7 Best Ways Oil Viscosity Affects Engine Performance

When it comes to your car's engine, oil viscosity isn't just a technical term thrown around. It has a significant impact on how well your engine performs and how long it lasts.

Picture this: the wrong oil viscosity can lead to increased friction, reduced fuel efficiency, and potential engine damage.

But what exactly are the seven key ways oil viscosity influences your engine's performance? Stay tuned to uncover the crucial insights that could make a world of difference for your vehicle's health and efficiency.

Key Takeaways

- Proper oil viscosity protects critical components and enhances engine longevity.

- Choosing the right viscosity boosts fuel efficiency and reduces wear on moving parts.

- Optimal viscosity ensures smooth cold starts and minimizes engine wear during ignition.

- Adhering to manufacturer's recommendations on viscosity is crucial for engine performance and longevity.

Impact on Engine Wear and Tear

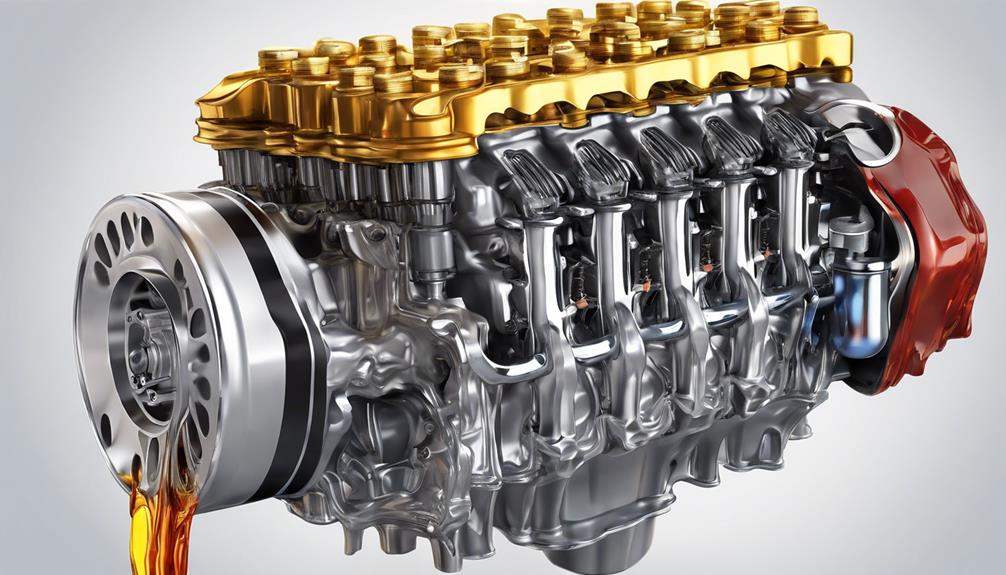

Proper selection of oil viscosity significantly influences engine wear and tear by directly affecting the protective film's thickness and strength on critical components. The right viscosity oil plays a crucial role in friction reduction and wear prevention within your engine. When the oil's viscosity matches the manufacturer's recommendations, it forms a robust protective layer on engine parts, reducing friction and preventing premature wear.

This protective film acts as a barrier, preventing metal-to-metal contact that leads to wear and tear. Using the correct viscosity oil ensures that critical components receive adequate lubrication, minimizing the risk of damage due to friction. On the other hand, using an improper viscosity can compromise this protective film, increasing the likelihood of wear on engine components.

Influence on Fuel Efficiency

Lower viscosity heavy-duty engine oils can have a significant impact on fuel consumption, with potential annual savings ranging from 0.9% to 2.2%. The relation between engine oil viscosity and fuel efficiency is direct, as lower viscosity oils reduce engine friction, thus enhancing overall efficiency.

Upgrading to advanced engine oils like API CK-4 and FA-4 can lead to substantial fuel savings. Finding the right balance between fuel economy and engine protection is crucial for optimal performance.

Fuel Consumption Impact

Enhancing fuel efficiency through adjustments in engine oil viscosity can yield significant reductions in fuel consumption, leading to cost savings and improved overall performance. Lowering engine oil viscosity can result in fuel consumption reductions of 0.9-2.2% annually. Engine friction decreases with lower viscosity oil, enhancing fuel economy by reducing energy loss through friction.

Upgrading to modern engine oils like API CK-4 and FA-4 can lead to substantial fuel savings due to improved efficiency. Balancing fuel economy with engine protection is crucial when selecting the right viscosity oil for optimal performance. Consider these factors to maximize fuel efficiency and save on costs effectively.

Engine Efficiency Relation

Making informed decisions about engine oil viscosity directly impacts fuel efficiency, playing a pivotal role in optimizing engine performance.

The engine efficiency correlation with oil viscosity optimization is evident in the potential fuel savings of 0.9-2.2% annually achievable by using lower viscosity heavy-duty engine oil. Lower viscosity oil reduces engine friction, leading to enhanced fuel economy by minimizing energy losses.

Upgrading to API CK-4 and FA-4 engine oils further enhances fuel efficiency, showcasing the importance of selecting the right viscosity.

Balancing fuel economy and engine protection is key when considering oil viscosity, ensuring that the engine operates efficiently while maintaining longevity.

Effects on Cold-Start Performance

For optimal engine performance in cold conditions, the viscosity of the oil plays a critical role in facilitating smooth cold-start operations. To ensure your engine starts up efficiently when faced with cold weather challenges, consider the following:

- Choose the Right Viscosity: Opt for oils like 0W-20 or 5W-30 with lower viscosity grades as they aid quick engine start-up in chilly weather.

- Reduce Engine Wear: Proper cold-start viscosity is essential as it reduces engine wear during initial ignition, thus enhancing engine longevity.

- Cold Crank Simulator Test: This test measures the dynamic viscosity of oil at low temperatures, ensuring its effectiveness in cold-start situations.

- Engine Protection: Selecting the optimal viscosity grade is crucial for achieving the best cold-start performance and ensuring your engine is protected during start-up.

Relationship With Engine Temperature

When it comes to engine temperature, the relationship with oil viscosity plays a crucial role in your engine's performance.

Understanding how temperature impacts viscosity, the operating temperature range, and the engine cooling effectiveness is essential for optimal engine function.

Properly managing these factors ensures efficient lubrication and protection for your engine across varying temperature conditions.

Temperature Impact on Viscosity

With fluctuating temperatures, engine oil viscosity undergoes changes that directly impact its ability to effectively lubricate engine components. Understanding the temperature impact on viscosity is crucial for maintaining engine performance.

Here are four key points to consider:

- Viscosity Modulation: Temperature sensitivity causes viscosity to vary, affecting the oil's flow and lubrication efficiency.

- Low-Temperature Viscosity: Winter ratings determine oil flow during cold starts, influencing engine protection in colder climates.

- High-Temperature Viscosity: Summer ratings impact oil flow at operating temperatures, crucial for engine performance in hotter conditions.

- Choosing the Right Grade: Selecting the appropriate viscosity grade based on temperature ensures optimal lubrication, safeguarding engine operation.

Operating Temperature Range

Operating within an appropriate temperature range is essential for ensuring that engine oil viscosity maintains optimal lubrication capabilities for engine components. Viscosity regulation is crucial for the oil to flow effectively in both cold-start conditions and high-temperature environments.

The first number in the viscosity grade indicates the oil's behavior in cold temperatures, while the second number reflects its performance in hotter conditions. Thermal stability plays a key role in maintaining the viscosity of the oil across a wide operating temperature range, ensuring consistent lubrication and protection for engine parts.

Engine Cooling Effectiveness

Effective engine cooling relies significantly on the ability of the oil to efficiently carry heat away from engine components. When considering engine cooling effectiveness in relation to oil viscosity, several key points come into play:

- Heat Dissipation: Oil viscosity impacts how effectively heat is dissipated from the engine, affecting overall temperature regulation.

- Cooling Capacity: Thicker oil with higher viscosity can reduce the cooling capacity of the oil, potentially leading to elevated engine temperatures.

- Optimal Viscosity Selection: Selecting the proper viscosity is crucial for maintaining ideal engine operating temperatures and preventing overheating.

- Critical Cooling Efficiency: The choice of oil viscosity plays a critical role in ensuring efficient heat dissipation, which is vital for overall engine health and performance.

Impact on Lubrication of Engine Parts

Proper selection of oil viscosity directly influences the lubrication of engine parts, reducing friction and wear for optimal performance. The viscosity of the oil determines its ability to flow efficiently through the engine components, ensuring effective lubrication where needed.

By choosing the correct viscosity, you can minimize heat buildup and friction within the engine, leading to smoother operation and increased longevity of the parts. The oil's viscosity plays a crucial role in reducing wear on moving components, directly impacting the engine's efficiency and durability over time.

It's essential to maintain the right viscosity oil to prevent damage to engine parts and to guarantee the engine's efficient operation. Therefore, ensuring that the oil viscosity matches the engine's requirements is key to maximizing lubrication effectiveness and minimizing friction-induced wear, ultimately enhancing the overall performance and longevity of your engine.

Connection to Engine Power Output

The relationship between oil viscosity and engine power output becomes evident when considering how well the oil flows through engine components, directly impacting performance. To understand this connection better, consider the following:

- Oil Flow: The viscosity of the oil determines how easily it moves through the engine. Thicker oil can struggle to flow smoothly, leading to power loss and reduced engine efficiency.

- Power Loss: When the oil viscosity is too high, the engine experiences increased resistance, resulting in power loss during operation. This can affect the overall performance of the engine.

- Friction Reduction: Proper viscosity selection reduces friction between moving parts, optimizing power output. Lower viscosity oils can enhance engine efficiency by minimizing resistance and improving overall performance.

- Operating Conditions: Engine power can be compromised if the oil viscosity isn't suitable for the specific operating conditions. Ensuring the correct viscosity is maintained is crucial for maximizing power output and overall engine performance.

Effects on Engine Longevity

To enhance engine longevity, ensure that the oil viscosity matches the manufacturer's recommendations for optimal performance and wear protection. Maintenance practices play a crucial role in preserving the engine's lifespan. Proper oil viscosity reduces wear on engine components, minimizing friction and preserving their integrity over time. It's essential to adhere to recommended oil change intervals to maintain the correct viscosity.

Failure to do so can result in premature engine failure and expensive repairs. Optimal viscosity provides effective lubrication, preventing excessive wear on moving parts and protecting critical engine components. By following the manufacturer's guidelines for oil viscosity and regular maintenance practices, you can significantly impact engine longevity.

Frequently Asked Questions

What Is the Benefit of Using a Higher Viscosity Oil?

Using a higher viscosity oil benefits you by providing improved engine protection and longevity. It helps reduce wear, maintain lubrication, and prevent breakdown, ultimately enhancing fuel efficiency and prolonging your engine's life.

Does Thicker Oil Increase Performance?

Thicker oil doesn't directly increase performance; it can harm engine efficiency. Viscosity impacts how smoothly parts move. Optimal viscosity ensures peak performance. Compare oil weights to enhance engine efficiency and longevity without sacrificing power.

Is Thicker Oil Better for Older Engines?

For older engines, thicker oil can be like a shield, protecting against wear and tear. It helps maintain pressure, reduces consumption, minimizes leaks, and quiets engine noise. Opt for the right oil type for engine longevity.

How Does the Oil Improve the Performance of the Engine?

To enhance engine performance, oil lubrication plays a vital role in reducing friction between components, ensuring smooth operation. Proper viscosity levels maintain a protective film, preventing wear and tear. This leads to optimal lubrication, preventing overheating and damage while improving fuel efficiency.

Conclusion

You have now seen how oil viscosity directly impacts engine performance in various ways. From reducing wear and tear to influencing fuel efficiency and cold-start performance, the choice of oil viscosity is crucial for maintaining optimal engine health.

By understanding these effects and selecting the right viscosity for your engine, you can ensure smooth operation, increased longevity, and improved overall performance. Make the right choice for your engine's needs to keep it running at its best.