Troubleshooting Techniques of Trailer Brake Controller: Mastering the Art of Repair

To troubleshoot trailer brake controllers, follow these techniques: check for power supply, ensure connection with the tow vehicle, inspect brake magnets and ground wires, and test the brake controller settings. By addressing these factors, you can identify and fix potential issues with the trailer brake controller, ensuring its effective operation during towing.

Credit: www.amazon.com

Understanding The Basics

The Function Of A Trailer Brake Controller

A trailer brake controller plays a crucial role in ensuring the safety and control of your trailer while braking. It works by sending signals to the trailer’s brakes, enabling them to activate and slow down in sync with your vehicle.

Understanding the basics of how a trailer brake controller functions is essential for troubleshooting any issues that may arise. Here are the key points to consider:

- Proportional control: A trailer brake controller adjusts the braking power based on how much force is being applied to the tow vehicle’s brakes. This proportional control allows for smoother and more efficient braking, reducing the risk of skidding or jackknifing.

- Manual control: In addition to the proportional control, many trailer brake controllers feature a manual override. This allows you to manually apply the trailer brakes independently of the tow vehicle’s brakes, offering extra braking power when needed, such as during downhill descents or emergency situations.

- Brake signal detection: The brake controller utilizes signals from the tow vehicle’s braking system to activate the trailer’s brakes. It monitors the brake pedal position, vehicle deceleration, and brake light activation to determine when and how much braking force to apply to the trailer.

- Electric connection: The trailer brake controller is electrically connected to both the tow vehicle and the trailer’s braking system. This connection enables the controller to relay the braking signals effectively, ensuring the trailer’s brakes engage at the appropriate intensity.

- Adjustable settings: Depending on the trailer’s weight and brake system, the trailer brake controller allows you to adjust various settings. These settings typically include sensitivity, gain, and maximum braking force, allowing you to fine-tune the trailer’s braking performance according to your specific towing needs.

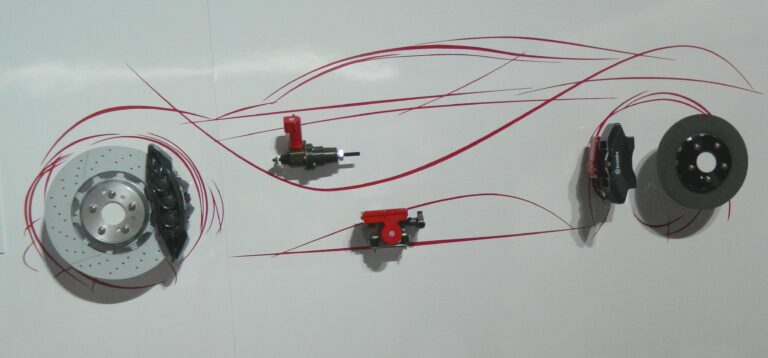

Components Of A Trailer Brake System

A trailer brake system involves several components working together to ensure effective braking. Understanding these components is essential for troubleshooting any brake-related issues. Here are the key points:

- Brake controller: As discussed earlier, the trailer brake controller is the central component that regulates the braking force of the trailer. It is usually mounted inside the tow vehicle, within easy reach of the driver.

- Brake pedal switch: The brake pedal switch is located in the tow vehicle and sends a signal to the trailer brake controller, indicating when the driver is applying the brakes.

- Wiring harness: A wiring harness connects the trailer brake controller to the tow vehicle’s electrical system. It allows the transfer of signals between the two, enabling seamless communication for effective braking.

- Trailer brakes: The trailer’s braking system includes brake assemblies, brake shoes or pads, and drums or rotors. When activated by the trailer brake controller, the trailer brakes engage, providing the necessary stopping power.

- Breakaway system: A breakaway system is a safety feature required on trailers. It automatically activates the trailer brakes if the trailer becomes separated from the tow vehicle, preventing it from rolling away uncontrollably.

Importance Of A Properly Functioning Brake Controller

Ensuring that your trailer brake controller is in proper working condition is crucial for safe towing. Here’s why it matters:

- Control and stability: A properly functioning brake controller allows you to maintain control and stability while towing. It ensures that the trailer’s brakes engage in a synchronized manner with the tow vehicle, preventing the trailer from pushing or swaying excessively.

- Reduced braking distance: An efficient brake controller helps reduce the braking distance, allowing you to stop your tow vehicle and trailer more quickly and safely.

- Enhanced safety: A properly functioning brake controller significantly improves overall safety by minimizing the risk of accidents, such as jackknifing or skidding. It ensures that the trailer’s brakes respond appropriately in various driving conditions, providing greater peace of mind during your towing adventures.

- Compliance with regulations: Many countries have specific regulations regarding trailer brakes and brake controllers. Ensuring that your brake controller is in proper working order helps you comply with these regulations, avoiding potential fines or legal issues.

- Preventative maintenance: Regularly checking and maintaining your brake controller helps identify any potential issues before they become major problems. This proactive approach ensures that your trailer’s braking system remains in optimal condition, reducing the risk of unexpected brake failure.

Understanding the basics of a trailer brake controller, along with the components of a trailer brake system, is crucial for troubleshooting any potential issues. A properly functioning brake controller ensures control, stability, and enhanced safety while towing, making it a vital component of your trailer setup.

Regular maintenance and adherence to regulations will help ensure that your brake controller performs optimally, providing a smooth and secure towing experience.

Common Issues And Their Diagnosis

No power to the brake controller:

- If there is no power to the brake controller, it can lead to ineffective braking. Here are some steps to diagnose the issue:

- Check the power connection: Ensure that the power wire is securely connected to a reliable power source, such as the vehicle’s battery.

- Inspect the fuse: If the brake controller’s fuse is blown, it may result in no power. Replace the fuse if necessary.

- Test the voltage: Use a multimeter to check if there is a proper voltage output from the power source to the brake controller.

Checking the trailer’s battery connection:

- The trailer’s battery connection plays a crucial role in the functioning of the brake system. Consider the following:

- Examine the battery terminals: Ensure that the battery terminals are clean and free from corrosion. Clean them if necessary.

- Check the battery charge: A low battery charge can affect the brake controller’s performance. Charge the trailer’s battery to the recommended level.

Inspecting the wiring and fuses:

- Faulty wiring or blown fuses can disrupt the brake controller’s operation. Here are some steps to analyze this issue:

- Examine the wiring connections: Inspect the wiring harness for any loose or damaged connections. Repair or replace as needed.

- Check the ground connection: Ensure that the brake controller’s ground wire is securely grounded to a suitable surface on the vehicle.

- Inspect the fuses: Check the fuses related to the brake controller for any signs of damage or being blown. Replace if necessary.

Uneven braking:

- Uneven braking can be dangerous and may indicate a problem with the brake controller. Consider the following factors:

- Inspect the brake adjustment: Ensure that the trailer’s brakes are properly adjusted and aligned. Consult the trailer’s manual for instructions.

- Check the brake pads: Worn-out brake pads can cause uneven braking. Replace the brake pads if they are worn or damaged.

Checking for faulty brake magnets:

- Brake magnets are essential components of the trailer’s braking system. Here’s what you can do to troubleshoot this issue:

- Inspect the brake magnets: Check if the brake magnets are worn, damaged, or contaminated. Replace them if necessary.

- Test the magnet’s resistance: Use a multimeter to measure the resistance of the brake magnets. Compare the values to the manufacturer’s specifications.

Adjusting brake balance and proportioning:

- Incorrect brake balance and proportioning can lead to inadequate braking performance. Consider the following steps:

- Adjust the brake balance: Consult the trailer’s manual to find the appropriate brake balance adjustment mechanism. Make the necessary adjustments.

- Check the brake proportioning valve: If your trailer has a brake proportioning valve, ensure it is functioning correctly and not stuck.

Delayed or inconsistent braking:

- Delayed or inconsistent braking can be concerning. Here are some troubleshooting steps to address this issue:

- Inspect the brake fluid: Check the brake fluid level and look for any signs of contamination. Top up or replace the brake fluid if necessary.

- Bleed the brake system: Properly bleeding the brake system can help improve braking response and consistency.

Testing and calibrating the brake controller:

- Proper testing and calibration of the brake controller are essential for optimal performance. Follow these steps:

- Perform a brake test: Test the brake controller by applying the brakes gradually and ensuring the trailer brakes engage smoothly.

- Calibrate the brake controller: If your brake controller has calibration settings, follow the manufacturer’s instructions to adjust them based on your trailer’s weight and braking requirements.

Brake controller error codes:

- Brake controllers may generate error codes to indicate specific issues. Understanding these codes is crucial for effective troubleshooting. Consider the following:

- Interpret the error codes: Refer to the brake controller’s manual or manufacturer’s website to decode the specific error messages and their meanings.

- Follow the troubleshooting steps: Based on the error codes, follow the recommended troubleshooting steps provided by the manufacturer to resolve the issues.

Understanding error messages and their meanings:

- Error messages on the brake controller’s display can provide valuable insights into potential problems. Here’s what you should do:

- Read the error messages: Pay attention to the error messages displayed on the brake controller’s screen.

- Consult the manual: Refer to the brake controller’s manual to understand the meanings and suggested actions for each error message.

Troubleshooting error codes and resolving issues:

- Resolving error codes requires systematic troubleshooting. Follow these steps for effective resolution:

- Identify the error code: Determine the specific error code being displayed on the brake controller.

- Consult the manual or manufacturer: Use the provided information to troubleshoot and resolve the issue. If necessary, reach out to the brake controller’s manufacturer for further assistance.

Tools And Equipment For Brake Controller Repair

Essential Tools For Troubleshooting

Having the right tools is crucial when it comes to troubleshooting and repairing a trailer brake controller. Here are some essential tools you should have in your arsenal:

- Voltage meters and multimeters: These devices are essential for measuring the electrical voltage in your brake controller system. They help you diagnose issues related to voltage fluctuations or malfunctions. With a voltage meter or multimeter, you can accurately identify problems and take the necessary steps to fix them.

- Diagnostic code readers: Brake controllers often come equipped with diagnostic capabilities that provide error codes when a problem occurs. Diagnostic code readers allow you to read these codes, providing valuable information about the underlying issues. By understanding the codes, you can pinpoint the problem more effectively and save time during troubleshooting.

- Replacement parts for brake controller repair: In some cases, troubleshooting may reveal that certain components of your brake controller need to be replaced. It’s important to have a supply of replacement parts on hand, including connectors, wires, sensors, and other essential components. This ensures that you can quickly fix any faulty parts and restore the functionality of your brake controller.

Having the right tools is essential for effective troubleshooting and repair of a trailer brake controller. Voltage meters and multimeters enable accurate voltage measurements, while diagnostic code readers provide valuable insights by decoding error codes. Additionally, having replacement parts readily available allows for swift repairs when components need to be replaced.

Always make sure to have these essential tools at your disposal to effectively troubleshoot and repair your trailer brake controller system.

Step-By-Step Troubleshooting Guide

If you’re experiencing issues with your trailer brake controller, it’s important to follow a step-by-step troubleshooting guide to pinpoint and fix the problem. Here’s a breakdown of the key steps you can take:

Checking For Loose Connections And Corroded Wires

- Inspect all connections between the brake controller and the trailer for any signs of looseness.

- Look for corroded wires or connectors that may be causing an unreliable connection.

- Ensure that all connections are secure and free of any corrosion.

Verifying Proper Trailer Wiring

- Check the trailer wiring to ensure it is installed correctly and functioning properly.

- Look for any loose or damaged wires that may be disrupting the brake controller’s signal.

- Ensure that the trailer wiring matches the wiring requirements of the brake controller.

Performing A Manual Override Test

- Activate the manual override on the brake controller to test if the trailer brakes engage.

- If the brakes do not respond, there may be an issue with the brake controller or the trailer’s wiring.

- Consult the brake controller’s manual for instructions on how to perform the manual override test.

Checking Brake Voltage Output

- Use a multimeter to measure the voltage output of the brake controller.

- Compare the measured voltage to the specifications provided by the manufacturer.

- If the brake voltage output is lower than expected, there may be an issue with the brake controller or the electrical system.

Inspecting The Magnets For Wear And Tear

- Remove the trailer’s drum brakes and inspect the magnets for any signs of wear or damage.

- Look for uneven wear patterns, cracks, or loose connections on the magnets.

- Replace any damaged magnets to ensure proper braking performance.

Testing Magnetic Force And Current

- Use a specialized tool to measure the magnetic force of the trailer’s brakes.

- Compare the measured force to the specifications provided by the manufacturer.

- Additionally, check the current flowing through the magnets to ensure it is within the recommended range.

Understanding Brake Balance And Adjusting Properly

- Ensure that the trailer’s brakes are properly balanced to provide efficient stopping power.

- Adjust the brake balance by following the instructions provided by the brake controller’s manufacturer.

- Improper brake balance can lead to excessive wear or insufficient braking performance.

Calibrating The Proportioning Valve

- Check if the brake controller is equipped with a proportioning valve.

- Follow the manufacturer’s instructions to calibrate the valve for optimal brake performance.

- A properly calibrated proportioning valve helps maintain consistent brake pressure on all wheels.

Checking Reservoir Levels And Replenishing If Necessary

- Inspect the brake fluid reservoir to ensure it is at the recommended level.

- Top off the reservoir if needed using the appropriate type of brake fluid.

- Low brake fluid levels can result in reduced braking effectiveness.

Detecting Contamination Or Air In The Brake Lines

- Inspect the brake lines for any signs of contamination, such as dirt or debris.

- Look for air bubbles in the brake lines, which can affect braking performance.

- If necessary, bleed the brake lines to remove any air or contaminants.

By following this step-by-step troubleshooting guide, you can address and resolve issues with your trailer brake controller, ensuring safe and reliable braking while towing your trailer.

Preventive Maintenance Tips

Regular inspections and maintenance schedule:

- Conduct regular inspections of your trailer brake controller to ensure it is functioning properly.

- Check for any signs of wear, damage, or loose connections.

- Inspect the brake system for any leaks or corrosion.

Cleaning and protecting wiring connections:

- Keep the wiring connections clean and free from dirt, debris, and moisture.

- Use a soft brush or compressed air to remove any dirt or debris from the connections.

- Apply dielectric grease to the connections to protect them from moisture and corrosion.

Lubricating moving parts of the brake system:

- Regularly lubricate the moving parts of the brake system to ensure smooth operation.

- Apply a small amount of lubricant to hinges, pivots, and sliding components.

- Avoid using excessive amounts of lubricant, as it can attract dirt and debris.

Monitoring brake fluid levels and quality:

- Check the brake fluid levels regularly and top up if necessary.

- Inspect the brake fluid for any signs of contamination or degradation.

- If the brake fluid appears dark or contaminated, it may need to be flushed and replaced.

By following these preventive maintenance tips, you can ensure that your trailer brake controller functions optimally and helps maintain safe towing operation. Regular inspections, cleaning and protecting wiring connections, lubricating moving parts, and monitoring brake fluid levels are simple yet effective techniques to keep your trailer brake controller in excellent condition.

Frequently Asked Questions On Troubleshooting Techniques Of Trailer Brake Controller

How Do You Troubleshoot A Trailer Brake Controller?

To troubleshoot a trailer brake controller, start by checking the power source, then inspect the wiring connections and test the brake controller’s functionality.

Why Is My Trailer Brake Controller Not Working?

If your trailer brake controller isn’t working, it could be due to a blown fuse, improper wiring connections, or a faulty brake controller unit that needs replacement.

How Can I Fix A Trailer Brake Controller That Is Not Providing Enough Braking Power?

To fix a trailer brake controller that is not providing enough braking power, adjust the brake gain settings, check the brake system for any issues, and ensure the trailer’s weight is properly distributed.

What Should I Do If My Trailer Brakes Lock Up?

If your trailer brakes lock up, try adjusting the pressure on the brake controller, check the wiring connections, and ensure the brake shoes and drums are in good condition.

How Often Should I Inspect My Trailer Brake Controller?

It is recommended to inspect your trailer brake controller at least once a year or before long trips to ensure it is functioning properly.

Can A Faulty Trailer Brake Controller Be Repaired?

In some cases, a faulty trailer brake controller can be repaired, but it is often more cost-effective and safer to replace it with a new one.

Are There Any Safety Precautions When Troubleshooting A Trailer Brake Controller?

Yes, when troubleshooting a trailer brake controller, always wear safety gloves, avoid working on the controller while the vehicle is running, and follow the manufacturer’s instructions for safety guidelines.

Conclusion

Troubleshooting your trailer brake controller can be a frustrating task, but by following these techniques, you can quickly identify and resolve common issues. Start by checking the power source and ensure it is connected properly. Next, inspect the brake controller wiring for any damage or loose connections.

If everything checks out with the wiring, move on to testing the brake magnets and adjusting the gain settings. If the problem persists, consider checking the trailer’s ground wire and ensuring it is securely connected. Remember to consult the manufacturer’s instructions for your specific brake controller model for any additional troubleshooting steps.

By being diligent and methodical in your approach, you can ensure your trailer’s brake controller is functioning optimally, giving you peace of mind on your next towing adventure.