How To Refill A Floor Jack With Hydraulic Fluid

Hydraulic floor jacks are commonly used in automotive and industrial settings for lifting heavy loads. However, over time, the hydraulic fluid in these jacks can become depleted or contaminated, affecting their performance and potentially causing damage. Refilling the floor jack with hydraulic fluid is a necessary maintenance task to ensure its proper functioning.

In this article, we will provide a step-by-step guide on how to refill a floor jack with hydraulic fluid. By following these instructions carefully, users will be able to maintain and prolong the lifespan of their floor jacks.

The article begins by outlining the necessary tools and materials required for the task. It then proceeds to explain how to locate the hydraulic fluid reservoir and release pressure from the jack. Subsequently, readers will learn how to remove and replace the filler plug as well as add hydraulic fluid to the reservoir. The article concludes by discussing regular maintenance practices and troubleshooting tips.

This technical guide aims to provide a comprehensive understanding of refilling floor jacks with hydraulic fluid while promoting safe practices within an audience seeking knowledge on this subject matter.

Gather the Necessary Tools and Materials

To begin the process of refilling a floor jack with hydraulic fluid, it is essential to gather the required tools and materials in order to ensure a smooth and efficient operation. The first step is to determine the appropriate type of hydraulic fluid to use for your specific floor jack model. Different floor jacks may require different types of hydraulic fluids, such as mineral oil or synthetic oil. It is crucial to consult the manufacturer’s manual or contact their customer support for guidance on selecting the correct fluid.

Common issues when refilling a floor jack include using an incorrect type of hydraulic fluid or overfilling the reservoir. Using an improper fluid can lead to reduced performance and potential damage to internal components. Overfilling the reservoir can cause leaks or excessive pressure, which can be hazardous during use.

Once you have identified the appropriate hydraulic fluid for your floor jack, gather all necessary materials including a funnel, clean rags or paper towels, and safety goggles. These items will help facilitate a clean and safe refill process.

To locate the hydraulic fluid reservoir on your floor jack, refer to the manufacturer’s manual for specific instructions. Typically, it is located near the pump assembly. By following these guidelines and gathering all necessary tools and materials, you will be prepared for successfully refilling your floor jack with hydraulic fluid without encountering any major issues.

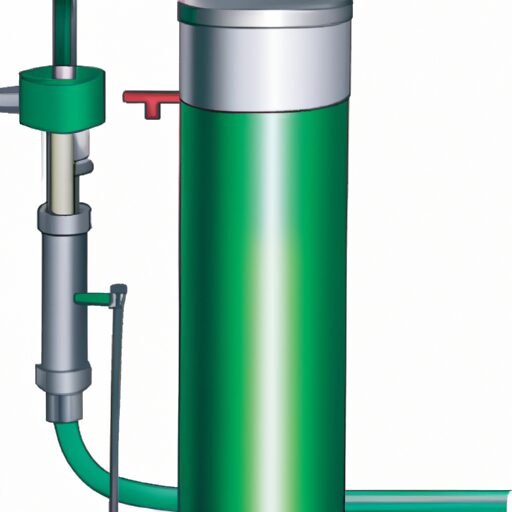

Locate the Hydraulic Fluid Reservoir

Located in the lower part of the floor jack, the area where hydraulic pressure is created and stored can be found. This area is known as the hydraulic fluid reservoir. It plays a crucial role in the functioning of the floor jack by holding and distributing hydraulic fluid to generate the necessary pressure for lifting heavy objects.

Before refilling the floor jack with hydraulic fluid, it is important to check for any leaks in the reservoir. A leak could indicate a damaged seal or gasket, which needs to be repaired before adding new fluid. Additionally, it is essential to dispose of any old hydraulic fluid properly. Hydraulic fluids are considered hazardous waste and should not be poured down drains or disposed of in regular trash bins. Local recycling centers or automotive service stations may provide options for proper disposal.

With these considerations addressed, we can now move on to releasing the pressure in the jack, which will allow us to safely refill it with fresh hydraulic fluid.

Release the Pressure in the Jack

Releasing the pressure in the jack ensures a safe and controlled environment for refilling with fresh hydraulic fluid. Before beginning this process, it is important to take safety precautions such as wearing protective gloves and eyewear. To release the pressure, locate the release valve on the jack. This valve is typically located near the handle or on the side of the jack cylinder.

To provide a clearer understanding, refer to the table below which depicts the steps involved in releasing pressure from a floor jack:

| Step | Procedure |

|---|---|

| 1 | Locate the release valve |

| 2 | Turn the release valve counterclockwise to open it |

| 3 | Slowly pump the handle several times to lower any lifted load |

Once you have successfully released all pressure from your floor jack, you can proceed to remove the filler plug. This plug allows access to refill hydraulic fluid in later steps. Taking these precautionary measures ensures that there is no residual pressure within your floor jack before proceeding further.

Next, we will discuss how to remove the filler plug for easy access to refill hydraulic fluid.

Remove the Filler Plug

The next step involves removing the filler plug to allow for easy access when adding fresh hydraulic fluid. To remove the filler plug, follow these steps:

-

Locate the filler plug on the side or top of the floor jack’s reservoir. It is typically a small screw or bolt.

-

Use an appropriate tool, such as a wrench or socket, to loosen and remove the filler plug. Make sure to turn it counterclockwise.

-

Once removed, inspect the filler plug for any signs of damage or wear. If necessary, replace it with a new one to prevent leaks and ensure proper sealing.

-

While the filler plug is off, check for any leaks around the area where it was located. Common problems include worn seals or loose connections that may require repair before proceeding.

After removing and inspecting the filler plug, you are now ready to add hydraulic fluid to the reservoir in order to refill your floor jack properly.

Transition: With the filler plug removed and any necessary repairs made, you can now proceed to add hydraulic fluid to the reservoir in order to complete this maintenance task effectively

Add Hydraulic Fluid to the Reservoir

To ensure proper functioning and longevity of the equipment, it is essential to replenish the reservoir with the necessary lubricant. When adding hydraulic fluid to the floor jack, it is important to avoid common mistakes that can compromise its performance. One common mistake is overfilling the reservoir, which can lead to leaks and damage to internal components. It is crucial to follow the manufacturer’s instructions regarding the appropriate fluid level for your specific jack model.

Another mistake to avoid is using the wrong type of hydraulic fluid. There are different types available, each designed for specific applications and operating conditions. Choosing the right hydraulic fluid ensures optimal performance and protects against wear and tear. Some types include mineral-based fluids, which offer good lubrication properties and are suitable for general-purpose use. Synthetic fluids, on the other hand, provide enhanced thermal stability and resistance to oxidation, making them ideal for heavy-duty applications or extreme temperatures.

Before adding hydraulic fluid, it is important to clean any dirt or debris from around the filler plug area to prevent contamination of the system. Once cleaned, remove the filler plug using a wrench or socket set. Carefully pour in the recommended amount of hydraulic fluid into the reservoir until it reaches the designated fill line.

In conclusion, avoiding common mistakes when adding hydraulic fluid such as overfilling or using incorrect types ensures proper functioning of your floor jack. After adding hydraulic fluid following these guidelines, you can proceed to replace the filler plug and test your jack’s performance in subsequent steps.

Replace the Filler Plug and Test the Jack

Replacing the filler plug and conducting performance tests are crucial steps in ensuring the proper functioning of a hydraulic system. After adding hydraulic fluid to the reservoir, it is essential to replace the filler plug securely. This ensures that no air or contaminants enter the system, which could compromise its efficiency and reliability. Additionally, it is important to test the jack’s lifting capacity to ensure that it can handle the intended load safely.

To test the jack’s lifting capacity, start by positioning it on a flat and stable surface. Place a known weight on top of the jack and slowly pump the handle until you reach maximum height. Observe if there are any leaks, unusual noises, or signs of instability during this process. If everything appears normal, carefully lower the jack back down.

If there are any issues with stability or lifting capacity during testing, it may indicate a problem with either the hydraulic hose or other components of the floor jack. In such cases, replacing the hydraulic hose might be necessary to restore proper functionality.

In conclusion, replacing the filler plug and performing tests on a floor jack after refilling it with hydraulic fluid are crucial for maintaining its optimal performance. Regular maintenance and troubleshooting tips further contribute to extending its lifespan and ensuring safe operations without compromising efficiency or reliability.

Regular Maintenance and Troubleshooting Tips

Regular maintenance and troubleshooting tips are essential for ensuring the optimal performance and longevity of a hydraulic system. When it comes to floor jack troubleshooting, there are several signs that indicate low hydraulic fluid levels. By being aware of these signs, one can take necessary actions to maintain the efficiency of their floor jack.

Signs of low hydraulic fluid in a floor jack include slow or jerky lifting movements, difficulty in reaching maximum height, and visible leaks around the piston or seals. To troubleshoot these issues, one should first check the fluid level by locating the filler plug and ensuring it is properly tightened. If the fluid is indeed low, it is crucial to refill it with the recommended hydraulic fluid.

In addition to maintaining proper fluid levels, regular inspection of seals for wear or damage is important. Any worn-out or damaged seals should be promptly replaced to prevent further issues. Furthermore, lubricating moving parts such as pistons and release valves can enhance overall performance and reduce friction.

To summarize, regular maintenance practices such as checking fluid levels, inspecting seals, and lubricating moving parts are vital for keeping a floor jack working efficiently. By being vigilant about these troubleshooting tips and addressing any issues promptly, users can maximize their floor jack’s lifespan while ensuring smooth operation when needed.

Frequently Asked Questions

Can I use any type of hydraulic fluid to refill my floor jack?

Using the wrong hydraulic fluid in a floor jack can have disastrous consequences. Just like using gasoline instead of diesel fuel in a car engine, the incorrect fluid can cause damage and lead to costly repairs.

How often should I refill the hydraulic fluid in my floor jack?

The frequency of checking the hydraulic fluid in a floor jack depends on usage and manufacturer recommendations. Signs of low hydraulic fluid include slow lifting or lowering, increased noise, and difficulty in operation.

What should I do if I cannot locate the hydraulic fluid reservoir in my floor jack?

If you cannot locate the hydraulic fluid reservoir in your floor jack, troubleshooting tips suggest checking the user manual or contacting the manufacturer for guidance. Alternative methods may include seeking assistance from a professional mechanic or hydraulic equipment specialist.

Is it necessary to release the pressure in the jack before refilling it with hydraulic fluid?

Releasing pressure in a floor jack before refilling it with hydraulic fluid is crucial. Failing to do so can result in catastrophic consequences, such as sudden explosions, rendering the jack unusable and causing potential harm to individuals nearby.

What should I do if the jack is not functioning properly after refilling it with hydraulic fluid?

When a floor jack is not functioning properly after refilling it with hydraulic fluid, troubleshooting tips include checking for leaks, ensuring proper fluid levels, inspecting the pump and release valve, and considering alternative solutions such as replacing faulty parts.

Conclusion

In conclusion, refilling a floor jack with hydraulic fluid is a relatively simple task that can be done with the right tools and materials. By following the steps outlined in this article, you can ensure that your floor jack remains in good working condition and is able to provide the necessary support for lifting heavy objects. It is important to regularly maintain your floor jack and troubleshoot any issues that may arise to prevent accidents or damage. One interesting statistic is that proper maintenance of hydraulic jacks can extend their lifespan by up to 50%.