Expert Tips for Troubleshooting Engine Performance Issues

If your car is experiencing a rough idle or decreased fuel efficiency, you might be facing engine performance issues that require attention.

By understanding common problems and utilizing diagnostic tools effectively, you can pinpoint the root cause of the issue.

However, knowing where to start can be overwhelming.

Stay tuned to discover practical expert tips that can help you troubleshoot engine performance problems efficiently and get your vehicle back on track.

Key Takeaways

- Conduct compression testing to pinpoint engine issues accurately.

- Utilize sensor diagnostics and OBD-II scanners for efficient troubleshooting.

- Inspect ignition system components for optimal performance.

- Address fuel system, air intake, and exhaust concerns promptly for improved engine operation.

Common Engine Performance Issues

If your vehicle is experiencing common engine performance issues, it's essential to identify the root causes promptly for optimal operation and longevity. One crucial diagnostic tool to assess engine health is compression testing. This test measures the pressure in each cylinder, providing insight into the engine's overall condition and detecting issues such as worn piston rings, cylinder wall damage, or valve problems. By conducting compression testing, you can pinpoint the specific cylinder causing performance issues and take targeted corrective actions.

Moreover, when addressing common engine performance issues, it's vital to consider emission regulations. Issues like misfires and rough idling can lead to increased emissions, potentially causing your vehicle to fail emission tests and harm the environment. By resolving these problems promptly, you not only ensure your vehicle complies with emission standards but also improve fuel efficiency and overall engine health. Stay proactive in diagnosing and resolving engine performance issues to maintain your vehicle's efficiency and meet emission regulations.

Diagnostic Tools and Techniques

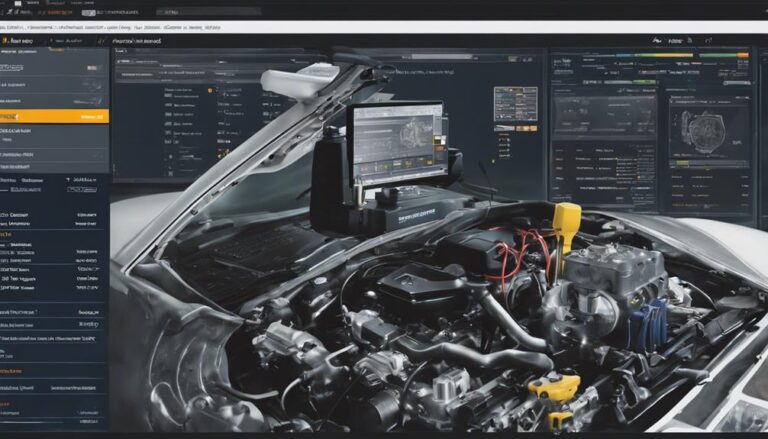

When diagnosing engine performance issues, utilizing diagnostic tools and techniques is essential for accurate assessment and efficient troubleshooting. Sensor diagnostics play a crucial role in identifying malfunctions within the engine system.

Tools like OBD-II scanners provide real-time data, aiding in performance tuning and system analysis. By interpreting this data correctly, you can pinpoint specific problems such as sensor malfunctions, fuel system issues, and ignition problems.

Techniques like checking trouble codes help streamline the diagnostic process, allowing for a more focused approach to resolving issues. Professional mechanics heavily rely on these tools to diagnose engine performance problems effectively.

Understanding the results obtained from diagnostic tools is key to successful troubleshooting and timely repairs. By integrating sensor diagnostics, data interpretation, and system analysis into your diagnostic process, you can navigate through engine performance issues with precision and confidence.

Troubleshooting Ignition System Problems

To troubleshoot ignition system problems effectively, start by checking the condition, connections, and gaps of the spark plugs. Testing the spark plug condition can reveal issues such as fouling, wear, or improper gaps that could lead to misfires. Additionally, inspecting the ignition coils with a multimeter to ensure resistance levels fall within the manufacturer's specifications is crucial for proper spark generation. The ignition control module should be examined for any signs of damage that could impact spark timing, potentially causing engine performance problems. Furthermore, a thorough check of the distributor cap and rotor for cracks or carbon build-up is essential to guarantee efficient spark distribution. Lastly, don't forget to assess the camshaft and crankshaft position sensors to verify accurate ignition timing signals and diagnose misfire issues promptly.

| Ignition System Component | Check | Potential Issues |

|---|---|---|

| Spark Plugs | Condition, Connections, Gaps | Fouling, Improper Gaps |

| Ignition Coils | Resistance Levels | Misfires |

| Ignition Control Module | Signs of Damage | Spark Timing |

| Distributor Cap and Rotor | Cracks, Carbon Build-up | Inefficient Spark Dist. |

| Camshaft/Crankshaft Sensors | Accuracy of Signals | Misfire Diagnosis |

Addressing Fuel System Concerns

Inspect the fuel system components thoroughly to identify and resolve any issues affecting fuel delivery and engine performance. Begin by checking the fuel pressure and volume to ensure the engine receives an adequate supply.

If there are fuel delivery problems, inspect the fuel filters for clogs or debris that may obstruct the flow. Pay close attention to the fuel injectors, addressing any clogging or malfunctions promptly to maintain optimal operation.

Test the fuel pump functionality to verify a consistent fuel supply for efficient combustion. Regular maintenance of injectors is crucial for proper engine performance.

Ensure you monitor fuel quality regularly and consider using additives when necessary to prevent fuel system issues. By staying proactive with fuel pressure checks and injector maintenance, you can uphold a healthy fuel system and keep your engine running smoothly.

Resolving Air Intake and Exhaust Issues

To ensure optimal engine performance, meticulous examination of the air intake system and exhaust components is imperative.

- Check for Air Intake Issues: Inspect the intake manifold for any clogs, leaks, or restrictions that could be impacting the engine's performance. Ensure the air filters are regularly checked and replaced as recommended by the manufacturer to maintain optimal airflow.

- Address Exhaust Problems: Promptly address any exhaust leaks to prevent backpressure issues that can affect the engine's efficiency. Proper sealing of the exhaust manifold is crucial for maintaining engine performance and fuel efficiency.

- Consider Upgrades: Think about upgrading to a high-flow air filter or intake system to increase air intake and power, enhancing the overall performance of your engine. Upgrades like these can lead to improved efficiency and power output, providing a more satisfying driving experience.

Frequently Asked Questions

How Do You Check Engine Performance?

To check engine performance, conduct a compression test to assess internal health. Monitor fuel consumption for efficiency evaluation. Seek professional guidance from a mechanic for a comprehensive assessment and diagnosis using specialized tools.

How Do You Diagnose a Bad Engine?

To diagnose a bad engine, listen for engine misfires and knocking. Use diagnostic tools like OBD-II scanners to pinpoint issues. Check spark plugs, fuel system, vacuum leaks, and timing belt. Consult a mechanic for expert guidance.

How Do I Check My Car Engine Performance?

To check your car engine performance, start with a thorough examination for misfires, rough idling, or power loss. Employ OBD-II scanners for diagnostics and inspect components like spark plugs and sensors. Address issues promptly for optimal performance tuning.

How Can I Improve My Engine Performance?

To improve engine performance, consider performance tuning with a chip, power upgrades like spark plugs, cold air intake for better airflow, and exhaust enhancements. Regularly maintain filters and adjust settings for optimized power output and efficiency.

Conclusion

Just as a skilled mechanic diagnoses and repairs a car's engine to ensure optimal performance, you have the power to troubleshoot and address any issues that may arise in your own life.

By staying proactive, using the right tools, and seeking help when needed, you can navigate through challenges with ease and achieve peak performance in all aspects of your life.

Remember, just like a well-maintained engine, a well-maintained life runs smoothly and efficiently.