7 Best Indicators of a Failing Drive Belt

Did you know that a failing drive belt is one of the leading causes of vehicle breakdowns, with up to 60% of roadside assistance calls related to this issue?

When it comes to keeping your car running smoothly, recognizing the early warning signs of a failing drive belt can save you time, money, and frustration.

From unusual squealing sounds to sudden engine stalling, being aware of these indicators can help you address the problem before it escalates.

Key Takeaways

- Unusual squealing sounds signal belt tension or alignment issues.

- Visible cracks indicate wear and potential failure.

- Engine overheating may result from a failing drive belt.

- Power steering problems like stiffness or fluid leaks can signify belt issues.

Unusual Squealing Sounds

If you hear unusual squealing sounds coming from your vehicle's engine area, it may indicate a failing drive belt. The squealing is often a result of improper belt tension or misalignment, causing wear on the belt.

To address this issue, you should first check the belt tension to make sure it's within the manufacturer's recommended range. If the tension is too loose or too tight, it can lead to premature belt wear and ultimately failure. Proper belt alignment is also important in preventing squealing noises. Make sure the belt is correctly aligned on all pulleys to avoid unnecessary friction and wear.

If despite proper tension and alignment the squealing persists, it may be time for a belt replacement. Regularly inspecting the drive belt for signs of wear and addressing any issues promptly can prevent more significant problems down the road.

Visible Cracks or Damage

When inspecting your drive belt, look for visible cracks or damage as these are clear signs of wear and potential issues.

Cracks can indicate the belt is nearing the end of its lifespan, while damage can directly affect the belt's performance.

Regular inspection for these visible signs is important for preventative maintenance and avoiding unexpected breakdowns.

Cracks Indicate Wear

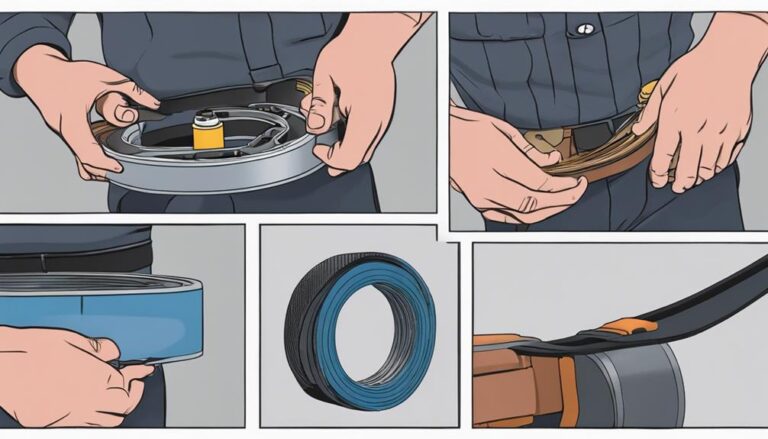

Inspect the drive belt for visible cracks or damage to identify signs of wear indicating potential failure. When evaluating cracks on your drive belt, consider the following:

- Depth: Deeper cracks indicate more advanced wear.

- Location: Cracks near the edges may lead to sudden failure.

- Length: Longer cracks suggest increased stress on the belt.

- Pattern: Multiple small cracks can be as detrimental as a single large one.

Understanding these aspects can help you determine the severity of the wear on your drive belt. Remember, cracks can be early indicators of a failing belt, so timely inspection and replacement are essential to prevent unexpected breakdowns.

Damage Affects Performance

Visible cracks or damage on a drive belt can greatly impact its performance. When neglected, these issues can lead to decreased engine efficiency and overall drive belt functionality. The performance impact of such damage is significant, causing the belt to slip or even break under stress, ultimately affecting the operation of various engine components.

Maintenance neglect is often the root cause of these visible signs of wear, highlighting the importance of regular inspection and timely replacement of drive belts. To guarantee top engine efficiency and prevent unexpected breakdowns, it's vital to address any visible cracks or damage promptly. By proactively maintaining drive belts, you can enhance the longevity and reliability of your vehicle's engine system.

Inspection for Maintenance

Regular inspection of drive belts is important to maintaining peak performance and preventing potential failures caused by visible cracks or damage.

Here's how you can guarantee your drive belt remains in top condition:

- Visual Examination: Perform routine inspections for any visible cracks, fraying, or glazing on the belt surface.

- Tension Check: Regularly check the belt tension to guarantee it's within the manufacturer's recommended range.

- Alignment Verification: Verify that the belt is properly aligned on all pulleys to prevent uneven wear.

- Replacement Schedule: Follow a preventive maintenance schedule to replace the drive belt before it shows signs of significant wear or damage.

Engine Overheating

If your engine is consistently running hot, it could be a sign of a failing drive belt. When the drive belt is worn out or slipping, it can lead to issues with the cooling system, causing the engine to overheat. Two key factors to check in this situation are coolant levels and radiator blockage.

Low coolant levels are often a result of a failing drive belt since it can hinder the proper functioning of the water pump, which circulates coolant through the engine to maintain ideal temperatures. Additionally, if the drive belt is slipping, the water pump may not operate efficiently, leading to inadequate cooling and engine overheating.

Radiator blockage is another consequence of a failing drive belt. A worn-out belt can cause the water pump to underperform, resulting in poor circulation of coolant through the radiator. This inefficiency can lead to overheating as the radiator is unable to dissipate heat effectively. Regularly checking the drive belt can help prevent these issues and make sure your engine stays cool.

Power Steering Issues

If you notice your steering wheel becoming stiff and difficult to turn, hear a squealing noise when making turns, or observe fluid leaks under your car, these could be indicators of power steering issues.

Stiff steering may signal a lack of hydraulic assistance, while the squealing noise could indicate belt slippage. Fluid leaks, often a result of a failing hose or seal, can lead to a drop in power steering fluid levels and compromised steering function.

Steering Wheel Stiffness

Experiencing stiffness in your steering wheel could indicate potential power steering issues. This symptom is critical as it directly impacts your ability to control the vehicle safely. Here are four key aspects to ponder:

- Steering Wheel Vibration: If you feel vibrations through the steering wheel, it may point to alignment issues that need immediate attention.

- Alignment Problems: Misaligned wheels can lead to a stiff steering wheel, affecting your driving experience.

- Unresponsive Steering: Difficulty in turning the wheel signifies safety concerns, and prompt action is necessary.

- Safety Implications: Power steering problems can compromise your ability to navigate effectively, posing risks on the road.

Addressing steering wheel stiffness promptly is vital to guarantee a safe and smooth driving experience.

Squealing Noise When Turning

Steering wheel stiffness can be accompanied by a squealing noise when turning, indicating potential power steering issues that require immediate attention. This squealing noise is often a result of improper belt tension or inadequate lubrication levels within the power steering system.

Insufficient belt tension can cause the belt to slip on the pulleys, leading to the squealing sound. Similarly, low lubrication levels can result in increased friction, causing the belt to produce noise when the steering wheel is turned.

To address this problem, it's essential to check the belt tension and lubrication levels regularly. Ignoring these issues can not only worsen the squealing noise but also lead to more severe power steering complications in the future.

Fluid Leaks Under Car

Inspect the underside of your vehicle for signs of fluid leaks, as they may indicate underlying power steering issues. If you notice fluid pooling under your car, it could be a symptom of power steering problems. Here's what you need to know:

- Causes: Fluid leaks can be caused by worn-out seals or hoses in the power steering system.

- Prevention: Regularly check the power steering fluid level and have the system inspected during routine maintenance to prevent leaks.

- Repair: Repairing power steering fluid leaks involves replacing damaged components and resealing connections.

- Cost: The cost of repairing power steering fluid leaks can vary depending on the extent of the damage, ranging from $150 to $500.

Stay proactive to avoid costly repairs and maintain your vehicle's performance.

Battery Light Illumination

When the battery light on your dashboard illuminates, it often indicates a potential issue with the drive belt system. This warning light is important, as it can signal problems related to the electrical components of your vehicle. If the drive belt that powers the alternator, which charges the battery, is failing, it can lead to the battery light coming on. Below is a table summarizing why the battery light might illuminate due to drive belt issues:

| Possible Cause | Description | Action |

|---|---|---|

| Worn-out Drive Belt | A worn-out belt can slip, leading to alternator inefficiency | Replace the belt |

| Loose Drive Belt Tension | Insufficient tension can cause slippage | Adjust tension |

| Cracked Drive Belt | Cracks can weaken the belt, affecting its grip | Replace the belt |

If you notice the battery light on, it's advisable to address the underlying drive belt issue promptly to prevent further electrical problems.

A/C Not Functioning Properly

If your vehicle's A/C isn't functioning properly, it may be a sign of underlying issues with the cooling system. When the A/C fails, it can be a frustrating experience, especially during hot weather.

Here are some key reasons why your A/C mightn't be working correctly:

- Refrigerant Leak: A common issue leading to A/C problems is a refrigerant leak. Low refrigerant levels can hinder the system's ability to cool the air effectively, resulting in warm air blowing from the vents.

- Blower Motor Malfunction: The blower motor is responsible for pushing the cooled air into the cabin. If the blower motor malfunctions, you may experience weak airflow or no airflow at all from the vents.

Addressing these issues promptly can help restore your A/C system's functionality and guarantee a comfortable driving experience. If you suspect any of these problems, it's advisable to have a professional mechanic inspect and repair your A/C system to avoid further complications.

Sudden Engine Stalling

Experiencing sudden engine stalling can be a concerning indication of potential issues with your vehicle's overall performance. Engine misfiring, a common cause of sudden stalling, can be linked to drive belt efficiency problems. When the drive belt responsible for powering essential components like the alternator and water pump starts to fail, it can lead to engine misfires and eventual stalling. If you notice your engine stalling unexpectedly, it's important to conduct a thorough diagnostic check to pinpoint the root cause promptly.

Additionally, sudden engine stalling can also impact fuel efficiency. A failing drive belt can cause components like the water pump to malfunction, leading to the engine overheating and burning more fuel than necessary. To guarantee fuel efficiency and prevent further damage to your vehicle, addressing drive belt issues promptly is essential. By recognizing the signs of sudden engine stalling and acting swiftly to address them, you can maintain your vehicle's performance and prolong its lifespan.

Frequently Asked Questions

Can a Failing Drive Belt Cause Other Parts of the Car to Malfunction?

If your drive belt fails, it can lead to malfunctions in other parts of your car. Regular maintenance and timely replacement are important to prevent this issue. Neglecting drive belt care may result in costly repairs.

How Often Should Drive Belts Be Inspected for Wear and Tear?

Regularly check drive belts for wear. Inspect every 30,000 miles or as advised in your manual. Listen for squeals or visible damage. Replace if needed. Proper maintenance avoids unexpected breakdowns, ensuring smooth drives.

Are There Any DIY Methods for Checking the Condition of a Drive Belt?

To check a drive belt yourself, perform a DIY visual inspection. Look for cracks, fraying, or missing ribs. Check for proper tension and alignment. Replace if signs of wear are present. Regular DIY diagnostics help prevent drive belt failure.

What Are the Potential Consequences of Ignoring Signs of a Failing Drive Belt?

Ignoring signs of a failing drive belt can lead to severe consequences. Neglected maintenance can result in sudden breakdowns, loss of power steering, engine overheating, and damage to other components. Regular inspections and timely replacement are essential.

Is It Possible for a Drive Belt to Fail Suddenly Without Any Warning Signs?

Can a drive belt fail suddenly without any warning signs? It is possible but uncommon. Most failing drive belts exhibit symptoms like squealing or visible wear before sudden failure. Regular inspection can help detect issues early.

Conclusion

In summary, when it comes to your drive belt, prevention is better than cure. Remember the old adage: 'A stitch in time saves nine.'

By paying attention to the indicators of a failing drive belt and addressing them promptly, you can avoid costly repairs and potentially dangerous situations on the road.

Stay vigilant and proactive in maintaining your drive belt to guarantee the smooth operation of your vehicle.