10 Best Solutions for Fixing Water Pump Issues

When it comes to addressing water pump issues, think of yourself as a diligent detective unraveling the mysteries of a malfunctioning mechanism. From uncovering the root cause of low water pressure to silencing the clamor of a noisy pump, the journey to resolving these problems is both challenging and rewarding.

By exploring the ten best solutions that can breathe new life into your water pump, you'll equip yourself with the knowledge needed to tackle these issues head-on.

Key Takeaways

- Early detection of water pump issues through inspection and maintenance is crucial.

- Proper sizing, alignment, and regular checks can prevent costly pump failures.

- Timely repair of leak sources like gaskets and seals is essential for engine health.

- Utilize expert advice and resources for effective troubleshooting and resolution of water pump problems.

Identifying Overheating Symptoms

If you notice your engine overheating, pay attention to common symptoms like coolant leakage around the water pump's weep holes. This can indicate potential water pump issues that may lead to further damage if not addressed promptly. To prevent overheating, it's essential to implement effective strategies such as regular coolant checks and maintaining proper coolant levels.

Temperature monitoring techniques play a crucial role in identifying early signs of overheating. Keep an eye on your temperature gauge while driving to ensure it stays within the normal operating range. Unusual noises coming from the water pump during engine operation can also be a warning sign of potential overheating problems. Address any strange sounds promptly to prevent further issues.

Detecting Water Leakage Sources

When inspecting your water pump for leakage sources, it's crucial to focus on common spots like gaskets, seals, and the pump housing.

Look for water leaks around the pump shaft to pinpoint seal issues, while leaks from the casing often indicate gasket failure.

To address these leaks effectively, identifying the source accurately is key to implementing the necessary repairs promptly.

Common Leakage Spots

To effectively detect water leakage sources in water pumps, scrutinize gaskets, seals, pump shaft areas, housing integrity, and installation quality for any potential issues. When inspecting these areas, keep in mind the following tips:

- Gasket Maintenance Tips: Check gaskets regularly for wear and tear, and replace them if necessary to maintain a proper seal.

- Seal Replacement Techniques: If you notice seal issues around the pump shaft, follow proper replacement procedures to ensure a secure seal.

- Housing Integrity: Look for cracks or damage in the pump housing that could be causing leaks, and address them promptly.

- Installation Quality: Ensure that the pump is installed correctly to prevent any leaks due to improper fitting or connections.

Inspection Techniques

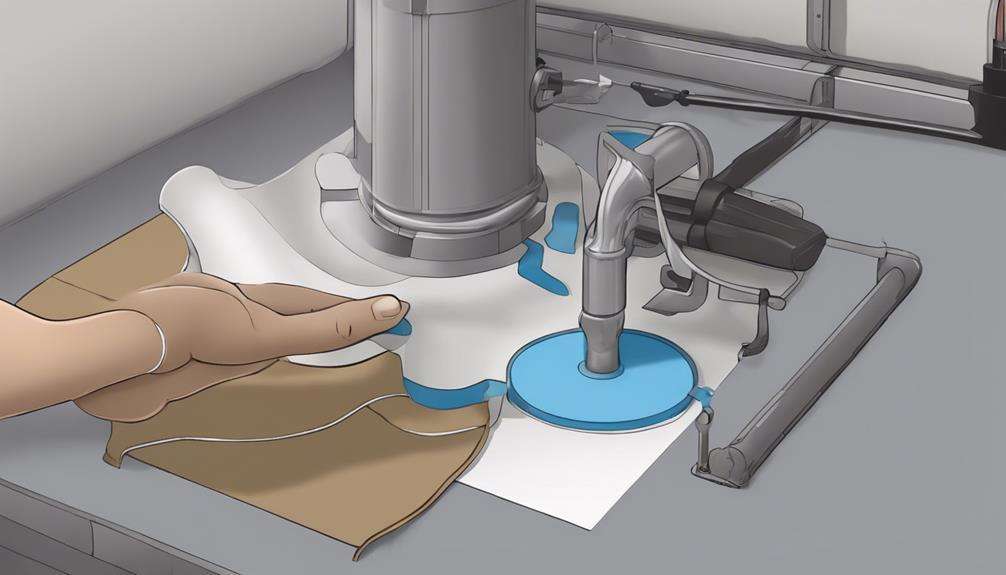

Inspecting gaskets, seals, and pump shaft areas is crucial for detecting water leakage sources in water pumps. To troubleshoot leaks effectively, check for signs of moisture, puddles, or wet spots around the pump.

Additionally, inspect the pump housing for corrosion or rust, which could indicate potential leakage issues. Pay close attention to the weep holes near the pump for any coolant seepage, a clear sign of a leak.

For more precise leak detection methods, consider using dye or UV light tests to pinpoint the exact location of the leaks. These maintenance tips will help you identify and address water pump leaks promptly, setting the stage for efficient repair techniques.

Repairing Leak Sources

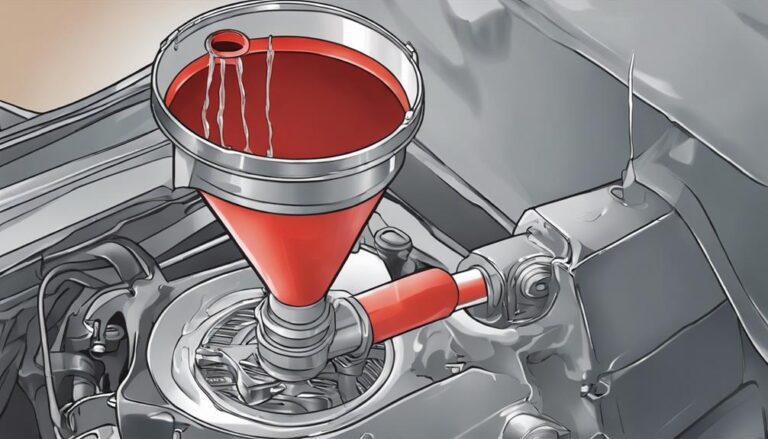

To address water pump leaks effectively, start by thoroughly examining the gasket, pump shaft seals, and housing for any signs of water seepage. When detecting water leakage sources, consider the following:

- Look for cracks in the pump housing and corrosion as potential sources of leaks.

- Inspect connections and fittings for loose or damaged components contributing to leaks.

- Address improper installation issues that may lead to water pump leaks.

- Prevent leaks through regular maintenance, including replacing worn-out seals and gaskets.

For sealing techniques and maintenance tips, consider DIY fixes for minor leaks, but don't hesitate to seek professional help for complex issues.

Addressing Low Water Pressure Problems

If you're facing low water pressure, adjusting the pressure regulator and inspecting for pipe blockages are key initial steps.

Clogged impellers, incorrect pump size, and airlocks could be culprits for the reduced pressure you're experiencing.

To ensure optimal pump performance, addressing these issues promptly is crucial.

Pressure Regulator Adjustment

Optimizing the performance of your water pump starts with adjusting the pressure regulator to ensure correct pressure settings. Here are four essential steps for adjusting the pressure regulator to address low water pressure effectively:

- Check Pressure Gauge Calibration: Verify the accuracy of the pressure gauge to ensure precise pressure readings.

- Analyze Water Quality: Poor water quality can affect pressure regulator performance; assess and improve water quality as needed.

- Adjust Pressure Regulator: Use the pressure regulator settings to increase or decrease pressure levels for optimal water flow.

- Regular Maintenance: Regularly inspect and adjust the pressure regulator to maintain consistent and adequate water pressure in the system.

Pipe Blockage Inspection

Inspecting your pipes for debris or mineral buildup is crucial in addressing low water pressure problems efficiently. To prevent pipe blockages that lead to low water pressure, consider implementing regular maintenance involving pipe inspection. By troubleshooting pipe blockages early on, you can avoid decreased water flow and pressure issues.

Maintenance tips such as installing filters in the system can help prevent debris from causing blockages. Additionally, conducting thorough inspections using appropriate inspection methods can help identify any potential blockages affecting water pressure.

Addressing pipe blockages promptly is key to improving water flow and increasing overall water pressure in your system. Stay proactive in your pipe blockage prevention efforts to ensure optimal water pressure at all times.

Quieting Noisy Water Pump Operation

To address noisy water pump operation, begin by bleeding the system to eliminate air causing vibrations and noise. Here are some practical steps to help you quiet down your water pump:

- Check for Air: Bleeding the system will remove air pockets that cause vibrations and noise.

- Tighten Components: Ensure all parts are securely fastened to reduce rattling noises.

- Maintenance for Cavitation: Proper maintenance will help eliminate cavitation issues, which can contribute to noise.

- Inspect Bearings: Regularly check and replace worn bearings to prevent noisy pump operation.

Resolving Cavitation Issues

When dealing with water pump cavitation, it's essential to understand the causes and prevention techniques to maintain the pump's efficiency.

Properly priming the pump to remove air pockets and adjusting suction conditions can help prevent cavitation issues.

Regular maintenance, such as checking for leaks and blockages, is crucial in avoiding cavitation and ensuring optimal pump performance.

Cavitation Causes

Cavitation causes damage and noise in water pumps when low pressure leads to water vaporization and bubble formation. To address cavitation issues effectively, consider the following troubleshooting techniques:

- Maintain Proper Water Flow: Ensure consistent water flow to prevent the formation of low-pressure zones that trigger cavitation.

- Install a Pressure Regulator: Utilize a pressure regulator to stabilize pressure levels and alleviate the risk of cavitation.

- Increase Pump Capacity: Enhance the pump's capacity to handle water flow demands, reducing the likelihood of cavitation occurrence.

- Regular Inspection and Maintenance: Routinely inspect and maintain pump components such as impeller blades, inlet, and outlet systems to prevent cavitation, thus maintaining optimal pump performance.

Prevention Techniques

If you want to prevent water pump cavitation issues effectively, focus on maintaining proper pump sizing to ensure adequate pressure levels for optimal performance. Regular pump maintenance is crucial in preventing damage caused by cavitation. Here are some practical prevention techniques to keep your water pump running smoothly:

| Prevention Techniques | Description |

|---|---|

| Proper Pump Sizing | Ensure the pump is correctly sized for the application to maintain adequate pressure levels and prevent cavitation. |

| Regular Inspections | Inspect and maintain the impeller regularly to prevent cavitation and ensure optimal pump performance. |

| Component Alignment | Properly align pump components to promote a smooth flow of water, reducing the risk of cavitation. |

| Addressing Air Leaks | Check for air leaks in the system and maintain proper water levels to prevent cavitation issues. |

Understanding Water Pump Failure Signs

A common indicator that your water pump may be failing is coolant leakage around the water pump through visible weep holes. Early detection is crucial for preventing further damage to your vehicle. Here are some signs to look out for:

- Coolant Leakage: Check for any coolant leaks around the water pump. If you notice coolant seeping through the weep holes, it could be a sign of a failing water pump.

- Unusual Noise: Listen for any strange noises coming from the water pump while the engine is running. Unusual sounds could indicate underlying issues that need to be addressed promptly.

- Engine Overheating: If your engine is consistently running hotter than normal, it could be a symptom of water pump failure. Monitor your temperature gauge regularly.

- Puddles Under the Car: Keep an eye out for puddles forming under your vehicle. Water pump leaks can cause coolant to drip onto the ground, signaling a problem that requires immediate attention.

Being aware of these signs and addressing them promptly can save you from costly repairs down the line.

Assessing Repair Costs for Water Pumps

Considering the potential range of costs involved, it's important to understand the factors influencing the repair expenses for water pump replacement. Water pump replacement costs typically range from $50 to $75 on average. However, additional labor charges can significantly impact the total repair cost.

In some cases, water pump replacement jobs may escalate to around $500, depending on the car model and the garage selected for the service. To manage costs effectively, engaging in cost comparison by obtaining multiple quotes from local mechanics is recommended. This practice ensures a competitive price for water pump replacement, allowing you to make an informed decision that aligns with your budget considerations.

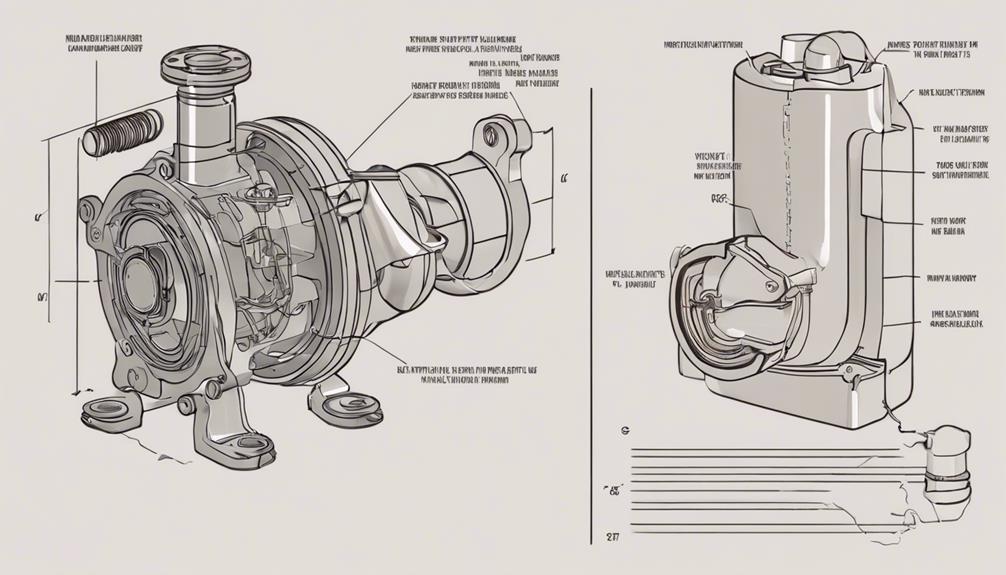

Explaining Water Pump Functionality

How does the water pump function to prevent engine overheating? The water pump ensures your engine stays at the right temperature by circulating coolant throughout the system. Here's a breakdown of its functionality:

- Coolant Circulation: The water pump pushes coolant through the engine to absorb heat and then to the radiator for cooling before returning to the engine. This continuous cycle helps maintain the engine's temperature within the optimal range.

- Impeller Operation: An impeller inside the water pump is vital for its function. Driven by a belt connected to the crankshaft, the impeller creates centrifugal force to move the coolant effectively through the engine.

- Cooling Efficiency: Proper water pump function is crucial for cooling efficiency. Any issues with the pump can lead to inadequate cooling, resulting in potential engine overheating problems.

- Maintenance: Regular maintenance, including checking the impeller for wear and tear, is essential to ensure the water pump operates smoothly and helps prevent costly engine damage from overheating.

Preventing Engine Damage From Water Pump Issues

To prevent engine damage from water pump issues, ensuring timely detection and maintenance is crucial to avoid costly repairs and maintain optimal vehicle performance. Implementing preventive maintenance on your vehicle's water pump is key to engine protection.

Regularly inspect the water pump for any signs of leakage, unusual noises, or decreased coolant levels. Coolant leakage from a failing water pump can lead to engine overheating, which in turn can cause cylinder head damage and decreased performance. Ignoring these issues can result in overheating, causing engine components to warp or fail.

By proactively addressing water pump issues, you can prevent such damage and prolong your vehicle's lifespan. Proper maintenance not only safeguards your engine but also ensures that your vehicle operates at its best. Remember, a well-maintained water pump contributes to the overall health and performance of your engine.

Prioritize preventive maintenance to keep your engine running smoothly and efficiently.

Seeking Expert Advice for Water Pump Troubleshooting

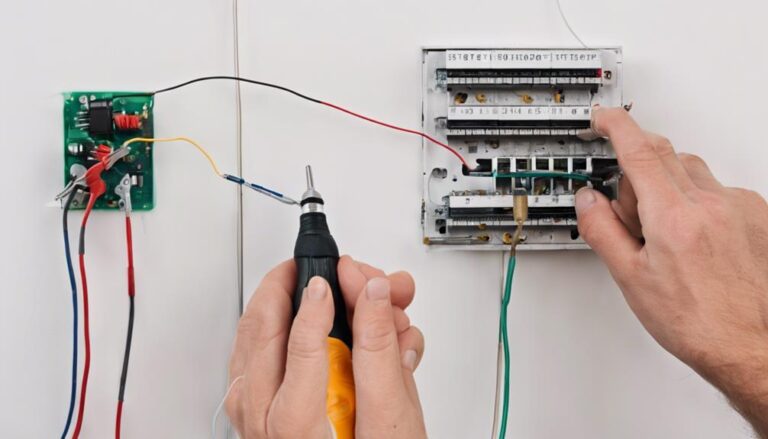

For expert advice on troubleshooting water pump issues, contact our corporate headquarters in Hialeah, FL. Our team of professionals is ready to assist you in resolving any water pump concerns you may have.

Here are some ways to seek expert guidance and apply effective troubleshooting techniques:

- Email Support: Send an email to customerservice@pdwatersystems.com for personalized assistance tailored to your specific water pump issues.

- Phone Consultation: Dial our phone number (954) 474.9090 to speak directly with knowledgeable professionals who can provide immediate guidance on troubleshooting your water pump.

- Online Resources: Explore our website for legal information that offers valuable insights into water pump troubleshooting procedures.

- Manuals and Service Centers: Refer to our service centers, distributors, and manuals for detailed step-by-step guidance on effective water pump troubleshooting techniques.

Frequently Asked Questions

How Do You Fix a Bad Water Pump?

To fix a bad water pump, you can replace it or try troubleshooting tips. Regular water pump maintenance and DIY repairs can prevent issues. Consider using K-Seal for a quick fix on leaks.

What Is the Most Common Problem of Water Pump?

When it comes to water pumps, the most common issue you'll encounter is low water pressure. This can be caused by various factors, so regular pump maintenance and water pump troubleshooting are crucial for smooth operation.

How Do I Get My Water Pump to Work Again?

To get your water pump working again, troubleshoot by checking power sources, testing the pressure switch, fixing leaks, inspecting the motor, and priming for optimal flow. Regular maintenance ensures efficiency and longevity.

Can Water Pumps Be Fixed?

You can definitely fix water pumps by addressing common issues like leaks, low pressure, noise, and starting problems. Regular maintenance, spotting signs of failure early, and DIY repairs can keep your pump running smoothly and prevent costly repairs.

Conclusion

So there you have it, folks! Just remember, when your water pump starts acting up, don't panic – just follow these simple solutions and you'll be back to smooth sailing in no time.

And if all else fails, well, you could always try the ancient technique of sacrificing a chicken to appease the water pump gods. Hey, desperate times call for desperate measures, right?

Happy pumping!