Essential Drive Belt and Tensioner Inspection Checklist

When it comes to your vehicle's performance and longevity, neglecting the condition of your drive belt and tensioner could lead to costly repairs and unexpected breakdowns.

Imagine cruising down the road smoothly, only to have your drive belt snap without warning. What happens next could be a nightmare scenario.

Let's explore a detailed checklist that can help you guarantee the reliability of these vital components in your vehicle's engine system.

Key Takeaways

- Regular inspection and timely replacement prevent drive belt breakdowns.

- Proper tensioner function ensures optimal belt performance and longevity.

- Drive belt replacement guidelines promote extended lifespan and efficiency.

- Utilize necessary tools for thorough inspection to maintain drive system health.

Importance of Drive Belt Maintenance

Why is proper maintenance of your drive belt essential for the longevity and performance of your vehicle?

Preventive maintenance of your drive belt is important in ensuring the smooth operation of various engine components. The drive belt, often a serpentine belt in modern vehicles, plays a significant role in powering essential systems such as the alternator, power steering pump, water pump, and air conditioning compressor. Regular inspection and timely replacement can prevent unexpected breakdowns and costly repairs.

Neglecting the maintenance of your drive belt can lead to premature wear and potential failure. The belt lifespan varies depending on the material and quality but typically ranges from 60,000 to 100,000 miles. Factors like extreme temperatures, excessive vibrations, or oil leaks can shorten this lifespan. By adhering to a routine maintenance schedule and visually inspecting the belt for signs of wear, you can extend its longevity and avoid unexpected failures. Remember, a well-maintained drive belt is key to the overall health and performance of your vehicle.

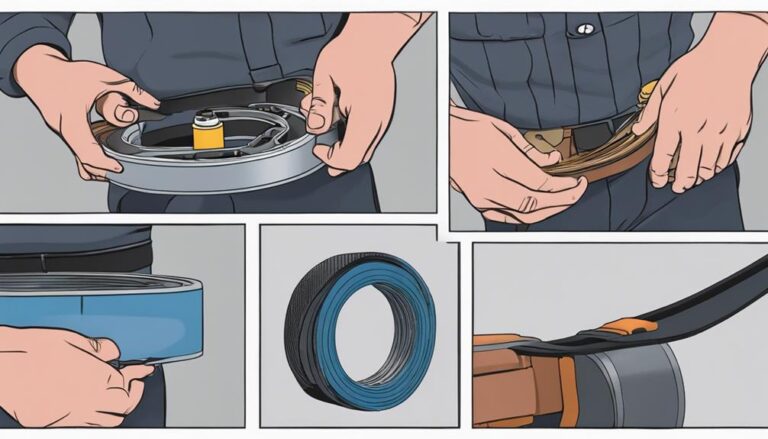

Signs of Drive Belt Wear

Inspect the drive belt regularly for the following signs of wear to guarantee peak performance and prevent potential breakdowns.

- Belt Squeaking: Listen for any unusual squeaking noises coming from the drive belt area. Squeaking can indicate excessive friction due to wear or misalignment.

- Belt Cracking: Check the belt surface for any visible cracks. Cracks indicate aging and wear, reducing the belt's effectiveness in transferring power.

- Tensioner Alignment: Verify the tensioner pulley is in line with the other pulleys. Misalignment can cause uneven wear on the belt, leading to premature failure.

- Tensioner Movement: Test the tensioner's movement by applying pressure. It should move smoothly without excessive play. Stiffness or jerky movements can point to a worn-out tensioner.

- Belt Condition: Examine the overall condition of the belt. Look for fraying, glazing, or any other abnormalities. Addressing these issues promptly can prevent more severe problems down the line.

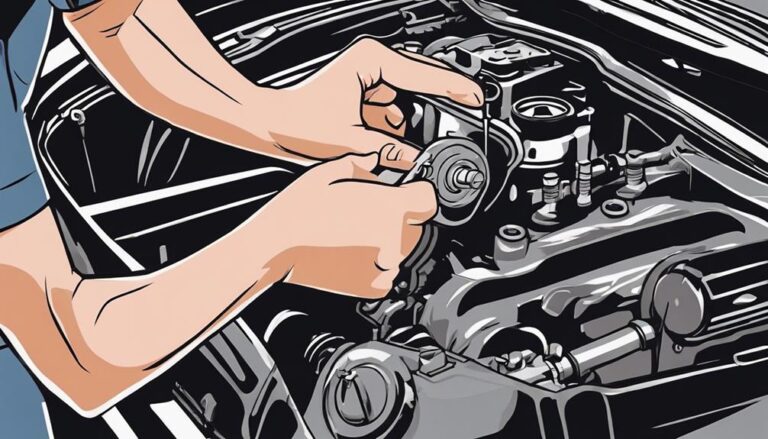

Tensioner Function and Inspection

When evaluating the drive belt and tensioner system, understanding the function and conducting a thorough inspection of the tensioner component is critical to ensuring peak performance and longevity of the system. The tensioner plays a crucial role in maintaining the proper tension of the drive belt, preventing slippage and ensuring efficient power transfer.

To inspect the tensioner effectively, start by checking for any signs of wear indicators. These wear indicators can include visible cracks, excessive wear on the pulley surface, or any abnormal noises during operation.

During inspection, pay close attention to the tensioner's operation. Make sure that it moves freely without any binding or resistance. Any irregularities in the movement could indicate internal damage or wear that may compromise the functionality of the tensioner. Additionally, check for proper alignment of the tensioner with the drive belt to guarantee peak performance.

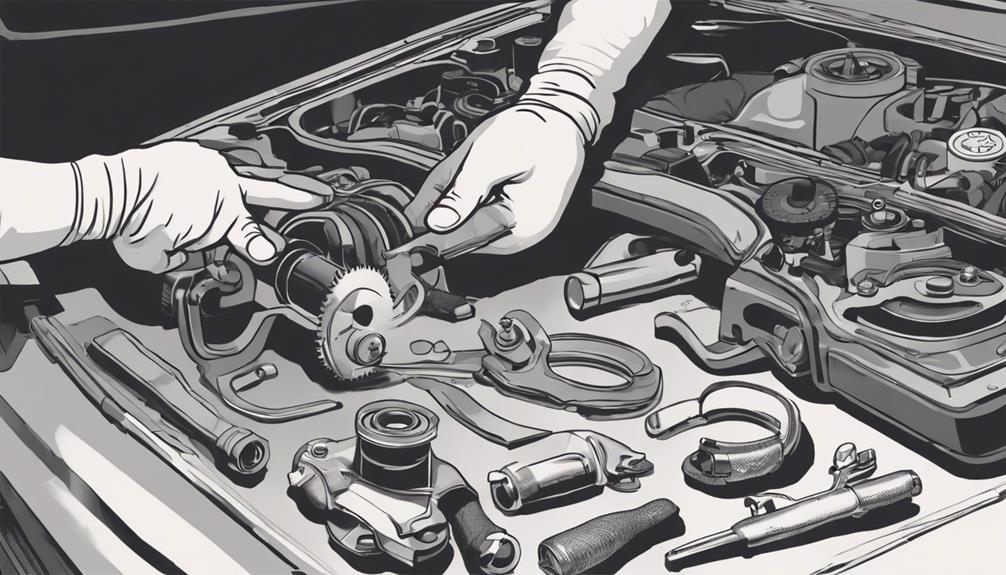

Tools Needed for Inspection

To effectively inspect the tensioner and drive belt system, you'll need specific tools to guarantee a thorough evaluation. Here are the essential tools required for a complete inspection:

- Belt thickness measurements: A caliper or micrometer is critical for accurately measuring the thickness of the drive belt. This measurement helps determine if the belt is within the manufacturer's recommended specifications.

- Tensioner pulley alignment gauge: This tool makes sure that the tensioner pulley is correctly aligned with the other pulleys in the system. Misalignment can lead to premature wear and belt slippage.

- Flashlight or work light: Adequate illumination is necessary to inspect hard-to-reach areas and identify potential issues such as cracks or fraying on the belt.

- Tensioner wrench: A specialized wrench is needed to release tension on the tensioner for easy removal and installation of the belt.

- Safety gloves and goggles: Protect yourself during the inspection process with gloves to avoid cuts and goggles to shield your eyes from debris.

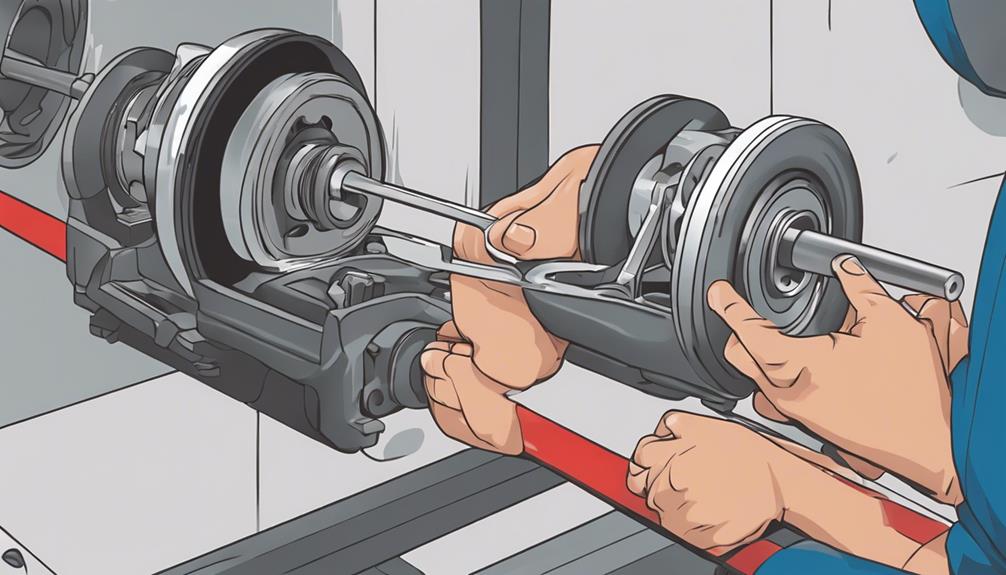

Drive Belt Replacement Guidelines

For effective maintenance of the drive belt system, ensuring proper alignment and tension of the belt is paramount to prevent premature wear and ensure peak performance. Drive belt lifespan can be greatly extended by adhering to proper installation techniques. When replacing a drive belt, it's extremely important to first identify the correct belt for your specific vehicle model. Inspect the belt drive system thoroughly for any signs of damage or misalignment. Before installation, make sure the pulleys are clean and free from any debris that could cause slippage.

When fitting the new drive belt, make sure it follows the correct routing path as specified by the manufacturer. Tension the belt according to the manufacturer's recommendations, using a tension gauge if necessary. Over-tensioning can lead to accelerated wear, while under-tensioning may cause the belt to slip. Once the belt is installed, start the engine and check for proper operation. Regularly inspect the belt for any signs of wear or damage, and address any issues promptly to maintain peak performance and longevity.

Frequently Asked Questions

Can Drive Belt Maintenance Be Done at Home, or Is It Best Left to a Professional Mechanic?

You can tackle DIY maintenance for drive belt at home. However, for complex issues or lack of tools, professional expertise might be wise. Balancing safety, cost, and skills is key to keeping your vehicle in top shape.

How Often Should Drive Belts Be Inspected and Replaced to Ensure Optimal Performance?

Inspect your drive belts annually or every 12,000-50,000 miles. Replace worn or damaged belts promptly to prevent breakdowns. DIY inspection involves checking for cracks, fraying, or looseness. Regular maintenance guarantees peak performance and prolongs drive belt lifespan.

Are There Any Specific Warning Signs That Indicate a Tensioner Is Failing, Aside From Visible Wear on the Drive Belt?

Feeling puzzled about tensioner issues? Listen for odd tensioner noises and watch out for drive belt alignment problems. Don't ignore these warning signs; they could be indicators that your tensioner needs attention.

What Are the Potential Consequences of Neglecting Drive Belt Maintenance and Inspection?

Neglecting maintenance of drive belts can lead to severe consequences. Potential issues include sudden belt failure, engine overheating, loss of power steering, and alternator failure, ultimately resulting in vehicle breakdown and costly repairs.

Are There Any Special Considerations or Precautions to Keep in Mind When Inspecting Drive Belts on Older or High Mileage Vehicles?

When inspecting drive belts on older or high mileage vehicles, be vigilant of belt tension and maintenance intervals. Monitor wear patterns closely. Maintaining proper tension and adhering to maintenance schedules will extend the belt's lifespan.

Conclusion

Now that you have completed your essential drive belt and tensioner inspection checklist, you're well-equipped to guarantee your vehicle's top performance.

Remember, a stitch in time saves nine, so regularly checking and maintaining your drive belt and tensioner can prevent costly repairs down the road.

Stay diligent in your inspections and follow the guidelines for drive belt replacement to keep your vehicle running smoothly.

Happy driving!