Wheel Bearing Vs Hub Assembly: Key Differences Explained

When you hear a strange humming noise coming from your vehicle's wheel, you might wonder if it's a wheel bearing or hub assembly issue. Understanding the nuances between these components is essential for proper maintenance and performance.

By delving into the key differences between wheel bearings and hub assemblies, you can make informed decisions about your vehicle's upkeep and guarantee smooth driving experiences.

Key Takeaways

- Wheel bearings enable wheel rotation with minimal friction, while hub assemblies support hub components and connect to the suspension system.

- Ball bearings in wheel bearings offer smooth operation but may wear faster, while tapered roller bearings in hub assemblies provide durability.

- Regular maintenance is essential for optimal performance and safety of both components, with specific care tailored to wheel bearings and hub assemblies.

- Proper installation and lubrication are crucial for wheel bearings and hub assemblies to ensure longevity and peak functionality.

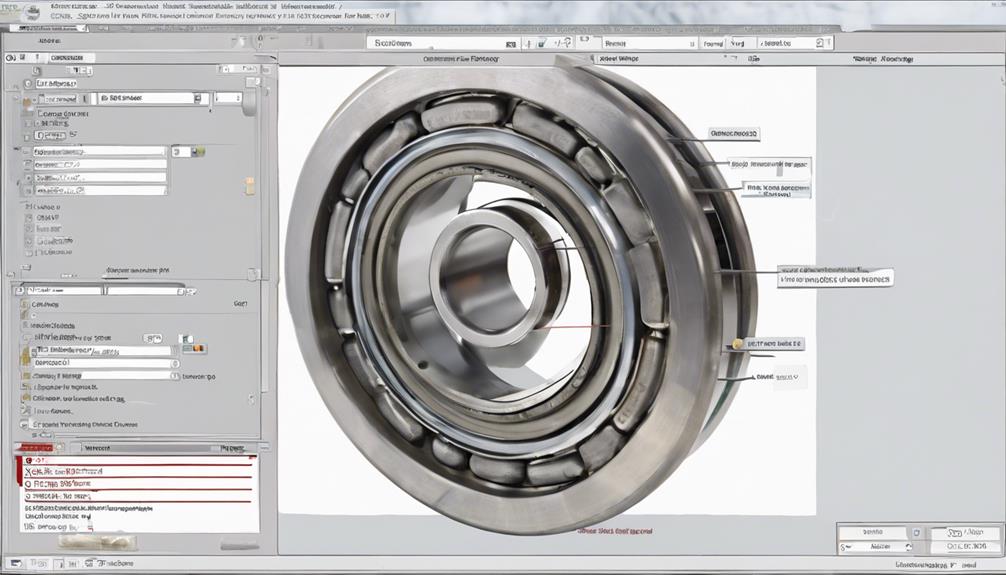

Wheel Bearing Vs. Hub Assembly: Construction Variances

When comparing wheel bearings to hub assemblies, the construction variances play a crucial role in understanding their distinct functions within a vehicle's suspension system. Wheel bearings, typically consisting of ball bearings or rollers encased in a metal ring, bear the weight of the vehicle on the axles and aid in the smooth rotation of the wheel. On the other hand, hub bearings support the hub assembly at the wheel's center and can be constructed using ball bearings or tapered roller bearings.

The primary role of wheel bearings is to enable wheel rotation with minimal friction, essential for efficient vehicle movement. In contrast, hub bearings provide support for various components within the hub assembly, such as the brake system. Wheel bearings are lubricated with grease to reduce friction, ensuring smooth operation, while hub bearings may use grease or oil depending on their design specifications. These construction variances have a significant impact on the durability and specific functions of wheel bearings and hub assemblies within the vehicle's suspension system.

Material Differences in Wheel Bearings Vs. Hub Assemblies

Analyze the material disparities between wheel bearings and hub assemblies to comprehend their distinct roles in the wheel and axle system.

Wheel bearings, typically made of ball bearings or rollers encased in a metal ring, support the vehicle's weight on the axles.

In contrast, hub assemblies consist of the hub that connects the wheel to the axle, incorporating wheel bearings and studs for vehicle attachment.

The material composition discrepancies between wheel bearings and hub assemblies are rooted in their specific functions within the vehicle suspension system.

Wheel bearings facilitate wheel movement by rotating with the axle, while hub assemblies provide structural support to the hub and wheel components without rotational capabilities.

Recognizing these material variances is essential for proper maintenance and replacement tasks in the vehicle's suspension system, ensuring the most important functionality and safety on the road.

Understanding the distinct materials utilized in wheel bearings and hub assemblies enhances your comprehension of their critical roles in the overall wheel and axle assembly.

Performance Variances in Wheel Bearings Vs. Hub Assemblies

Performance distinctions between wheel bearings and hub assemblies can greatly impact the overall functionality and safety of a vehicle's suspension system. Wheel bearings, typically made of ball bearings or tapered roller bearings, support the vehicle's weight on axles and enable wheel rotation with minimal friction. In contrast, hub assemblies support hub components in the wheel center and connect to the suspension system, ensuring proper alignment and wheel operation.

The choice between ball bearings and tapered roller bearings affects the performance of wheel bearings and hub assemblies. Ball bearings offer smooth operation but are more susceptible to wear and tear due to constant rotation. On the other hand, tapered roller bearings provide increased durability and load-bearing capacity, enhancing the longevity and reliability of the hub assembly.

Regular maintenance and timely replacement of wheel bearings and hub assemblies are essential to assure peak performance and safety. Neglecting these components can lead to issues such as increased friction, alignment problems, and even wheel detachment, underscoring the importance of proactive care in maintaining a vehicle's suspension system.

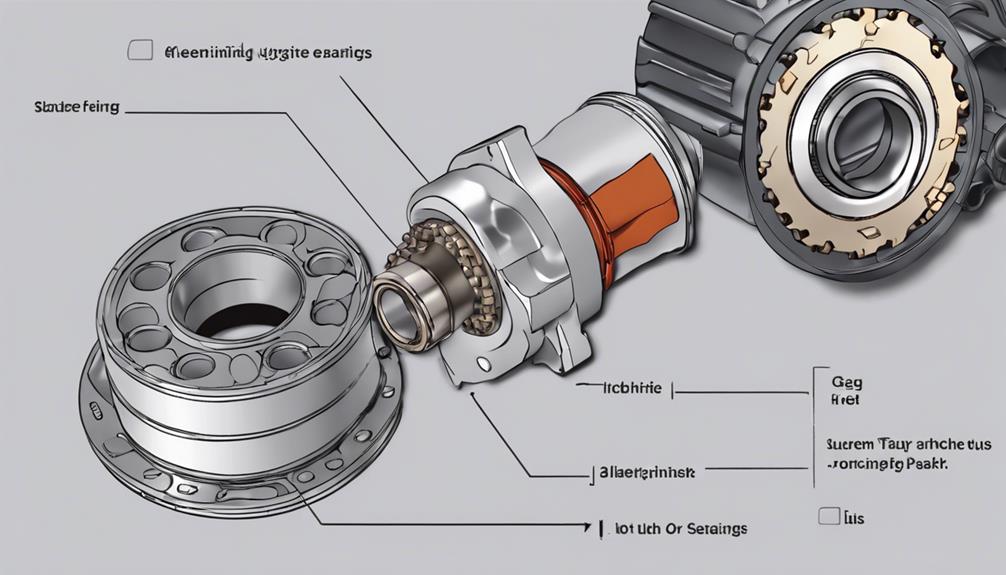

Installation Variances: Wheel Bearings Vs. Hub Assemblies

To understand the differences in installation between wheel bearings and hub assemblies, it's important to recognize their distinct placements and functions within a vehicle's suspension system.

Wheel bearings are directly installed on the vehicle's axles, supporting the weight of the vehicle and allowing the wheels to rotate smoothly around them. On the other hand, hub assemblies are positioned at the center of the wheels and don't rotate with the axles like wheel bearings.

When it comes to lubrication, wheel bearings are typically greased, while hub assemblies may use grease or oil for lubrication purposes. Due to their location and function, wheel bearings are more susceptible to wear and tear compared to hub assemblies.

Proper installation of both wheel bearings and hub assemblies is essential for ensuring excellent vehicle safety and performance. When considering replacement parts, understanding the installation variances between wheel bearings and hub assemblies is key to maintaining a vehicle's suspension system effectively.

Maintenance Variances: Wheel Bearings Vs. Hub Assemblies

Regular maintenance for wheel bearings and hub assemblies is essential to guarantee peak performance and longevity of these important components in a vehicle's suspension system. When comparing the maintenance requirements of wheel bearings and hub assemblies, it is critical to understand the specific needs of each to make sure maximum functioning and safety of your vehicle. Wheel bearings necessitate regular greasing to prevent wear and make sure smooth rotation, while hub assemblies, which consist of various components like sensors and seals, require specialized maintenance procedures. Neglecting proper maintenance of wheel bearings can result in premature failure and impact vehicle handling, whereas hub assemblies, playing a critical role in supporting the wheel structure, need meticulous inspection for peak performance. By comprehending and addressing the distinct maintenance variances between wheel bearings and hub assemblies, you can significantly extend their lifespan and enhance overall vehicle safety.

| Bearings Maintenance | Hub Assemblies Maintenance |

|---|---|

| Regular greasing needed | Specialized procedures required |

| Prevents wear and ensures smooth rotation | Consists of multiple components like sensors and seals |

| Neglect can lead to premature failure | Important for supporting the wheel structure |

| Impact on vehicle handling | Requires careful inspection for maximum performance |

Frequently Asked Questions

What Is the Difference Between Wheel Bearing and Hub Assembly?

When differentiating between wheel bearings and hub assemblies, remember that wheel bearings require regular maintenance for best performance and have a shorter lifespan compared to hub assemblies. Hub replacements are essential for maintaining wheel stability and overall performance.

Can I Just Replace the Wheel Bearing and Not the Hub?

You can replace just the wheel bearing, but consider bearing compatibility and hub wear. DIY replacement may save money, but replacing the entire hub assembly is recommended for long-term reliability. Seek mechanic advice for the best solution.

What Is a Basic Component in a Driving Hub and Wheel Bearing Assembly?

In a driving hub and wheel bearing assembly, a basic component is the bearing, supporting vehicle weight. Wheel bearings on axles rotate with them, needing grease lubrication. Hub bearings in the wheel center support hub components, needing grease or oil lubrication.

Does the Wheel Hub Contain the Bearing?

Yes, the wheel hub contains the bearing. It serves as the bearing housing, connecting the wheel to the axle. The wheel spindle secures everything in place, with the axle nut, bearing race, and wheel flange contributing to the assembly's functionality and stability.

Conclusion

After examining the construction, material, performance, installation, and maintenance variances between wheel bearings and hub assemblies, it's clear that each component plays an important role in the overall functionality of a vehicle's wheel system. Understanding the differences and properly maintaining these components is essential for ensuring safety and best performance on the road.

Remember, neglecting these key components could result in costly repairs and potential safety hazards. Stay informed and proactive for a smoother ride.