How to Check Oil Pressure Sensor

To check oil pressure sensor, use an OBD scanner to monitor pressure levels and identify issues promptly. A malfunction can lead to engine damage.

Are you experiencing engine problems or curious about your vehicle’s oil pressure sensor? Proper maintenance of your oil pressure sensor is crucial for the smooth operation of your vehicle. In this guide, we will discuss the importance of checking the oil pressure sensor regularly and how to do it efficiently.

By following these simple steps, you can ensure the optimal performance of your engine and prevent potential costly repairs down the line. Let’s dive into the world of oil pressure sensors and learn how to keep your vehicle running smoothly.

Importance Of Oil Pressure Sensor

The oil pressure sensor is an essential component of your vehicle, responsible for monitoring the oil pressure levels and ensuring the smooth functioning of the engine. It plays a crucial role in maintaining the engine’s overall health and preventing potential damage.

Ensuring Proper Engine Lubrication

One of the major roles of the oil pressure sensor is to monitor the oil pressure levels in your engine. It detects any fluctuations or abnormalities in the pressure and alerts you about potential issues.

- Proper Engine Lubrication: The oil pressure sensor ensures that your engine is properly lubricated at all times. Adequate lubrication is crucial for reducing friction and heat, which in turn helps to prevent excessive wear and tear on engine components. Without sufficient lubrication, the engine can seize up and suffer irreversible damage.

- Timely Oil Changes: By monitoring the oil pressure, the sensor can also indicate when it’s time for an oil change. Over time, the oil in your engine loses its effectiveness and becomes contaminated with dirt and debris. Regular oil changes are essential to maintain optimal engine performance and prolong its lifespan.

- Preventing Engine Overheating: Another vital function of the oil pressure sensor is to prevent engine overheating. It ensures that the oil is flowing smoothly through the engine, carrying away the heat generated during combustion. If the oil pressure drops, it could indicate a restriction in the oil flow, potentially leading to overheating.

Detecting Potential Engine Issues

The oil pressure sensor acts as an early warning system, alerting you to any potential engine issues before they become major problems. By monitoring the oil pressure levels, it can detect various engine malfunctions and irregularities:

- Low Oil Pressure: A sudden drop in oil pressure could indicate a leak, oil pump failure, or clogged oil filter. These issues can significantly affect the engine’s performance and should be addressed promptly to prevent further damage.

- High Oil Pressure: On the other hand, excessively high oil pressure can be a sign of a blocked oil passage, a malfunctioning relief valve, or a faulty pressure sensor itself. It’s important to investigate and resolve the underlying cause to prevent potential engine damage.

- Oil Contamination: Monitoring the oil pressure can also help in detecting oil contamination. If the pressure readings are inconsistent or abnormal, it could indicate the presence of coolant or fuel in the oil, which may lead to internal engine damage if not addressed.

Regularly checking and maintaining your oil pressure sensor can help prevent costly repairs and ensure the longevity of your engine. By understanding the importance of this vital component, you can take proactive measures towards maintaining optimal engine performance.

Signs Of Oil Pressure Sensor Issues

If you notice a sudden fluctuation in oil pressure or the oil pressure warning light illuminates on your dashboard, it may indicate a potential issue with the oil pressure sensor. To check the oil pressure sensor, you can use a manual pressure gauge to compare readings or conduct a visual inspection for signs of damage or leaks.

Regular maintenance of the sensor is crucial to ensure accurate oil pressure readings.

Dashboard Warning Lights

When dashboard lights illuminate, engine issues may be present.

Unusual Engine Noises

Grinding or ticking noises indicate potential oil pressure sensor problems.

Low Oil Pressure Reading

Low oil pressure readings on the gauge signal sensor malfunction.

Steps To Check Oil Pressure Sensor

Gathering the necessary tools before checking the oil pressure sensor ensures a smooth process. Make sure to have the following items ready:

Gather Necessary Tools

- Wrench set

- Mechanical gauge or diagnostic tool

- Safety goggles

- Work gloves

Locate The Oil Pressure Sensor

Find the oil pressure sensor usually located near the engine block or oil filter housing.

Inspect For Leaks Or Damage

- Examine the sensor for any signs of leaks or physical damage.

- If any issues are detected, consider replacing the sensor.

Use A Mechanical Gauge For Manual Testing

To manually check the oil pressure sensor, connect the mechanical gauge to the sensor port.

Use A Diagnostic Tool For Electronic Testing

For electronic testing, use a diagnostic tool to read the oil pressure sensor data accurately.

Credit: m.youtube.com

Common Problems And Solutions

This section discusses the common problems encountered when checking the oil pressure sensor and provides practical solutions to resolve them. By identifying and addressing these issues promptly, you can ensure that your oil pressure sensor functions optimally, preventing potential engine damage.

Clogs Or Blockages

A common issue with oil pressure sensors is clogs or blockages that prevent accurate monitoring of the oil pressure. Over time, debris, sludge, or varnish can accumulate in the sensor, obstructing the flow of oil and affecting its performance.

To address this problem, it is recommended to:

- Remove the oil pressure sensor using the appropriate tools.

- Clean the sensor thoroughly, ensuring all debris and obstructions are removed.

- Inspect the surrounding area for any signs of clogs or blockages and clean if necessary.

- Reinstall the oil pressure sensor and ensure it is properly secured.

Regular maintenance, such as changing the engine oil and filter at recommended intervals, can help prevent clogs or blockages from occurring and prolong the lifespan of your oil pressure sensor.

Faulty Wiring

Faulty wiring is another common problem that can lead to inaccurate readings or complete failure of the oil pressure sensor. Wiring issues may include loose connections, frayed wires, or damaged connectors.

To troubleshoot and resolve issues related to faulty wiring:

- Inspect the wiring connections and ensure they are securely fastened.

- Check for any signs of damage or wear on the wires and connectors.

- Repair or replace any faulty wiring components found.

- Test the oil pressure sensor after fixing the wiring to verify if the problem is resolved.

It is crucial to address wiring problems promptly to maintain the accuracy and reliability of your oil pressure sensor.

Sensor Replacement

In some cases, the oil pressure sensor may be beyond repair or no longer functioning correctly despite attempts to rectify the issues mentioned above. When this happens, it may be necessary to replace the sensor entirely.

To replace the oil pressure sensor:

- Consult your vehicle’s manual or seek professional assistance for the specific steps required.

- Choose a suitable replacement sensor that matches the specifications of your vehicle.

- Remove the old sensor carefully, following the recommended procedures.

- Install the new sensor, ensuring proper alignment and connection.

After the replacement, it is advisable to test the new oil pressure sensor to confirm that it is functioning correctly.

By addressing common problems associated with the oil pressure sensor, such as clogs or blockages, faulty wiring, and sensor replacement, you can maintain the reliability of this crucial component in your vehicle’s engine system.

Importance Of Regular Maintenance

Regular maintenance of your vehicle is crucial for ensuring its longevity and optimal performance. Among various components that require constant checking, the oil pressure sensor holds significant importance. By regularly monitoring this sensor, you can ensure that your vehicle’s engine is functioning smoothly and efficiently.

Checking Oil Pressure Sensor As Part Of Routine Maintenance

As part of routine maintenance, it is imperative to regularly check the oil pressure sensor of your vehicle. The sensor plays a vital role in monitoring the oil pressure within the engine. Low oil pressure can lead to engine damage and decreased performance.

- Inspect the oil pressure sensor for any physical damage or signs of oil leakage.

- Use a pressure gauge to measure the actual oil pressure and compare it with the manufacturer’s recommended levels.

- Ensure that the sensor is sending accurate signals to the engine control unit by conducting a diagnostic test using a professional scanning tool.

Seeking Professional Assistance When In Doubt

If you are unsure about the condition of your oil pressure sensor or lack the necessary tools and expertise, it is prudent to seek professional assistance. A qualified mechanic can conduct a comprehensive inspection and diagnose any underlying issues with the sensor, ensuring the optimal functioning of your vehicle’s engine.

Credit: www.linkedin.com

Credit: www.freeasestudyguides.com

Frequently Asked Questions On How To Check Oil Pressure Sensor

How Do You Test An Oil Pressure Sensor?

To test an oil pressure sensor, you can use a pressure gauge connected to the sensor’s port. Start the engine and observe the gauge reading. Compare it to the manufacturer’s specifications to determine if the sensor is functioning correctly.

How Do I Know If My Low Oil Pressure Sensor Is Bad?

To know if your low oil pressure sensor is bad, watch for the check engine light or erratic oil pressure readings.

How Do You Manually Check Oil Pressure?

To manually check oil pressure, start the engine, let it warm up, then shut it off. Remove the oil pressure sending unit and connect a gauge. Start the engine again to check the oil pressure reading on the gauge.

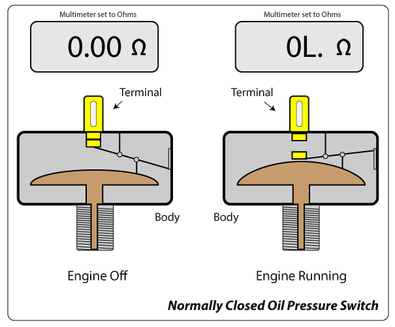

How Do You Test A Pressure Sensor With A Multimeter?

To test a pressure sensor with a multimeter, follow these steps: 1. Turn off power and disconnect the sensor. 2. Set the multimeter to measure resistance. 3. Connect the multimeter’s leads to the sensor’s terminals. 4. Apply varying pressure and observe the resistance change on the multimeter.

5. Compare the readings with the sensor’s specifications to determine its functionality.

How Do I Know If My Oil Pressure Sensor Is Bad?

The most common signs include flickering oil pressure gauge, low oil pressure warning light, or erratic readings.

What Causes A Faulty Oil Pressure Sensor?

A faulty sensor can be caused by oil leaks, electrical issues, or sensor damage from debris.

Can A Bad Oil Pressure Sensor Cause Engine Damage?

Yes, a bad sensor may result in low oil pressure, potentially leading to engine damage if not addressed.

Conclusion

To sum up, checking the oil pressure sensor is an essential task in maintaining the health of your vehicle. By following the steps mentioned in this blog post, you can easily check the oil pressure sensor yourself, ensuring that your engine is functioning optimally.

Regularly monitoring the oil pressure sensor can help detect any potential issues early on and prevent serious damage to your vehicle. Remember, it’s always better to be proactive in maintaining your car’s performance and longevity.