Nitrous Injection Unleashed: Power at Your Fingertips

Unleashing the sheer power of nitrous injection is akin to taming a wild stallion: challenging, yet rewarding. Our journey into this high-octane world dissects the science behind nitrous oxide's power boost, explores the vital components of a nitrous injection system, and offers a comprehensive guide on installation and safety measures. From maximizing performance to troubleshooting, we aim to empower you with the knowledge to harness the untapped potential of nitrous injection, putting raw power at your fingertips.

Key Takeaways

- Nitrous injection increases power output of internal combustion engines.

- Nitrous oxide splits into oxygen and nitrogen, supporting intense combustion of fuel.

- Quantity and timing of nitrous oxide release are crucial for optimal power boost.

- Proper installation, maintenance, and tuning are essential for safe and efficient use of nitrous injection systems.

Understanding the Concept of Nitrous Injection

Before we can delve into the intricacies of nitrous injection and its impact on vehicular performance, it is essential to first understand the basic underlying concept of this powerful technology. Nitrous injection, also known as nitrous oxide injection, is a method used to increase the power output of an internal combustion engine.

In layman's terms, the concept of nitrous injection can be likened to feeding the engine with a potent cocktail of oxygen and nitrogen. When nitrous oxide is heated to approximately 570 degrees Fahrenheit, it splits into its two component parts, releasing additional oxygen into the combustion chamber. This extra oxygen supports a more intense combustion of the fuel, resulting in a sharp increase in horsepower.

The true beauty of nitrous injection lies in its simplicity and versatility. It can be used in virtually any combustion engine, providing an instant and significant boost in power when needed. Nitrous injection offers a level of liberation and control to drivers, allowing them to unlock the full potential of their vehicles with the flick of a switch. Understanding the concept of nitrous injection is the first step in harnessing this potent technology.

The Science Behind Nitrous Oxide Power Boost

Both the quantity of nitrous oxide injected and the precise timing of its release play pivotal roles in achieving the optimal power boost for a vehicle. The science behind nitrous oxide power boost, often termed as NOS power, is rooted in the principles of thermodynamics and combustion kinetics. When nitrous oxide injection is deployed, it decomposes to yield more oxygen, thus supporting the combustion of more fuel and leading to a significant increase in power.

Harnessing the NOS power effectively requires:

- An efficient nitrous oxide injection system that ensures the right quantity of nitrous oxide is delivered.

- A well-calibrated ignition system that guarantees the correct timing for nitrous release.

- A potent fuel system capable of supplying the additional fuel required for nitrous-aided combustion.

- A nitrous purge kit to expel any gaseous nitrous oxide from the feed line before it enters the engine, ensuring a solid stream of nitrous oxide upon activation.

Understanding the science behind nitrous oxide power boost is fundamental to achieving this liberation in power. With the right setup, you can unlock the latent power of your vehicle, providing a remarkable boost that will revolutionize your driving experience.

Components of a Nitrous Injection System

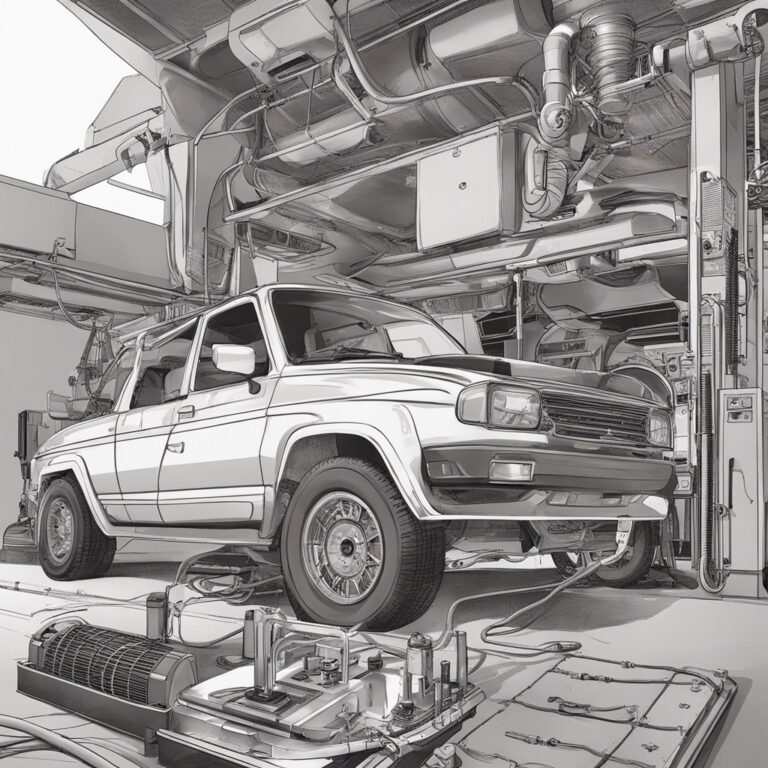

Within a nitrous injection system, several critical components work in harmony, and each plays a vital role in ensuring the efficient and safe delivery of nitrous oxide to the engine.

Firstly, the nitrous bottle is the core of the system, housing the pressurized nitrous oxide. It is typically installed in the trunk, with its valve oriented upwards. The bottle pressure is crucial to the system's performance, as nitrous oxide's effectiveness is directly related to its pressure.

Next, the nitrous lines, made from high-strength braided stainless steel, transfer the nitrous oxide from the bottle to the engine. The solenoids, acting as electronically controlled valves, regulate the flow of nitrous and fuel into the engine. These are typically mounted as close to the intake manifold as possible to reduce lag.

The nitrous injection nozzle is where the magic happens. This component atomizes the nitrous and fuel, injecting it directly into the air intake stream. The system is controlled by the activation switch, which can be manually operated or automatically triggered by throttle position or RPM.

Lastly, the system includes a blow-off valve, crucial for safety, releasing pressure if the system exceeds safe levels. Each component intricately designed, ensuring the power of nitrous injection is efficiently and safely harnessed.

Installation Process for a Nitrous Injection Kit

Transitioning from the component understanding, the focal point now shifts to the installation process of a Nitrous Injection Kit. This process encompasses the selection of the appropriate kit, comprehensive steps of setup and installation, and adherence to safety guidelines. The following discussion will elucidate these points, providing a detailed roadmap for automotive enthusiasts and professionals alike.

Choosing the Right Kit

How does one select the appropriate nitrous injection kit and navigate the installation process?

- First, consider the power goals for your vehicle. Select a kit that can deliver the required amount of nitrous to meet these objectives.

- Second, research the compatibility of the kit with your specific model and make of vehicle. Not all kits are universally compatible.

- Third, scrutinize the components of the kit. A high-quality nitrous injection kit should contain a nitrous bottle, solenoids, a nitrous line, and a switch to activate the system.

- Lastly, review the installation instructions. Ensure they are clear, detailed and within your technical proficiency.

Setup and Installation

Both the selection and purchase of a nitrous injection kit are crucial steps, but the true test of success lies in the proper setup and installation of the kit in your vehicle. After obtaining the right kit, the first step towards installation is a thorough inspection of components to ensure no damaged parts have been shipped. The mounting location for the nitrous bottle requires careful selection, ensuring it is secure and oriented correctly, typically at a 15-degree angle. The nitrous line must be meticulously routed away from heat sources and moving parts. The electrical wiring requires precision, connecting the system to a 12-volt power source and grounding appropriately. Finally, the jet sizing for the nitrous and fuel solenoids must be accurately calibrated to achieve optimal performance.

Safety Guidelines Compliance

Adherence to safety guidelines is paramount during the installation process of a nitrous injection kit to prevent potential hazards and ensure optimal performance.

- Always disconnect the battery before starting any installation to avoid electrical mishaps.

- Check the integrity of all components, ensuring no cracks or damage exist that could compromise their function.

- The kit should be installed by a professional or under professional supervision to guarantee correct installation procedures are followed.

- During the installation, ensure adequate ventilation due to the potential release of nitrous oxide, a potentially harmful gas when concentrated.

Safety Measures to Consider When Using Nitrous Injection

Undeniably, prioritizing safety is paramount when utilizing nitrous injection to avoid any potential hazards or mishaps. The power boost from nitrous can be exhilarating, but it also comes with a responsibility to ensure that its use does not compromise safety.

| Safety Measure | Importance |

|---|---|

| Correct Installation | Nitrous systems must be correctly installed to ensure they function properly and safely. This includes proper mounting of the bottle, correct routing of lines, and secure connections. |

| Regular System Checks | Regular inspections of the nitrous system can help detect problems early. Pay attention to the bottle pressure, check for leaks, and ensure that the system is delivering the right amount of nitrous. |

| Safe Storage and Handling | Nitrous oxide is a high-pressure gas. Handle bottles with care, store them in a cool, dry place, and never expose them to open flame or heat sources. |

Maximizing Performance With Nitrous Injection

In maximizing performance with nitrous injection, two primary areas demand our attention: nitrous injection efficiency and performance boosting techniques. By optimizing the efficiency of the nitrous system, we ensure the maximum power output for each nitrous oxide burst. Concurrently, various techniques can be employed to further amplify the overall performance of the vehicle.

Nitrous Injection Efficiency

One must comprehend the intricacies of nitrous injection systems to truly maximize their efficiency and performance. This involves understanding the optimal conditions for nitrous usage, its potential effects on your engine, and how to properly maintain the system for continued efficiency.

The following list breaks down key components for maximizing nitrous injection efficiency:

- Optimal Use Conditions: Nitrous should be used at wide open throttle (WOT) to prevent engine damage.

- Impact on Engine: Nitrous can increase cylinder pressures and temperatures, so it's crucial to monitor these parameters.

- System Maintenance: Regular inspection and maintenance of the nitrous system ensures its longevity and efficiency.

- Tuning: Proper tuning can optimize the nitrous-to-fuel ratio, enhancing power output and efficiency.

Performance Boosting Techniques

While nitrous injection can provide a significant increase in power, it's essential to understand and implement specific techniques to fully maximize its performance potential. The first step is proper system calibration, which involves fine-tuning the nitrous and fuel jets to achieve optimal power output while maintaining engine safety. Additionally, heat management is crucial; using a bottle heater to maintain nitrous at an ideal temperature (around 85 degrees Fahrenheit) can drastically improve its efficacy. A purge valve is also beneficial, clearing the delivery system of gaseous nitrous for a more potent liquid nitrous injection. Lastly, to liberate your engine's full potential, consider a progressive controller for a more controlled nitrous delivery. In the next section, we'll delve into troubleshooting common nitrous injection issues.

Troubleshooting Common Nitrous Injection Issues

Despite the impressive power gains nitrous injection can provide, there are common issues users may encounter that require effective troubleshooting.

- Inconsistent Nitrous Flow: This can be a result of a malfunctioning or improperly installed nitrous solenoid. The solenoid needs to be inspected and replaced if necessary.

- Nitrous Backfire: This occurs when there's a sudden lean condition in the combustion chamber, often caused by a delay in fuel delivery or a malfunctioning spark plug. To remedy this, ensure the fuel system is delivering adequately and spark plugs are in good working condition.

- Poor Performance Despite Nitrous Activation: This is typically caused by a nitrous system that's not properly tuned. It's crucial to tune the nitrous system according to the engine's specifications and operating conditions.

- Premature Nitrous Depletion: This could be due to a leak in the system or excessive usage. Check for leaks regularly and ensure nitrous is used in moderation to avoid premature depletion.

Understanding these common issues can liberate users from the frustration of unanticipated problems, allowing them to fully harness the power of nitrous injection. As always, consult with a professional if you're unsure about any aspect of nitrous system maintenance or troubleshooting.

Frequently Asked Questions

What Is the History and Origin of Nitrous Injection Systems?

Nitrous injection systems originated during World War II for enhancing aircraft performance. Post-war, this technology transitioned to automotive use, providing drivers with instant horsepower boost, revolutionizing motorsport, and empowering drivers with unprecedented vehicle control.

Are There Any Legal Issues or Restrictions Associated With Using Nitrous Injection?

Yes, legal issues with nitrous injection systems exist. Regulations differ by location, with some regions banning their street use due to safety risks. It's crucial for users to understand local laws before installation.

How Does the Use of Nitrous Injection Affect the Vehicle's Fuel Economy?

Nitrous injection, while boosting engine performance, can significantly impact fuel economy. Due to the increased combustion rate, fuel consumption can rise by up to 20%. Thus, it's a trade-off between power and efficiency.

What Are the Environmental Impacts of Using Nitrous Injection in a Vehicle?

The use of nitrous injection in vehicles can lead to increased greenhouse gas emissions due to higher fuel consumption rates, thereby contributing to global warming and other environmental issues.

Can Nitrous Injection Systems Be Used in All Types of Vehicles or Only Specific Models?

As the saying goes, "one size doesn't fit all." Nitrous injection systems can indeed be tailored to a variety of vehicle types, however, not all models are compatible due to differing engine capacities and configurations.

Conclusion

In conclusion, nitrous injection systems provide a significant power boost to automotive engines, allowing for enhanced performance. However, their installation and use require technical expertise and careful attention to safety measures. Irony lies in the fact that this powerful tool, often associated with reckless speed, demands a great deal of precision and caution. Despite potential issues, when used correctly, nitrous injection systems can unlock unparalleled levels of engine power.