Maximizing Cooling System Efficiency: 5 Fan Belt Tips

When it comes to your vehicle's cooling system, think of the fan belt as the conductor of a well-orchestrated symphony. Maintaining its optimal performance is key to ensuring that your engine stays cool and efficient.

But how can you ensure that your fan belt is operating at its best potential? By following these five essential tips, you can proactively enhance your cooling system's efficiency and keep overheating at bay.

Key Takeaways

- Regular inspection for wear and tension ensures efficient cooling system operation.

- Proper alignment and tension prevent premature wear and costly repairs.

- Adhere to manufacturer guidelines for replacement frequency to avoid breakdowns.

- Select durable, compatible materials for optimal fan belt performance and longevity.

Importance of Checking Fan Belt Condition

Regularly inspecting the fan belt's condition is crucial for preventing unexpected failures and costly repairs. Signs of wear such as cracks, fraying, or glazing indicate the need for immediate attention. By incorporating preventative maintenance measures, you can ensure the longevity and efficiency of your cooling system. Detecting these signs early on allows for timely replacement of worn fan belts, preventing potential engine overheating and decreased cooling system efficiency.

To maximize cooling system efficiency, it's essential to conduct routine checks for any irregularities in the fan belt. A damaged fan belt not only compromises the performance of the cooling system but also puts your vehicle at risk of significant damage. By staying proactive and attentive to the condition of the fan belt, you can avoid unexpected breakdowns and costly repairs. Remember, a small investment of time in inspecting the fan belt today can save you from major headaches down the road.

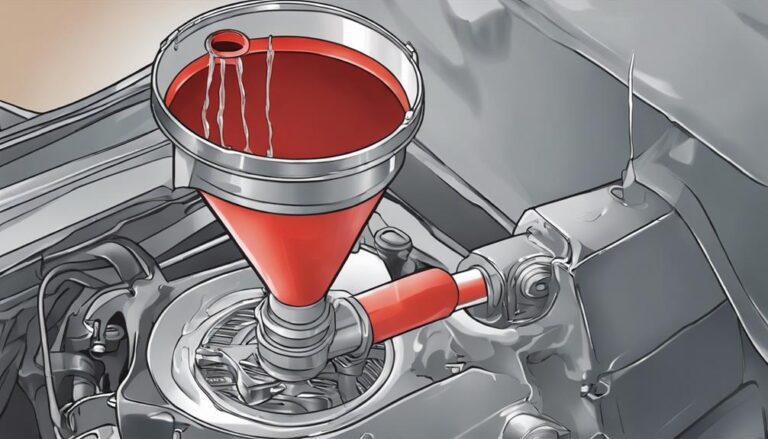

Fan Belt Tension Adjustment

To ensure optimal performance and longevity of your vehicle's cooling system components, precise adjustment of the fan belt tension is essential. When it comes to fan belt tension adjustment, there are key factors to consider:

- Tension Gauge Calibration: Utilizing a tension gauge is crucial for accurately measuring the tension of the fan belt. Ensure that the tension gauge is properly calibrated to provide accurate readings.

- Belt Tensioner Function: Understanding how the belt tensioner functions is vital. The belt tensioner plays a significant role in maintaining the appropriate tension level of the fan belt. Make sure the tensioner is functioning correctly to avoid issues.

- Regular Inspection and Adjustment: Regularly inspecting and adjusting the fan belt tension is necessary to prevent premature wear on pulleys and bearings. This practice ensures that the fan belt operates at the optimal tension level for efficient cooling system performance.

- Consistent Monitoring: Continuously monitor the fan belt tension to guarantee consistent airflow and cooling capacity. Consistent monitoring allows for timely adjustments, preventing inefficiencies in the cooling system operation.

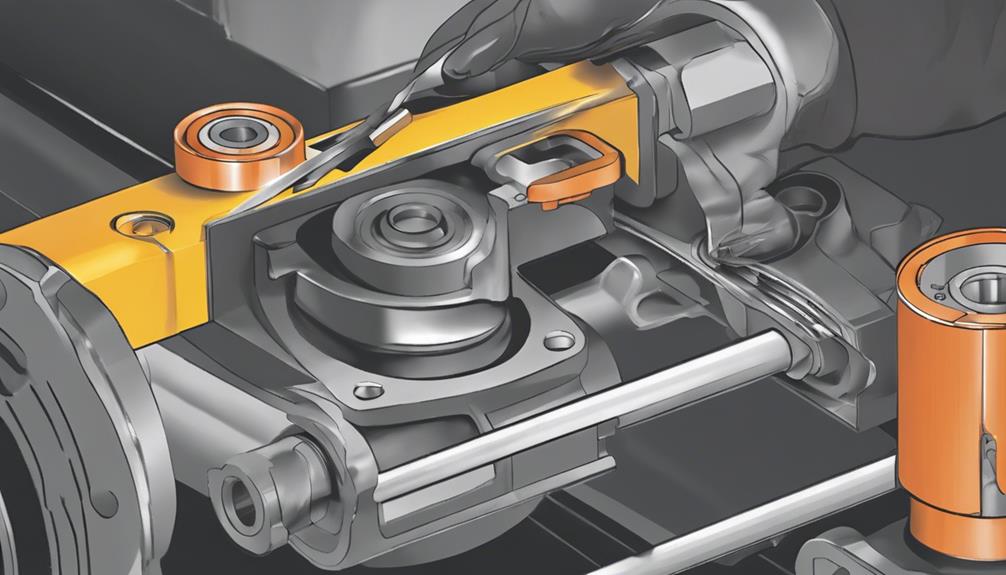

Fan Belt Alignment Inspection

When assessing fan belt alignment as part of your cooling system maintenance routine, ensure that the belt position relative to the pulleys is carefully inspected for proper alignment. Pulley alignment plays a crucial role in the overall efficiency of the cooling system.

Misaligned belts can cause premature wear, reduce the system's effectiveness, and even lead to potential damage. Proper alignment guarantees that the fan belt operates smoothly, minimizing friction and extending its longevity.

During routine maintenance, visually inspecting and adjusting the fan belt alignment can significantly optimize the efficiency of the cooling system. Correct alignment is paramount in maximizing the performance of the cooling system and preventing costly repairs down the line.

Regularly checking and maintaining the alignment of your fan belt is a proactive approach that ensures your cooling system operates at its best, keeping your engine running smoothly and efficiently.

Fan Belt Replacement Frequency

For optimal cooling system performance, adhere to manufacturer guidelines regarding the replacement frequency of fan belts, typically ranging between 60,000 to 100,000 miles based on individual usage and environmental conditions. Following these mileage benchmarks ensures that your cooling system operates at peak efficiency.

Here are some essential points to consider:

- Regular Inspection: Periodically check your fan belts for signs of wear, cracks, or fraying to determine if replacement is necessary.

- Tension Monitoring: Over time, fan belts can lose tension, affecting their ability to drive the cooling system components efficiently.

- Environmental Factors: Environmental conditions such as extreme heat or cold can impact the lifespan of fan belts, necessitating earlier replacement in harsh climates.

- Manufacturer Recommendations: Adhering to the manufacturer's suggested replacement intervals is crucial to prevent overheating, engine damage, and unexpected breakdowns, ultimately ensuring the longevity of your cooling system.

Fan Belt Compatibility With System

Selecting the correct fan belt size, type, and material is essential to ensure optimal compatibility with the cooling system's requirements and specifications for efficient performance. When choosing a fan belt, factors such as material selection and size considerations play a crucial role in the overall effectiveness of the cooling system. The table below outlines key points to consider when evaluating fan belt compatibility with the system:

| Fan Belt Compatibility Factors | Description | Importance |

|---|---|---|

| Material Selection | Choose durable materials like rubber or neoprene for longevity and reliability. | High |

| Size Considerations | Ensure the fan belt fits snugly to prevent slipping and ensure proper operation. | Critical |

| System Requirements | Match the fan belt specifications with the cooling system's needs for optimal performance. | Essential |

| Compatibility Testing | Test the fan belt under various conditions to verify its compatibility and functionality. | Recommended |

Frequently Asked Questions

How Can I Tell if My Fan Belt Is Causing My Engine to Overheat?

If your engine overheats, check the fan belt. Inspect for wear, cracks. A damaged fan belt can cause overheating. Look for fraying, looseness, or squealing noises. Replace as needed to prevent engine damage and maintain optimal performance.

Can Using a Different Brand of Fan Belt Affect the Efficiency of My Cooling System?

Using a different brand of fan belt can impact your cooling system's efficiency. Brand comparison and compatibility checks are crucial for optimal performance. Ensure the belt's specifications match your vehicle's requirements for maximum cooling effectiveness.

Are There Any Warning Signs That Indicate It's Time to Replace My Fan Belt?

If you notice belt wear or hear a squealing noise during operation, it's time to replace your fan belt. Regular visual inspections and adherence to your maintenance schedule are key to avoiding potential cooling system issues.

Will Adjusting the Tension of My Fan Belt Improve the Overall Performance of My Cooling System?

Adjusting the tension of your fan belt can significantly improve the overall performance of your cooling system. Proper maintenance, including ensuring the right tension, enhances efficiency and prevents issues. Regular checks are crucial.

What Are Some Common Mistakes People Make When Inspecting Their Fan Belt Alignment?

When inspecting your fan belt alignment, ensure proper tensioning for efficiency. Watch for belt wear and tear, often overlooked. Misalignment can lead to system failure. Regular checks prevent costly repairs and maintain optimal performance.

Conclusion

In conclusion, by regularly inspecting and maintaining your fan belt, you can significantly enhance the efficiency and performance of your cooling system. Ensure proper tension, alignment, and compatibility to prevent overheating and maximize heat dissipation.

Don't overlook the importance of these simple yet crucial steps in maintaining a well-functioning cooling system. Stay proactive and attentive to detail to keep your system running smoothly and effectively.