihood of Failure?

Using aftermarket or poor-quality belts can greatly impact belt durability. It's important to prioritize quality over price when choosing serpentine belts. Inferior products may fail prematurely, causing damage and inconvenience. Invest in reliable options for lasting performance.

Are There Any Specific Driving Habits or Conditions That Can Put Extra Strain on the Serpentine Belt and Cause It to Fail Sooner?

Driving habits like sudden acceleration and braking, or regularly driving in extreme temperatures or dusty conditions can strain the serpentine belt, leading to premature failure. Such environmental factors increase wear and tear.

Conclusion

To sum up, when your car's serpentine belt fails, it can lead to a breakdown on the road.

By recognizing the signs of wear, inspecting tension and alignment, checking for pulley misalignment, and evaluating age and condition, you can prevent potential causes of failure.

Stay proactive in maintaining your serpentine belt to avoid the inconvenience of a breakdown and make sure your car runs smoothly on the road.