7 Tips to Avoid Power Window Motor Burnout

You're driving down the road, enjoying the breeze from your open window, when suddenly, the power window motor grinds to a halt. How can you prevent this inconvenient situation from happening?

By implementing seven practical tips that can save you time, money, and frustration in the long run. Let's explore these simple yet effective strategies to guarantee your power window system stays in top condition for smooth operation.

Key Takeaways

- Regularly clean window tracks and seals to prevent motor strain and ensure efficient operation.

- Test power windows monthly to detect issues early and maintain smooth functionality.

- Clean switches and inspect wiring for reliable power delivery and prevent motor burnout.

- Properly lubricate regulators with silicone-based lubricants to reduce wear and prolong motor lifespan.

Regularly Clean Window Tracks

To maintain peak performance and prevent power window motor burnout, regularly cleaning the window tracks is essential. Window tracks can accumulate dirt and debris over time, increasing the friction on the window regulator. This added strain can lead to premature wear on the motor and potential burnout if left unaddressed. By engaging in regular maintenance of the window tracks, you can secure smooth movement of the window, reducing the workload on the power window motor and minimizing the risk of overheating.

Clean tracks facilitate efficient operation of the power windows, extending the lifespan of the motor and optimizing its performance. Removing dirt and obstructions from the tracks not only prevents costly motor replacements but also guarantees that your power windows function smoothly. Regularly inspecting and cleaning the window tracks is a simple yet effective way to maintain your vehicle's power window system, promoting longevity and reliable operation.

Inspect Window Seals

Regularly inspecting the window seals for cracks or wear is important to prevent water intrusion and potential damage. Proper maintenance of these seals is vital for the best functioning of your power windows and regulator system. Here are some key steps to follow:

- Inspect Regularly: Check the window seals monthly for any signs of wear, cracks, or damage. Addressing issues promptly can prevent water leakage and subsequent damage to the power window components.

- Clean Thoroughly: Use a mild soapy solution and a soft brush to clean the window seals. This helps maintain their flexibility and guarantees a proper seal when the windows are closed.

- Apply Protectant: After cleaning, apply a rubber protectant to the seals. This will help prolong their lifespan and enhance their sealing capabilities, keeping your vehicle's interior dry and protected.

Test Power Windows Often

Testing power windows frequently helps in early detection of potential issues before they escalate, guaranteeing peak functionality and preventing costly repairs. By regularly testing your power windows, you can sustain the health of the window regulators and overall system.

A recommended practice is to roll the windows up and down monthly to keep them in good working condition. During this testing, listen carefully for any abnormal noises that may indicate underlying problems with the power window motor or regulators. Promptly addressing any issues discovered during testing can prevent further damage and potential burnout of the power window motor.

Testing the power windows is a simple yet effective way to assure they're functioning properly and to avoid unexpected failures that could lead to expensive repairs. By incorporating regular testing of your power windows into your routine maintenance, you can prolong the lifespan of your window regulators and enjoy hassle-free operation.

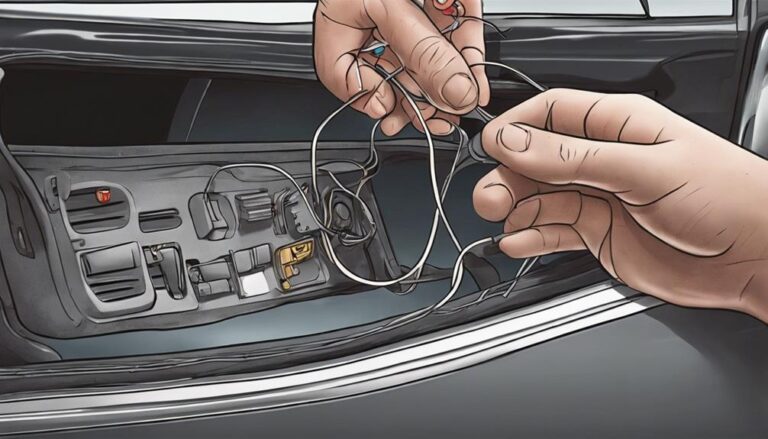

Maintain Switches and Wiring

Maintaining switches and wiring plays an important role in preventing power window motor burnout and ensuring the longevity of your vehicle's power window system. Keeping these components clean and well-maintained is critical for the overall health of your window motors and window regulator.

Here are essential tips to maintain switches and wiring effectively:

- Clean switches regularly: Use compressed air to remove debris buildup and guarantee proper electrical contact, preventing malfunctions in the window system.

- Inspect wiring harness: Regularly check for any signs of damage or wear on the wiring harness to address potential issues before they escalate and cause motor burnout.

- Address corrosion and loose connections: Look out for any corrosion or loose connections in the wiring and promptly address them to maintain reliable power delivery to the window motors, ensuring smooth operation.

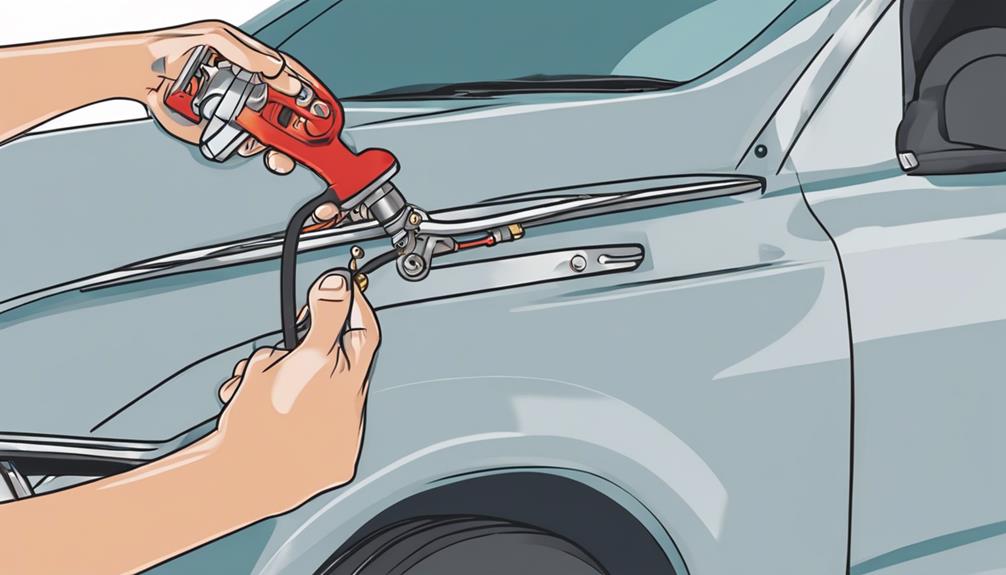

Lubricate Window Regulators

To guarantee the smooth operation and longevity of your power window system, proper lubrication of the window regulators is essential in reducing wear and preventing motor burnout. Window regulators play an important role in the movement of your power windows, and keeping them well-lubricated is necessary for best performance.

By applying the appropriate lubricant, you can greatly decrease friction and wear on the moving parts, ultimately extending the lifespan of the regulators. It's recommended to use silicone-based lubricants for window regulators as they're compatible with the materials and offer long-lasting protection.

Regular lubrication not only helps maintain the efficiency of the window regulators but also prevents strain on the motor, ensuring smooth operation. Neglecting to lubricate the window regulators can lead to issues such as sticking, slow operation, and potential motor burnout in power window systems.

Make lubricating your window regulators a part of your routine maintenance to avoid costly repairs and keep your power windows functioning optimally.

Care for Power Window Motors

For important performance and longevity of your power window motors, it's essential to implement proper care and maintenance practices to prevent overheating and potential burnout.

To guarantee your power window motors operate at their best and avoid common window issues, consider the following:

- Regular Cleaning: Dust, dirt, and debris can accumulate in the window tracks over time, causing increased friction and strain on the motor. Regularly clean the tracks with a soft brush or cloth to prevent unnecessary wear on the motor.

- Lubrication: Proper lubrication of the window tracks is vital for smooth operation and reduced strain on the motor. Use a silicone-based lubricant to keep the tracks well-lubricated and prevent motor overheating.

- High-Quality Replacement Motors: When replacing a faulty motor, opt for high-quality replacement motors to assure durability and longevity. Poor quality motors may lead to premature failure and more frequent window issues.

Shield Against Extreme Temperatures

Regularly monitoring and managing the impact of extreme temperatures on your power window motors is key to preventing premature burnout and ensuring peak functionality. Extreme temperatures, whether hot or cold, can have a notable effect on the performance and lifespan of your power window motor. To shield against these temperature extremes, it is important to take preventive measures.

| Avoid using excessive power in extreme cold | Refrain from forcing frozen windows open | Utilize window shades in extreme heat | Protect against extreme temperatures |

|---|---|---|---|

| Excessive cold can strain the motor | Forcing frozen windows can damage components | Window shades reduce motor workload | Shielding helps prevent burnout |

Avoid using your power windows excessively in extreme cold conditions as this can strain the motor. Refrain from trying to force frozen windows open, as it may lead to damage to the motor components. In extreme heat, consider using window shades to reduce the workload on the motor. By protecting your power window motor against extreme temperatures, you can help prevent premature burnout and ensure the best functionality.

Frequently Asked Questions

How Do You Keep a Car Window up When the Motor Is Broken?

To keep a car window up when the motor is broken, prop it temporarily with a wooden or rubber wedge, secure it using duct tape, support it with a rolled-up towel, and seek professional repair services promptly.

How Long Should a Power Window Motor Last?

Your power window motor typically lasts 10-20 years with proper care. Factors like usage frequency, climate, and motor quality impact its longevity. Regular cleaning and lubrication of tracks extend its life. Avoid overloading and address issues promptly.

Why Does My Window Motor Keep Breaking?

You keep replacing that window motor because you neglect maintenance and fail to troubleshoot properly. Take time for motor maintenance, address wiring issues, and consider DIY repairs or professional help. Prevent burnout with simple care.

How Do Window Motors Go Bad?

To prevent window motor issues, maintain your motor regularly. Address electrical problems promptly. Use proper lubrication techniques. Neglecting maintenance can lead to overheating and burnout. Take care to extend your motor's lifespan.

Conclusion

To sum up, by following these 7 tips to avoid power window motor burnout, you can guarantee the longevity and efficiency of your power window system.

Remember, prevention is key to avoiding costly repairs and maintaining a smooth driving experience.

Just like a well-maintained engine keeps your car running smoothly, taking care of your power windows will make sure they operate seamlessly for years to come.

So, stay proactive and enjoy hassle-free window operation.