Ensuring Drive Belt Performance: 3 Maintenance Tips

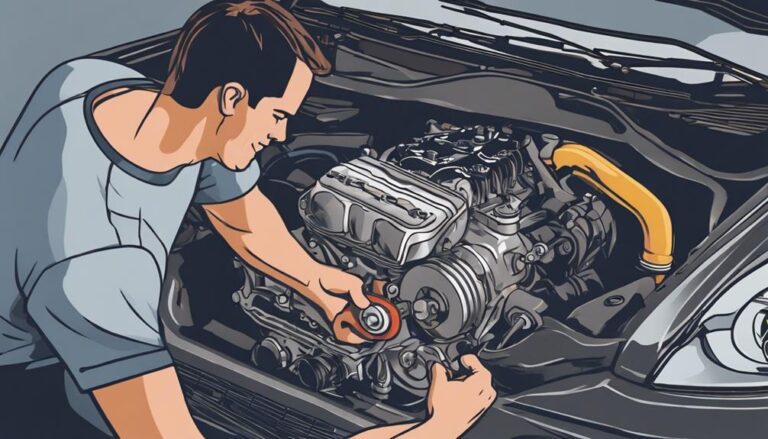

When it comes to ensuring drive belt performance, regular maintenance is key. Checking tensioner alignment, inspecting for wear, and following replacement guidelines are crucial steps.

But how do you know if your drive belt is really up to par?

Let's explore three maintenance tips that will keep your drive belt in top condition, ensuring excellent performance and longevity for your vehicle.

Key Takeaways

- Regular maintenance checks are crucial for optimal drive belt performance.

- Proper tensioner alignment is essential to prevent issues and ensure longevity.

- Timely inspection for wear and adherence to replacement guidelines are vital.

- Following maintenance tips enhances drive belt efficiency and extends its lifespan.

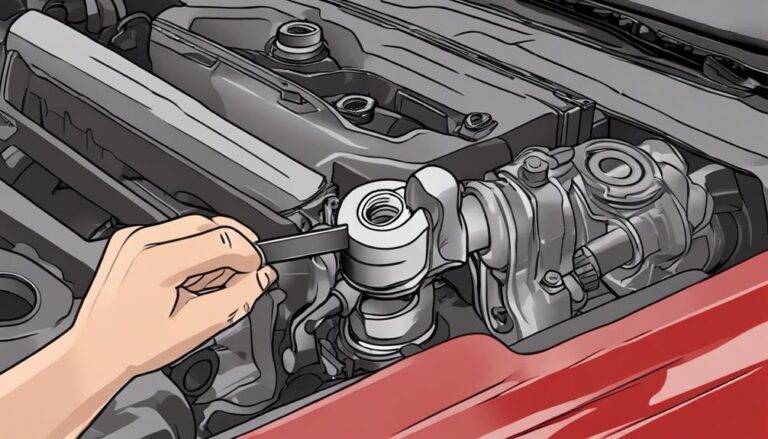

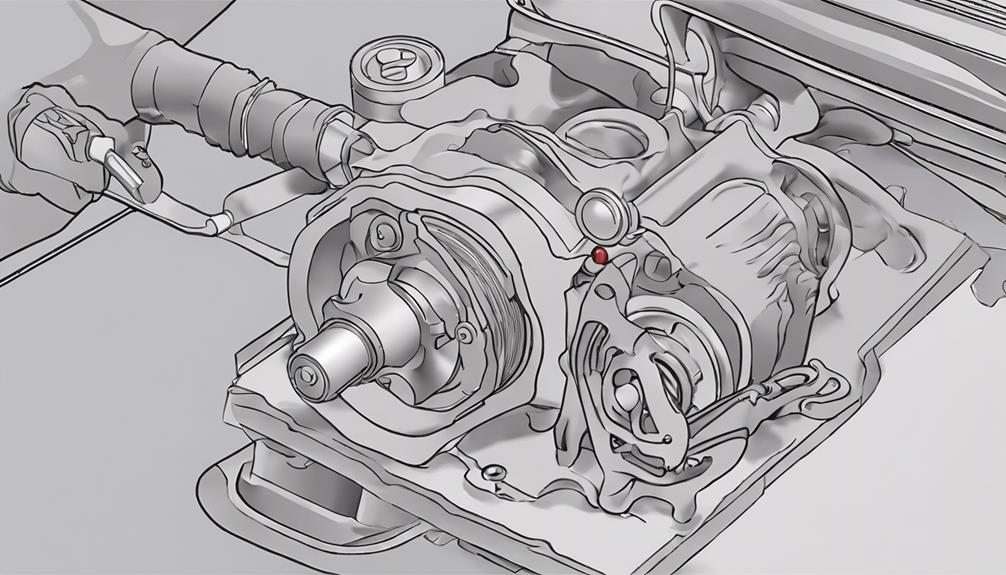

Importance of Tensioner Inspection

When maintaining drive belt performance, it's important to regularly inspect the tensioner to guarantee peak functionality. Tensioner adjustment plays a vital role in ensuring the drive belt operates optimally. To begin, conduct regular performance monitoring on the tensioner to identify any issues promptly. This involves checking for proper alignment, tension, and wear. Correct tensioner adjustment is crucial for preventing slippage, which can lead to decreased performance and potential damage to the belt and other engine components.

Performance monitoring should be done at regular intervals, especially after any maintenance work or when unusual sounds are detected. A well-adjusted tensioner promotes efficient power transmission and extends the lifespan of the drive belt. Neglecting tensioner inspection can result in increased wear on the belt, reduced power output, and even complete system failure. By prioritizing tensioner adjustment and performance monitoring, you can ensure the smooth operation of your drive belt system and prevent costly repairs down the line.

Signs of Tensioner Wear

Inspect the tensioner regularly to detect signs of wear that may indicate the need for adjustment or replacement.

The tensioner plays a critical role in maintaining proper tension in the drive belt system, ensuring optimal performance and longevity.

Signs of tensioner wear can include unusual noises coming from the engine area, visible cracks or damage on the tensioner arm, or inconsistent belt tension.

Monitoring the tensioner functionality is important as it directly impacts the overall efficiency of the drive belt system.

A worn tensioner can lead to belt slippage, decreased power transmission, and potential damage to other engine components.

Understanding the tensioner lifespan is essential for preventive maintenance.

While tensioners are designed to last a long time, factors such as high mileage, extreme temperatures, or improper installation can accelerate wear.

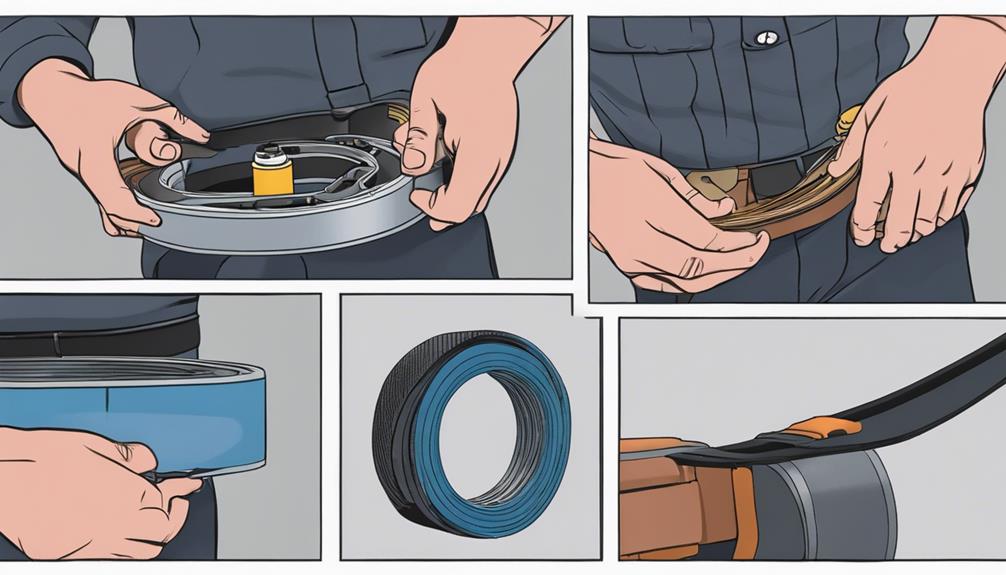

Tensioner Replacement Guidelines

For best drive belt system performance and longevity, follow the following tensioner replacement guidelines.

- Monitor Tensioner Lifespan: Keep track of the tensioner's maintenance schedule and recommended replacement intervals. Tensioners have a finite lifespan and replacing them preemptively can prevent belt slippage and breakage.

- Conduct Regular Maintenance: Make sure the tensioner is inspected during routine maintenance checks. Look for signs of wear such as noise, vibration, or irregular belt wear patterns. Addressing these issues promptly can extend the lifespan of both the tensioner and the drive belt.

- Address Tensioner Troubleshooting: If you encounter tensioner-related problems such as misalignment or insufficient tension, troubleshoot and resolve them promptly. Adjusting the tensioner or replacing it with a new one can prevent further damage to the drive belt and other components in the system.

Frequently Asked Questions

Can I Use a Belt Dressing Spray to Improve the Performance of My Drive Belt?

Yes, you can. Using a belt dressing spray can help improve your drive belt's performance. It aids in belt lubrication and can extend its lifespan. However, remember that regular tensioner adjustment is important for best drive belt functionality.

How Often Should I Have My Drive Belt Tensioner Inspected?

Inspect drive belt tensioner annually to confirm proper alignment and detect wear early. This maintenance step is essential for preventing belt slipping and premature failure. Addressing tensioner issues promptly can prolong belt lifespan.

What Are the Main Causes of Drive Belt Tensioner Failure?

When it comes to drive belt tensioner failure, two key culprits are belt misalignment and excessive heat exposure. Proper alignment and shielding from heat sources can help prolong the life of your drive belt tensioner.

Is It Possible to Over-Tighten a Drive Belt Tensioner?

You don't want to pull too tightly. Over-tightening the tensioner could strain the belt, shortening its lifespan. Remember, precise tensioner adjustment is key for best belt longevity. Keep it snug, not suffocating.

Are There Any Specific Tools or Equipment Needed for Drive Belt Tensioner Replacement?

When replacing a drive belt tensioner, proper tools and equipment are essential for the job. Guarantee tensioner maintenance by using specialized tools like a belt tension gauge to achieve the correct tension levels.

Conclusion

Make sure your drive belt is ready to go the distance by regularly inspecting and replacing the tensioner.

Just like a well-oiled machine, your car's engine needs proper maintenance to keep running smoothly.

Don't let a faulty tensioner throw a wrench in your plans – stay ahead of the game and keep your drive belt in top shape.

Your car will thank you for it!