7 Best Strategies for Fixing Auto Electric Issues

When facing auto electric issues, implementing the 7 best strategies is crucial for maintaining your vehicle's functionality and safety.

From diagnosing common battery problems to tackling complex wiring issues, these strategies are essential for ensuring your car's electrical system operates smoothly.

By mastering these techniques, you can save time, money, and potential headaches down the road.

So, let's explore these effective strategies together and equip ourselves with the knowledge needed to troubleshoot and fix auto electric issues efficiently.

Key Takeaways

- Regular maintenance of battery, alternator, starter motor, and fuse box prevents auto electric issues.

- Prompt diagnosis and repair of ECM failures ensure optimal engine performance.

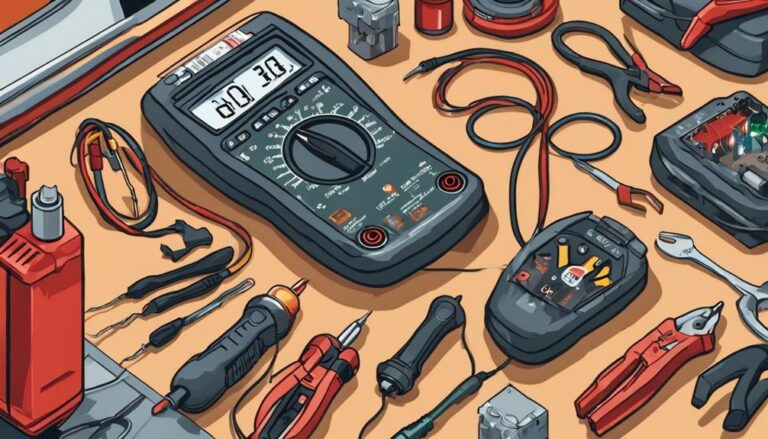

- Use multimeter testing to identify alternator and starter motor issues accurately.

- Clean terminals, check connections, and inspect components for early issue detection and prevention.

Identifying Dead Battery Causes and Solutions

When diagnosing dead battery issues in your vehicle, start by considering common causes and solutions to effectively address the problem.

Maximizing battery lifespan is crucial in avoiding dead batteries. Regular battery maintenance tips such as cleaning terminals and ensuring proper usage can significantly extend the life of your vehicle's battery.

Resolving Malfunctioning Alternator Issues

When your vehicle's alternator begins to fail, warning signs like dashboard lights and unusual sounds may indicate underlying issues. Troubleshooting alternator problems can involve testing with a multimeter to assess charging capabilities accurately.

Alternator Warning Signs

To identify potential alternator issues, vigilantly monitor warning lights like the battery light or charging system warning on your dashboard, listen for abnormal noises, and conduct voltage tests using a multimeter. Proper alternator maintenance, such as inspecting and replacing worn drive belts, can prevent malfunctions.

When diagnosing alternator issues, avoid common mistakes like solely blaming the battery for electrical problems. Testing the alternator with a multimeter to check voltage output is crucial in determining its health. Don't ignore warning signs like grinding or whining noises, as these could indicate serious problems that need immediate attention.

Troubleshooting Alternator Problems

As you troubleshoot alternator problems and work towards resolving malfunctioning issues, remember that the alternator plays a crucial role in charging the battery and powering your vehicle's electrical systems. Diagnosing alternator problems involves checking for voltage fluctuations and common issues like warning lights on the dashboard or unusual noises.

Utilizing a multimeter for testing can accurately pinpoint any malfunctions. Regular maintenance tips include inspecting and replacing worn drive belts to ensure the alternator's optimal performance. Conducting a charging system test can further aid in identifying specific alternator problems.

Stay proactive in monitoring the alternator's health to prevent unexpected breakdowns and keep your vehicle running smoothly.

Alternator Repair Tips

Inspect the alternator for visible signs of damage or wear before proceeding with repair procedures. When dealing with alternator issues, here are some DIY repair tips to help you resolve the problem efficiently:

- Check the Alternator Belt: Ensure the alternator belt is in good condition and properly tensioned to maintain optimal performance.

- Clean Electrical Connections: Clean any corrosion or debris from the alternator's electrical connections to ensure a secure and efficient electrical flow.

- Inspect for Loose Connections: Check for any loose connections within the alternator system, including wiring and mounting bolts, and tighten them as needed.

Fixing Faulty Starter Motor Problems

When troubleshooting faulty starter motor problems, start by testing the motor to identify any issues.

If the starter motor is found to be defective, prompt replacement or repair is crucial for proper functioning.

Ensuring proper maintenance of connections and the ignition switch is also essential to prevent starting issues.

Starter Motor Testing

To properly diagnose a faulty starter motor, utilize a multimeter to assess voltage and continuity, crucial steps in identifying potential issues.

When testing the starter motor, follow these steps:

- Inspect the Starter Solenoid: Look for signs of wear or damage as this component is essential for engaging the starter motor.

- Check Connections and Wiring: Examine for corrosion or loose connections that can affect the starter motor's performance.

- Listen for Clicking Sounds: If the starter motor clicks but doesn't crank the engine, it may indicate a faulty motor requiring replacement.

Starter Motor Replacement

When replacing a faulty starter motor, ensure thorough cleaning and lubrication of all connections to optimize performance. Starter motor maintenance is crucial for proper vehicle function.

Troubleshooting issues related to the starter motor can often be resolved by addressing connection cleanliness and lubrication. Upgrading the starter motor can also enhance overall performance.

Symptoms such as clicking noises during ignition attempts may indicate a faulty starter motor. If the engine fails to crank or start, the starter motor should be a primary focus for investigation.

Troubleshooting Bad Fuse Box Scenarios

Inspecting the fuse box regularly is essential for troubleshooting bad fuse box scenarios. To effectively address issues related to a malfunctioning fuse box, follow these steps:

- Fuse Box Maintenance: Regularly check the fuse box for any signs of damage, corrosion, or loose connections. Keeping the fuse box clean and free of debris is crucial to prevent electrical problems.

- Identifying Blown Fuses: When facing electrical issues, carefully inspect each fuse to identify any that may have blown. Look for a broken filament inside the fuse or discoloration, indicating a fault.

- Replacing Blown Fuses: Once a blown fuse is identified, replace it with a new one of the same amperage rating. Ensure the replacement fuse matches the original specifications to avoid further complications.

Addressing Bad Spark Plug Concerns

Address bad spark plug concerns by promptly replacing them to maintain optimal engine performance and combustion efficiency. Ensuring spark plug maintenance is crucial for ignition system optimization, as bad spark plugs can lead to misfires, rough idling, and decreased fuel economy. By regularly replacing spark plugs, you enhance combustion efficiency, reduce emissions, and improve power output. Quality spark plugs play a vital role in the ignition process, contributing to overall engine health. Ignoring signs of bad spark plugs can result in engine damage and costly repairs, making timely replacement a wise investment.

| Spark Plug Maintenance | Ignition System Optimization |

|---|---|

| Regular Replacement | Improved Combustion |

| Quality Spark Plugs | Reduced Emissions |

| Optimal Performance | Enhanced Power |

Handling Malfunctioning Ignition Coils

To maintain optimal engine performance and combustion efficiency, promptly addressing malfunctioning ignition coils is essential. Ignition coils play a vital role in converting low battery voltage into high voltage for sparking the spark plugs, impacting overall vehicle operation.

Here are key steps to handling malfunctioning ignition coils effectively:

- Regular Coil Pack Maintenance: Consistent upkeep of the coil pack can prevent unexpected failures and ensure peak performance of the ignition system.

- Thorough Ignition Coil Diagnostics: Utilize an ohmmeter to measure resistance and verify if the coils meet manufacturer specifications, aiding in pinpointing faulty components swiftly.

- Swift Solutions for Faulty Coils: Replace malfunctioning ignition coils promptly to prevent issues like engine misfires, rough idling, and decreased fuel efficiency, safeguarding both engine performance and longevity.

Resolving Engine Control Module Failures

For effective resolution of engine control module failures, understanding the underlying causes is paramount in implementing appropriate repair strategies. ECM failures can stem from various issues such as electrical faults, water damage, or software glitches. When faced with symptoms like engine performance issues or a lit check engine light, prompt ECM diagnostics and troubleshooting are essential to pinpoint the root cause accurately. Once the issue is identified, specialized knowledge and tools are crucial for repairing or replacing the faulty ECM. Reprogramming or resetting the ECM may be necessary to ensure proper functionality and optimal engine performance. Regular maintenance checks can help in early detection of ECM problems, potentially saving you from costly repairs down the line. By staying proactive and addressing ECM issues promptly, you can maintain your vehicle's efficiency and performance.

| ECM Diagnostics & Troubleshooting | ECM Reprogramming & Resetting |

|---|---|

| Identify underlying issues causing ECM failures. | Reprogram or reset the ECM for proper functionality. |

| Use specialized tools for accurate diagnosis. | Ensure optimal engine performance post-repair. |

Frequently Asked Questions

What to Do if Your Car Is Having Electrical Problems?

If your car is having electrical problems, utilize diagnostic tools and troubleshooting techniques to identify issues. Prioritize preventive maintenance like checking battery voltage and fuses. Seek professional help for persistent problems or uncertainty in fixing the issue.

What Is the Most Common Cause of Electrical Problems in Cars?

When it comes to electrical issues in cars, the most common culprit is often a dead or failing battery. Corroded connections and voltage fluctuations can exacerbate the problem. Regularly checking your battery's health can prevent many automotive electrical headaches.

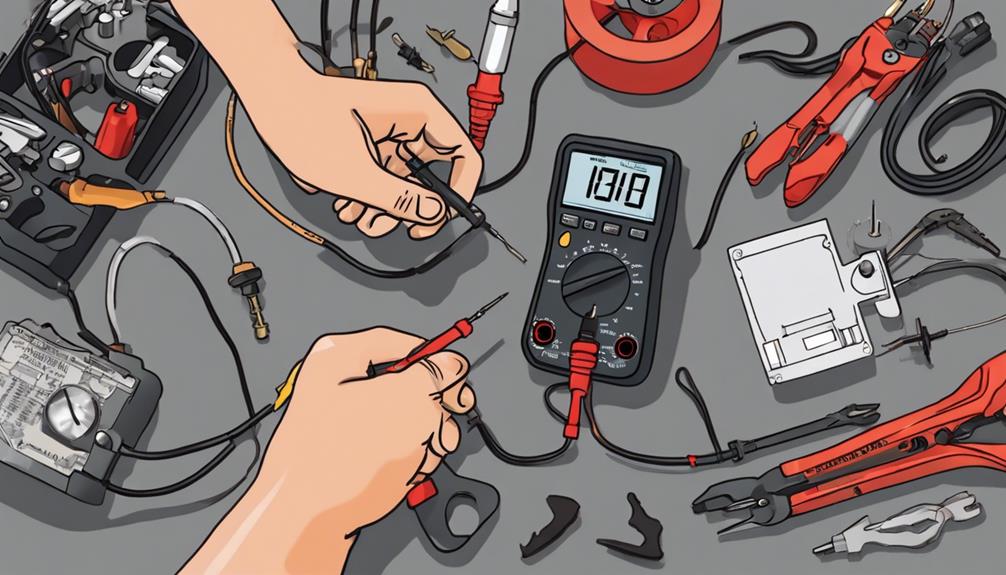

How Do You Fix an Electrical Short in a Car?

To fix an electrical short in a car, check the wiring harness for voltage drop. Inspect connectors and components for damage. Use a multimeter to pinpoint the short circuit. Replace or repair the faulty wiring to ensure safe operation.

How Do You Trace Electrical Problems in a Car?

To trace electrical problems in a car effectively, start by testing for voltage drop and inspecting wire insulation. Follow a systematic approach, checking components one by one, referencing manuals or diagrams for guidance.

Conclusion

In conclusion, by implementing the 7 best strategies for fixing auto electric issues, you can ensure your vehicle runs smoothly and efficiently.

From diagnosing dead battery causes to resolving engine control module failures, these solutions will keep you on the road with confidence.

So, don't wait until your car is as quiet as a library at midnight – take action now to prevent costly repairs and keep your vehicle in top condition.