How Do You Check Hydraulic Fluid On A Bobcat

In the realm of heavy machinery maintenance, it is essential to regularly assess and maintain hydraulic fluid levels. Hydraulic fluid serves as a vital component in the operation of various mechanical systems, including Bobcat equipment. This article aims to provide a concise and informative guide on how to check hydraulic fluid levels on a Bobcat, ensuring optimal performance and longevity of the machine. By adhering to a systematic approach outlined within this article, users can effectively gauge hydraulic fluid levels while minimizing potential risks associated with inadequate or excessive fluid levels. Throughout this guide, readers will be introduced to step-by-step instructions that are objective and impersonal in nature, eliminating personal pronouns from the text. Additionally, technical terminology appropriate for an audience seeking understanding will be employed to enhance clarity and comprehension.

Gather the necessary tools and equipment

To begin the process of checking hydraulic fluid on a bobcat, it is important to gather the necessary tools and equipment. Regular checks of hydraulic fluid are essential for maintaining optimal performance and preventing potential damage to the machine. By inspecting the fluid levels, operators can identify any issues early on and take appropriate action.

Before starting, make sure you have a clean cloth or rag to wipe off any dirt or debris from the reservoir cap. This will prevent contamination when opening it. Additionally, have a flashlight handy if necessary to improve visibility in dimly lit areas.

It is also helpful to familiarize yourself with common signs of low hydraulic fluid levels. These may include decreased functionality of hydraulic components such as slower movements or weaker lifting capabilities. Unusual noises like grinding or whining during operation can also indicate low fluid levels.

Having these tools readily available ensures efficiency during the inspection process. With the necessary supplies gathered, you can now proceed to locate the hydraulic fluid reservoir on your bobcat without delay.

Locate the hydraulic fluid reservoir on your Bobcat

The location of the reservoir for the hydraulic fluid in a Bobcat can be easily identified. It is typically located near the engine compartment or on one side of the machine, depending on the model. To locate it, follow these steps:

- Look for a metal or plastic tank with a cap that has hydraulic symbols or labels on it.

- Check your Bobcat’s owner manual for specific instructions and diagrams, as different models may have variations in their design.

- If you are unable to find it, consult with a qualified technician or contact Bobcat customer support for assistance.

Inspecting hydraulic fluid levels is an essential part of maintenance. Ensure that the machine is turned off and parked on level ground before inspecting the fluid level. Use a dipstick or sight glass, if provided, to check the fluid level against the recommended range indicated by markings.

Identifying signs of hydraulic fluid contamination is also crucial. Look for any discoloration (such as milky appearance) or presence of debris in the fluid. These signs may indicate water intrusion or other contaminants, which can affect performance and reliability.

After inspecting the hydraulic fluid levels and identifying any signs of contamination, it is important to clean the area around the reservoir to prevent dirt or debris from entering when opening it up.

Clean the area around the reservoir

Cleaning the area surrounding the reservoir helps prevent the entry of dirt and debris when accessing it. When checking hydraulic fluid on a Bobcat, it is important to take certain precautions to ensure accurate results and maintain proper hydraulic fluid levels. By keeping the area around the reservoir clean, any potential contaminants that could enter during the process are minimized, reducing the risk of damage to the system.

Before starting, it is recommended to turn off the engine and allow it to cool down for a few minutes. This will help avoid any accidental contact with hot surfaces and minimize potential injuries. Once cooled down, locate the hydraulic fluid reservoir on your Bobcat. It is typically located near or on top of the engine compartment.

To clean this area effectively, use a soft cloth or brush to remove any loose dirt or debris around the reservoir cap and its surrounding areas. Be careful not to drop any foreign objects into the reservoir while cleaning. Ensuring cleanliness will facilitate easier access during subsequent steps.

By maintaining cleanliness around the reservoir, you can proceed confidently with removing the reservoir cap and checking the fluid level without worrying about contaminating or damaging internal components of your Bobcat’s hydraulic system.

Remove the reservoir cap and check the fluid level

After cleaning the area around the reservoir, the next step involves removing the reservoir cap to examine and assess the fluid level. This is an essential part of regular maintenance as it allows operators to ensure that the hydraulic system is functioning optimally. Checking hydraulic fluid regularly is crucial for several reasons.

Firstly, maintaining a proper fluid level ensures that there is enough hydraulic fluid to lubricate and cool the system components effectively. Insufficient fluid can lead to increased friction and heat, which may result in premature wear and tear on vital parts. Secondly, having an adequate amount of hydraulic fluid helps maintain consistent pressure within the system, allowing for smooth operation of various functions such as lifting and digging.

To check the hydraulic fluid level accurately, follow these steps:

- Remove the reservoir cap carefully.

- Wipe off any debris or dirt from the dipstick.

- Insert the dipstick into the reservoir until it touches bottom.

- Remove it again and observe where the fluid level reaches on the dipstick.

- If it falls below or near minimum level: add hydraulic fluid until it reaches optimum levels.

- If it exceeds maximum capacity: drain some fluid out until it reaches optimal levels.

By regularly checking and maintaining proper hydraulic fluid levels, operators can ensure smooth machine operation while minimizing potential damage caused by inadequate lubrication or excessive pressure. In case the fluid level is insufficient, adding hydraulic fluid becomes necessary to prevent any adverse effects on Bobcat’s performance.

Add hydraulic fluid if necessary

To maintain optimal machine performance, it is crucial to address the hydraulic fluid level if necessary. One important step in this process is to add hydraulic fluid when needed. Before adding hydraulic fluid, it is essential to first check the hydraulic levels. This can be done by removing the reservoir cap and visually inspecting the fluid level.

When checking the hydraulic levels, it is important to ensure that the machine is on a flat surface and that all attachments are lowered. This allows for an accurate reading of the fluid level. If the fluid level appears low or below the recommended range, it indicates that additional hydraulic fluid needs to be added.

To add hydraulic fluid, locate the fill port on top of the reservoir and remove any debris or dirt around it. Slowly pour in clean hydraulic oil until it reaches the appropriate level indicated on the reservoir or according to manufacturer’s guidelines.

Once sufficient hydraulic fluid has been added, securely replace the reservoir cap. This ensures proper sealing and prevents any leakage during operation. By following these steps, operators can ensure that their Bobcat machines have adequate hydraulic fluid levels for optimal performance and longevity.

Securely replace the reservoir cap

Replacing the reservoir cap securely is essential for maintaining a reliable seal and preventing any potential leakage, ensuring smooth operation and instilling confidence in the longevity of the machine’s performance. A loose or improperly fitted cap can lead to fluid loss, which not only compromises the hydraulic system’s efficiency but also poses safety risks. To emphasize the significance of securing the reservoir cap, consider the following table:

| Potential Consequences of Not Securing Reservoir Cap | Measures to Prevent |

|---|---|

| Increased risk of fluid contamination | Ensure proper alignment before tightening |

| Loss of hydraulic pressure | Use torque specifications provided by manufacturer |

| Impaired equipment performance | Regularly inspect and replace damaged caps |

By replacing the cap securely, operators prevent these undesirable consequences from occurring. Moreover, it allows them to double-check for any leaks or abnormalities that could indicate further issues with the hydraulic system. Ensuring a tight seal helps maintain optimal hydraulic fluid levels and prevents contaminants from entering the system, thus maximizing operational efficiency and minimizing maintenance requirements.

Double-check for any leaks or abnormalities

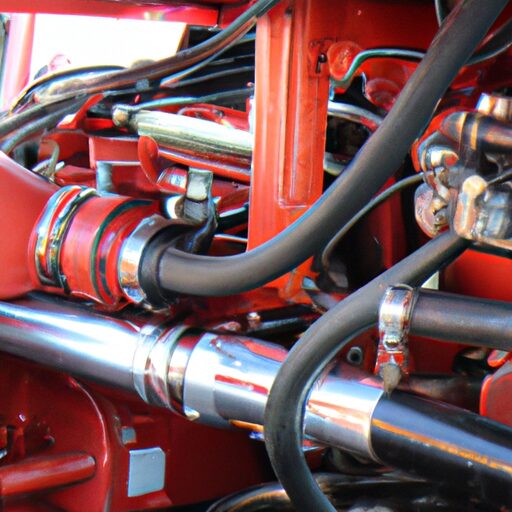

After securely replacing the reservoir cap, it is crucial to double-check for any leaks or abnormalities in order to ensure the proper functioning of the hydraulic system on a Bobcat. This step is essential as any leaks or damage can lead to decreased performance and potential safety hazards.

When checking for leaks, it is important to inspect all connections and fittings thoroughly. Additionally, visually examining the hydraulic hoses for any signs of damage such as cracks, abrasions, or bulges is crucial. Any damaged hoses should be replaced immediately to prevent further issues.

To effectively check for hydraulic fluid contamination, the following steps should be followed:

- Visually inspect the color and consistency of the hydraulic fluid. It should appear clean and free from any debris or contaminants.

- Use a sample bottle to collect a small amount of fluid from different locations within the system.

- Inspect the collected samples under bright light for signs of contamination such as discoloration or particles floating in the fluid.

- If any contamination is detected, it may indicate a problem with filters or seals that need attention.

By carefully conducting these checks, operators can ensure that their Bobcat’s hydraulic system remains in optimal condition, reducing downtime and potential costly repairs.

Frequently Asked Questions

How often should I check the hydraulic fluid on my Bobcat?

Regularly checking the hydraulic fluid on a bobcat is crucial. Neglecting this maintenance can lead to issues such as decreased performance, increased wear and tear on components, and even potential damage to the hydraulic system. It is recommended to change the hydraulic fluid based on the manufacturer’s guidelines.

Can I use any type of hydraulic fluid for my Bobcat?

Using improper hydraulic fluid for my bobcat can cause serious damage. It is important to use the recommended hydraulic fluid specified by the manufacturer to ensure optimal performance and avoid potential issues.

What are the common signs of low hydraulic fluid levels in a Bobcat?

Common signs of low hydraulic fluid levels in a bobcat include decreased performance, sluggish operation, and unusual noises. To refill the hydraulic fluid, locate the reservoir tank, open the cap, and pour in the appropriate fluid specified by the manufacturer.

Are there any specific safety precautions I should take while checking the hydraulic fluid on my Bobcat?

To ensure safety while checking hydraulic fluid on a bobcat, it is essential to follow proper handling procedures. This includes wearing personal protective equipment, such as gloves and goggles, and being cautious of hot surfaces or moving parts.

Is it normal for the hydraulic fluid level to decrease over time, or could there be a potential issue with my Bobcat if this occurs?

A decrease in hydraulic fluid level over time is not normal and may indicate a potential issue with the bobcat. Regular maintenance of the bobcat’s hydraulic fluid level is essential to ensure proper functioning and prevent damage to the system.

Conclusion

In conclusion, checking the hydraulic fluid on a Bobcat requires gathering the necessary tools and equipment, locating the reservoir, cleaning the area around it, removing the cap to check the fluid level, adding more if needed, securely replacing the cap, and double-checking for leaks or abnormalities. By following these steps diligently, one can ensure proper maintenance of their Bobcat machinery. Remember to always prioritize safety and refer to the manufacturer’s guidelines for accurate information.