10 Best Emergency Roadside Pulley Repair Solutions

When it comes to roadside pulley issues, remember the old saying, 'An ounce of prevention is worth a pound of cure.' Knowing the best emergency solutions can save you time and hassle in a pinch.

From quick fixes to long-term solutions, being prepared can make all the difference in getting back on the road swiftly and safely.

So, let's explore these 10 essential pulley repair strategies and confirm you're ready for any unexpected breakdowns.

Key Takeaways

- Regular inspection and maintenance are crucial for preventing pulley system issues.

- Emergency preparedness kits with spare belts and tools are essential for roadside repairs.

- Proper alternator function is vital for the efficient operation of the pulley system.

- Seeking expert advice from mechanics can provide tailored solutions for pulley system repairs.

Immediate Visual Inspection

Perform a thorough visual inspection of your pulley system to assess the extent of the damage and identify any immediate issues that need addressing. Quick inspection tips can help you in this process. Look for visual cues such as fraying or uneven wear on the belts, which can indicate a misalignment or over-tensioning problem. Check for any debris or foreign objects that may be causing the pulley to operate inefficiently. Preventive maintenance is important to avoid unexpected breakdowns.

Troubleshooting tips include checking for any unusual noises or vibrations during operation, as these could point to underlying issues with the pulley system. Inspect the pulleys for any signs of overheating or excessive grease buildup, which could lead to performance issues. Make sure that all components are securely fastened and properly aligned to prevent further damage. By conducting a detailed visual inspection, you can identify potential problems early on and take the necessary steps to address them promptly.

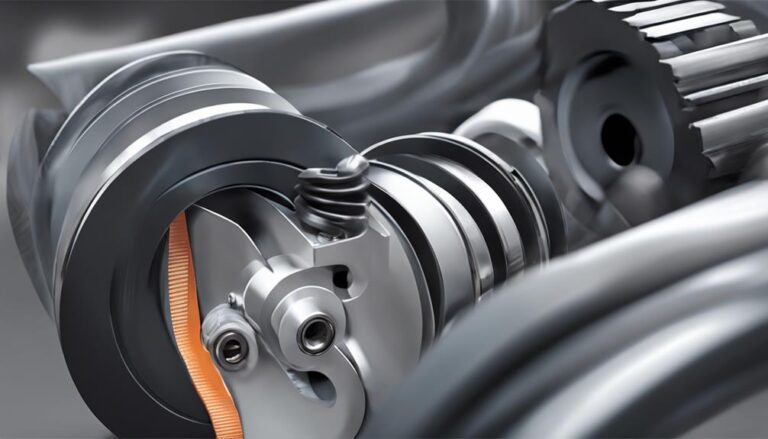

Assess Pulley Alignment

Conduct a precise evaluation of the pulley alignment to pinpoint any deviations that could impact the system's functionality and longevity. When evaluating pulley condition, start by visually inspecting the alignment of the pulleys. Misaligned pulleys can lead to increased wear and tear on the belts, reduced efficiency, and potential breakdowns. Use a straight edge or laser alignment tool to check if the pulleys are in line both horizontally and vertically. Look for any signs of wobbling or uneven spacing between the pulleys, as these indicate alignment issues that need to be addressed promptly.

Pulley maintenance tips include regularly checking the alignment as part of your routine inspections. Make sure the pulleys are securely mounted and that there are no loose bolts or fittings. Clean the pulleys and remove any debris that could affect their alignment. Proper alignment not only guarantees the smooth operation of the system but also extends the lifespan of the pulleys and belts. Regular maintenance and alignment checks are key to preventing roadside emergencies related to pulley malfunctions.

Check Belt Tension

To guarantee peak performance and longevity of your pulley system, it's essential to regularly assess and adjust the tension of the belts. Proper belt tension guarantees efficient power transmission and minimizes wear on the pulleys and belts.

Start by checking the tension of the belts by pressing down on the longest belt span. The ideal tension allows for slight give but shouldn't be too loose or too tight. If the belt feels loose, you'll need to adjust the tension by using the appropriate tools.

Over time, belts can stretch, especially if they aren't well maintained or if they're subjected to heavy loads. Belt lubrication is also critical in maintaining the tension and reducing friction between the belt and the pulleys.

Regularly inspecting and adjusting the tension of your belts will optimize the performance of your pulley system and prevent unexpected breakdowns on the road.

Carry Spare Belt and Tools

Carrying a spare belt and the necessary tools is essential for ensuring you can quickly address any pulley system issues that may arise during your travels. Preventive maintenance is key to avoiding being stranded due to a broken belt. Having spare parts readily available can save you time and money, especially in emergency repair situations where roadside assistance may not be immediately accessible.

To be fully prepared, consider including the following items in your emergency roadside kit:

| Spare Parts | Tools | Additional Equipment |

|---|---|---|

| Extra belts | Wrench set | Flashlight |

| Tension gauge | Pliers | Gloves |

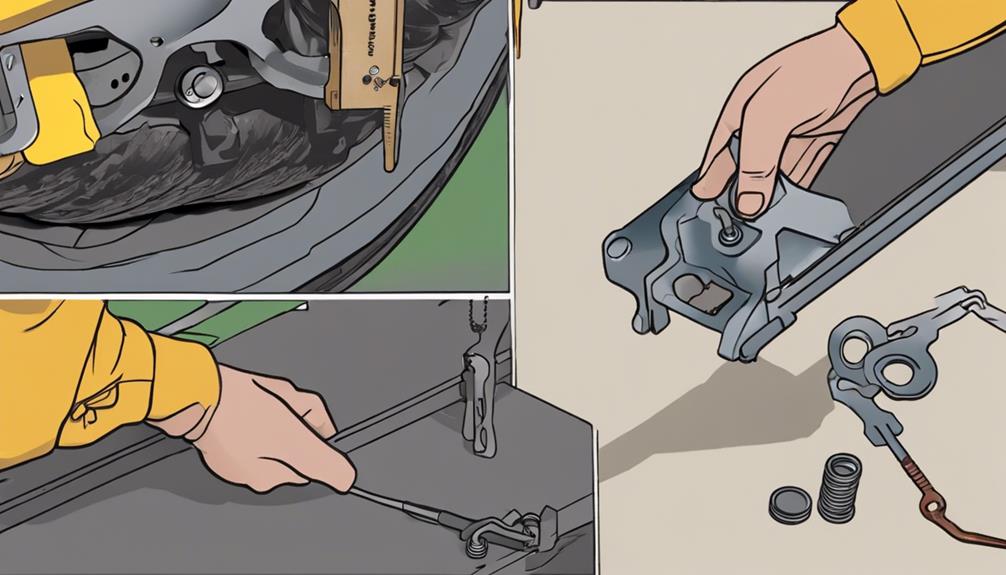

Temporary Belt Fix

Consider a quick and effective temporary fix for a belt issue using readily available tools and materials. When faced with a belt problem on the road, you can utilize these emergency solutions to get you back on track:

- Nylon Stocking or Pantyhose: Cut a piece from a nylon stocking or pantyhose and use it as a makeshift belt. Wrap it tightly around the pulleys to provide temporary functionality until a proper replacement can be installed.

- Duct Tape: In a pinch, duct tape can act as a temporary fix for a belt issue. Securely wrap the duct tape around the pulleys and the belt area, ensuring it's tight enough to maintain proper tension.

- Binder Twine or Rope: If you have binder twine or a strong rope available, you can use it to create a makeshift belt. Tie the twine or rope securely around the pulleys, mimicking the path of the original belt for a temporary solution.

These quick fixes are essential for roadside repairs and can help you address belt maintenance issues promptly in emergency situations.

Assess Pulley Damage

Inspect the pulley system meticulously to evaluate the extent of damage. Look for signs of wear and tear, such as cracks, chips, or misalignment.

Damage Severity Assessment

Evaluating the severity of pulley damage is essential for determining the appropriate repair solutions. When evaluating pulley damage, consider the following:

- Fractures: Inspect the pulley for any visible cracks or fractures, as they can weaken the structure and lead to failure.

- Wear Patterns: Look for uneven wear patterns on the pulley surface, which could indicate misalignment or lack of lubrication.

- Alignment Check: Measure the alignment of the pulley with surrounding components to identify any issues that may be causing damage.

Identifying Worn-Out Parts

To accurately pinpoint worn-out parts in a pulley system, focus on identifying subtle signs of deterioration that could impact its performance and longevity. Pulley wear analysis is essential in preventing unexpected breakdowns. Troubleshooting techniques involve inspecting for irregularities such as excessive noise, vibration, or wobbling during operation. Look for visible signs of wear like fraying or cracking on the pulley surface, which indicate a need for immediate attention. Additionally, check for any misalignment issues that may cause uneven wear on the pulley components. Regular maintenance and early detection of worn-out parts can save you from costly repairs or replacements down the road.

| Signs of Worn-Out Parts | Importance |

|---|---|

| Excessive noise during operation | Indicates potential issues |

| Visible fraying or cracking | Urgent need for repair |

| Vibration or wobbling | Sign of wear and tear |

| Misalignment | Causes uneven wear |

| Regular maintenance | Prevents costly repairs |

Replace Pulley Bearings

When replacing pulley bearings, make sure that the pulley is securely fastened to prevent any movement during the process. Proper handling and attention to detail are important when replacing pulley bearings to ensure best performance and longevity of the system.

Here are some essential tips to guide you through the process:

- Selecting the Right Bearings: Make sure you choose bearings that match the specifications of your pulley system to guarantee a proper fit and functionality.

- Proper Disassembly Techniques: Carefully disassemble the pulley system, keeping track of each component and the order in which they're removed to facilitate smooth reassembly.

- Applying Correct Lubrication: Use appropriate lubricants recommended for your specific bearings to minimize friction and wear, extending the lifespan of the pulley system.

Secure Pulley Bolts

Make sure that the pulley bolts are tightly fastened using a torque wrench to prevent any potential loosening during operation. This step is essential in securing the pulley in place and ensuring its proper function. By tightening the bolts to the manufacturer's recommended torque specifications, you can prevent future issues such as pulley misalignment or detachment while the vehicle is in use.

As part of DIY troubleshooting tips, inspect the pulley bolts regularly for any signs of wear or corrosion. If you notice any issues, such as rust or stripped threads, replace the bolts immediately to maintain the pulley's integrity. Additionally, consider using thread-locking adhesive when installing new bolts to provide extra security against loosening over time.

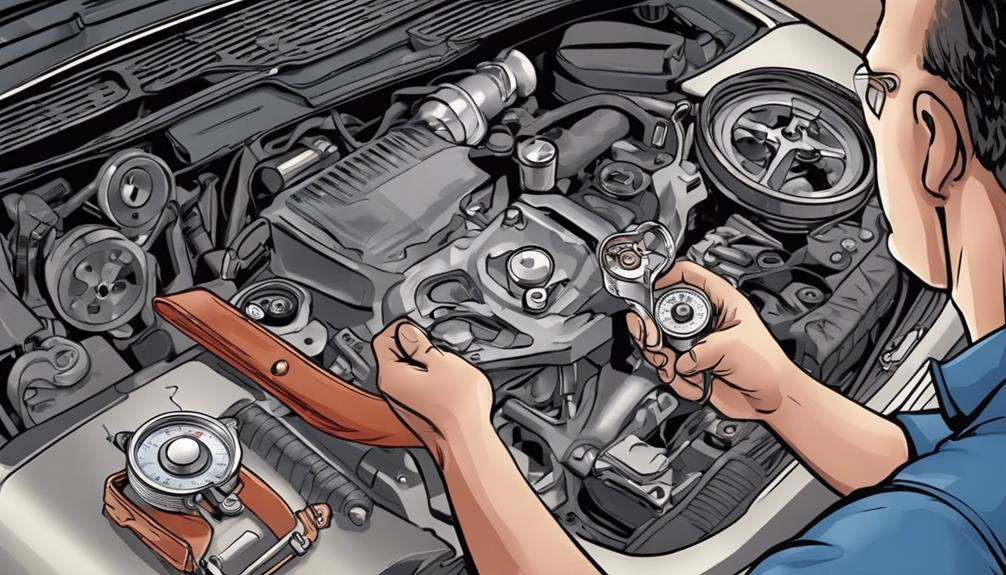

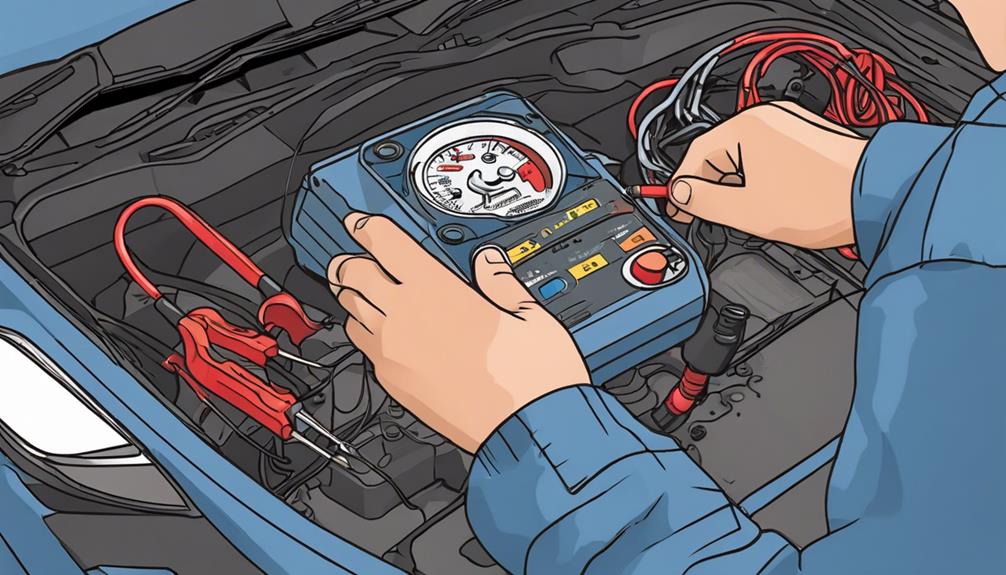

Assess Alternator Function

Assess the alternator function by conducting a thorough inspection of its components and electrical output.

To diagnose the alternator effectively, follow these troubleshooting techniques:

- Verify Belt Tension: Verify the alternator belt is properly tensioned to drive the pulley efficiently.

- Examine Wiring Connections: Examine the electrical connections to the alternator for any signs of corrosion or damage.

- Measure Output Voltage: Measure the alternator's output voltage using a multimeter to verify if it's within the manufacturer's specifications.

Professional Mechanic Consultation

When seeking a professional mechanic's consultation, you gain access to expert advice tailored to your specific roadside pulley repair needs. Mechanics can provide valuable insights and practical tips that can help you address the issue efficiently and effectively.

Their expertise can steer you in the right direction, ensuring a successful resolution to your pulley problem.

Expert Advice Benefits

Seeking guidance from a professional mechanic can provide invaluable insights when dealing with emergency roadside pulley repairs. When experts share their knowledge, you gain access to a wealth of information that can make your repair process smoother and more efficient. Here are some benefits of consulting with a professional mechanic:

- Maintenance Benefits: Mechanics can advise on preventive maintenance practices to avoid future pulley issues.

- DIY Solutions: They can suggest temporary fixes or workarounds to help you get back on the road safely.

- Proper Tools: Mechanics can recommend specific tools or techniques tailored to your situation, ensuring a successful repair.

Expert advice can be the key to overcoming challenging roadside pulley problems effectively.

Mechanics' Tips Shared

Consider consulting with a professional mechanic for valuable insights and tips on addressing emergency roadside pulley repairs efficiently. When facing emergency roadside troubleshooting, mechanics can provide expert advice tailored to your specific situation. They may suggest temporary fixes or workarounds to get you safely back on the road.

Mechanics often have a wealth of knowledge on pulley repair hacks that can prove invaluable in a pinch. From using makeshift tools to improvising solutions, their tips can be a game-changer when dealing with unexpected breakdowns. By tapping into their expertise, you can learn practical techniques to handle pulley-related issues effectively, minimizing downtime and ensuring a smoother journey ahead.

Frequently Asked Questions

Can a Damaged Pulley Cause Other Parts of the Engine to Malfunction?

A damaged pulley can indeed cause other engine parts to malfunction. This impact on performance can lead to potential hazards like overheating or loss of power. Promptly addressing pulley issues is important to prevent further damage.

How Often Should Pulley Bearings Be Replaced to Prevent Breakdowns?

You need to prioritize proper maintenance to keep your pulley system running smoothly. Replacement intervals for pulley bearings vary based on wear and tear, but a good rule of thumb is to check and lubricate them annually.

Are There Any DIY Methods for Temporarily Fixing a Pulley in an Emergency Situation?

In an emergency, you can use common items like zip ties, duct tape, or even a spare belt to create temporary pulley fixes. These emergency pulley hacks can help you get back on the road quickly.

What Are the Signs That Indicate a Pulley Needs to Be Replaced Rather Than Repaired?

If you notice unusual noises, vibrations, or the pulley is wobbling excessively, it's time for replacement. Neglecting these warning signs can lead to severe damage. Regular maintenance can help prevent unexpected failures and guarantee smooth operation.

Can Using the Wrong Size or Type of Belt Cause Further Damage to the Pulley System?

Using the wrong size or type of belt can lead to misalignment and increased friction in the pulley system, causing potential damage. Make sure to check belt compatibility, adjust tension, and analyze friction for peak performance.

Conclusion

In summary, when faced with a roadside pulley repair emergency, it's important to act quickly and efficiently. By following the steps outlined in this guide, you can effectively address the issue and get back on the road safely.

Remember, preparation is key, so always carry spare belts and tools to handle any unexpected situations. With these solutions at your disposal, you'll be able to tackle any pulley problem with ease, turning a potential disaster into a minor inconvenience.