Unraveling the Mystery of Brake Controllers: Understanding the 4 Wires

The four wires on a brake controller are power, ground, brake switch, and brake output. A brake controller is an electronic device that manages the electric brakes in a trailer.

There are four wires on a brake controller that serve different purposes. The power wire provides power to the brake controller, while the ground wire connects it to the vehicle’s frame. The brake switch wire connects the brake controller to the brake switch, which tells the controller when to activate the trailer’s brakes.

Finally, the brake output wire delivers power to the trailer’s electric brakes. It’s important to understand the function of each wire to ensure that the brake controller is installed correctly and functioning properly. In this article, we’ll explore each of these wires in detail and provide tips on how to wire a brake controller to your vehicle.

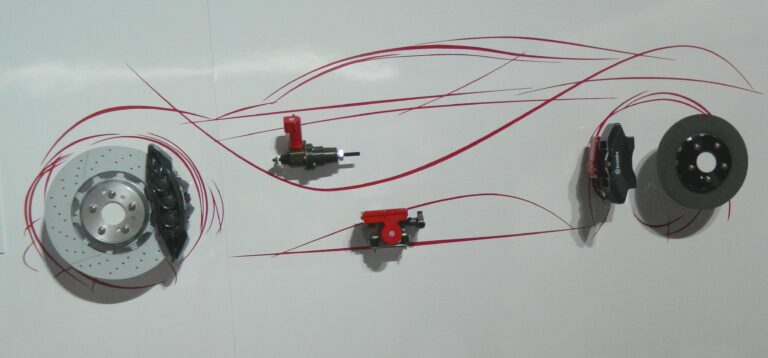

Credit: abc17news.com

What Are Brake Controllers And Why Do You Need Them?

Brake controllers are an essential part of a towing vehicle for smooth and safe brake operations. Brake controllers serve as the main mechanism to control the trailer’s hydraulic or electric brakes, providing an effective way to slow down and stop the vehicle.

If you are new to towing, understanding the importance of brake controllers is crucial to your safety. In this blog post, we will explain the definition of brake controllers, why they are important, benefits of using them, and common scenarios when brake controllers are needed.

Definition Of Brake Controllers

Brake controllers are devices that regulate the amount of braking power applied to the trailer’s wheels when towing. The brake controller is installed in the tow vehicle, which provides an electric signal to the trailer’s brakes when you apply the vehicle’s brakes.

The brake controllers work by applying varying levels of brake force to the trailer’s wheels through an electric circuit. This results in the trailer’s brakes slowing down and stopping according to the vehicle’s speed and braking force.

Explanation Of Their Importance

The importance of brake controllers in towing vehicles cannot be overstressed. They are essential to maintaining the safety of a vehicle and preventing accidents while towing. Below are some reasons why brake controllers are critical:

- They provide smoother and more controlled braking, especially during sudden stops.

- Brake controllers help prevent trailer swaying, which can cause an accident.

- They enhance the balance and stability of the vehicle/towing combination.

- Brake controllers allow for shorter stopping distances, providing more safety on the road.

- They help make uphill towing more efficient by reducing stress on the tow vehicle’s brakes.

Benefits Of Using Brake Controllers

In addition to increasing safety while towing, brake controllers offer numerous benefits that make them an ideal accessory for any towing vehicle. Here are some benefits of using brake controllers:

- Brake controllers help to prolong the life of the trailer’s brakes.

- They help reduce wear and tear on the tow vehicle’s brakes, reducing maintenance costs.

- Brake controllers provide better fuel economy by reducing stress on the tow vehicle’s engine.

- They enhance the overall driving experience by providing a smoother, more controlled braking experience, resulting in less fatigue while driving.

Common Scenarios When Brake Controllers Are Needed

Brake controllers are needed in many different scenarios, some less obvious than others. Here are some of the most common scenarios where brake controllers are needed:

- When towing a trailer that weighs over 1,500 pounds (in many states, this is a legal requirement).

- When towing a trailer with electric brakes, which require a brake controller to operate.

- When transporting heavy cargo that requires extra braking power while moving.

- When towing a trailer on hilly terrain where uphill and downhill movement is common.

Brake controllers are an essential element of towing safety and should be installed on any towing vehicle. They enhance braking performance, reduce wear and tear on the tow vehicle’s brakes, and provide a smoother, more controlled braking experience. Understanding their importance, benefits, and common scenarios when brake controllers are needed is crucial to staying safe while towing.

The Four Wires: Understanding The Basics

Understanding The Four Wires Of Brake Controllers

Brake controllers might seem complicated, but having a basic understanding of the four wires involved in the system will help make sense of it all. These wires work together to make sure the trailer brakes work properly, so it’s crucial to understand what each wire does.

Explanation Of The Four Wires

The four wires in a brake controller system are as follows:

- Ground wire: This wire connects the controller to the vehicle’s frame to ground it properly.

- Power wire: Also called the brake controller lead, it connects the controller to the battery or a 12-volt power source.

- Brake switch wire: This wire is responsible for activating the brake controller when the brake pedal is depressed. Some newer vehicles have electronic brake signals that activate the controller instead of using this wire.

- Brake signal wire: This wire sends the signal to the trailer brakes that they need to be activated and engage the brakes.

Role Of Each Wire In The Braking System

Now that we know what each wire does let’s dive deeper into their individual roles in the braking system:

- Ground wire: This wire is used to ensure that the brake controller has a proper return path so that the system can be grounded to prevent electrical disturbances or fires.

- Power wire: This is the main wire that powers the brake controller, so it is crucial to make sure that it is properly connected to the battery or a 12-volt power source.

- Brake switch wire: The brake switch wire is essential because it ensures that the controller knows when you apply the brakes. If this wire is not connected correctly, the brakes will not activate, or there may be a delay with the trailer brakes engaging.

- Brake signal wire: This wire connects the brake controller to the trailer brakes, sending a signal for them to activate.

How The Wires Work Together

The wires work together seamlessly, and they’re all important. Let’s take a closer look:

- When you apply the brakes in your vehicle, the brake switch wire sends a signal to the brake controller.

- The controller then sends a signal to the trailer brakes through the brake signal wire, causing them to engage.

- The power wire and ground wire work together to provide the necessary power and return path to activate the brakes.

Understanding the four wires in a brake controller system can help you ensure that your brakes are working properly. Be sure to consult your vehicle and trailer owner’s manuals or consult with a professional if you have any doubts about installing or repairing your brake controller system.

Setting Up Your Brake Controller: Installation And Calibration

Preparing For Brake Controller Installation

Before starting to install your brake controller, make sure that you have gathered all the necessary tools and equipment. Follow these steps for a successful installation:

- Gather the following tools and equipment: Wire strippers, crimping tool, drill with drill bits, screwdriver set, wire connectors, zip ties, and silicone sealant.

- Select the appropriate location for mounting the brake controller. It should be within reach and easy to access while driving.

- Locate the brake switch wire in your vehicle by referring to the owner’s manual or visiting online forums for your specific make and model.

- Choose the appropriate wire connector based on the type of wire you are using for your brake controller.

Steps To Install Brake Controllers

After preparing for the installation, follow these steps for a smooth installation process:

- Connect the brake controller to your vehicle’s electrical system by running the wires from the brake controller to the brake switch wire, battery, and ground wire.

- Once you have found the brake switch wire, use a wire stripper to remove a small portion of the coating.

- Connect the brake controller wire to the brake switch wire with a crimping tool. Cover the connection with electrical tape or heat shrink tubing.

- Mount the brake controller in the chosen location using screws and a drill.

- Run a ground wire from the brake controller to the vehicle’s metal chassis.

- Connect the brake controller to the battery with a fuse holder and a 20-amp fuse.

- Test the brake controller to ensure it is functioning correctly by activating the brake pedal and checking the voltage.

Tips For Smooth Calibration

Proper calibration of your brake controller is essential for it to work correctly. Follow these tips for a successful calibration process:

- Start by setting the brake controller to the lowest level (usually zero) and connect it to the trailer.

- Begin driving and gradually apply the brakes to get a feel for the controller’s sensitivity.

- Increase the brake controller setting until you feel that the trailer is stopping smoothly and immediately after the towing vehicle.

- Always test the brake controller on level ground before going on a trip.

- Always follow the manufacturer’s recommendations for calibration procedures.

Safety Precautions To Take While Setting Up The Brake Controller

When setting up the brake controller, it is important to take the necessary safety precautions to prevent injuries and damage to your vehicle and the trailer. Here are some important safety tips to follow:

- Always wear protective gloves, safety goggles, and other safety gear while working on your vehicle.

- Turn off the vehicle’s ignition and disconnect the battery to prevent an electric shock or short circuit.

- Always use the appropriate tools and equipment for the job.

- Do not connect the brake controller to any other electrical device in the vehicle or trailer.

- Test the brake controller in a safe, open, and controlled environment before going on a trip with heavy loads.

Proper installation and calibration of brake controllers is crucial for a safe and comfortable towing experience. Follow these steps, tips, and safety precautions to enjoy your next road trip to the fullest!

Troubleshooting Common Brake Controller Issues

Overview Of Common Issues With Brake Controllers

Brake controllers are essential components that ensure the safety of drivers and passengers by controlling the braking system of their vehicles. However, despite their importance, these controllers may develop issues, such as:

- Brake controller not responding

- Uneven braking

- Trailer brakes locking up

- Difficulty in activating the brakes

Step-By-Step Solutions To Troubleshoot These Issues

If you encounter any of the problems listed above, you can take the following steps to troubleshoot them:

- Check the connection: Ensure that the wires connecting the brake controller to the trailer are correctly attached and free of any damage or wear.

- Adjust the brake controller settings: Make necessary adjustments to brake force, gain, and voltage based on the type of trailer, load capacity, and the brake controller manufacturer’s manual.

- Check the ground connection: Make sure that the brake controller is grounded correctly and free of any corrosion or breakage.

- Verify power source: Check if the brake controller is receiving power from the vehicle’s battery.

- Inspect the brake system: Inspect the brake system of the trailer to check if there is any leak or damage to the brake lines or cylinders.

Expert Tips For Maintaining Brake Controllers To Avoid Issues

Maintenance of brake controllers is crucial to avoid issues that can compromise the driver’s safety and that of other road users. Here are some tips to maintain your brake controller and avoid issues:

- Read the manufacturer’s manual: Read the manual provided by the brake controller manufacturer to understand the installation procedure, maintenance requirements, and troubleshooting steps.

- Test the brake controller regularly: Test the brake controller before every trip to ensure proper function and make necessary adjustments.

- Clean the brake controller: Clean the brake controller regularly to keep it free from corrosion, debris, and dust.

- Inspect the wires: Check the wiring regularly for any wear, damage, or loose connections. Repair or replace any worn or damaged wires.

- Monitor the battery: Check the battery regularly to ensure that it is fully charged and in good condition, as it powers the brake controller.

By following these troubleshooting and maintenance tips for brake controllers, you can avoid problems and ensure your safety on the road.

Frequently Asked Questions For What Are The 4 Wires On A Brake Controller

What Are The 4 Wires On A Brake Controller?

Brake controllers have 4 wires: red, black, white, and blue. The red wire connects to the brake light switch, the black is for ground, the white connects to the negative battery terminal, and the blue wire activates the trailer brakes.

How Does A Brake Controller Work?

A brake controller detects when the tow vehicle is slowing down or stopping and sends an electric signal to the trailer’s brake system, activating the brakes. This ensures that the trailer brakes simultaneously with the tow vehicle, making it easier to control and stop the trailer.

Can I Install A Brake Controller Myself?

While it’s possible to install a brake controller yourself, it’s not recommended unless you’re comfortable with electrical wiring and have some experience. Installing the controller incorrectly could cause it to fail or even damage your vehicle’s electrical system.

Do I Need A Brake Controller For My Trailer?

If your trailer has a gross vehicle weight rating (gvwr) of more than 3,000 pounds, it’s required by law to have a functional brake system that is in sync with the tow vehicle brakes. A brake controller is necessary to achieve this synchronization.

How Do I Choose The Right Brake Controller For My Vehicle?

Choosing the right brake controller depends on the towing capacity, type of trailer, and brake system of your vehicle. Consider factors such as the type of trailer you’re towing, how often you’ll be towing, and whether you have experience with brake controllers when selecting one.

Conclusion

After learning about the four wires on a brake controller, it is clear that each wire plays a crucial role in ensuring that your vehicle stops safely and efficiently. From the power wire that supplies the brake controller with electricity to the brake output wire that sends signals to the trailer’s brakes, every wire serves a purpose.

It’s important to understand how these wires work and how to properly install them to avoid any safety hazards. By following the manufacturer’s instructions and consulting with a professional if necessary, you can ensure that your brake controller is installed correctly and functioning properly.

Remember to always prioritize safety when towing and never hesitate to ask for help if you’re unsure about any aspect of the installation process. With the proper knowledge and equipment, you can confidently tow your trailer and enjoy the journey ahead.