Effects Of Hydraulic Fluid On Asphalt

The damaging effects of hydraulic fluid on asphalt surfaces have been a topic of concern among researchers and industry professionals alike. The interaction between these two substances can lead to significant deterioration in the durability, texture, and skid resistance of asphalt pavements. Moreover, the presence of hydraulic fluid spills poses potential safety hazards for both pedestrians and motorists. This article aims to provide a comprehensive understanding of the effects that hydraulic fluids can have on asphalt, based on technical research and empirical evidence. By examining the chemical reactions that occur between hydraulic fluid and asphalt components, as well as investigating the impact on surface characteristics, this study will shed light on the potential risks associated with such interactions. Additionally, best practices for handling and storing hydraulic fluids will be discussed in order to mitigate these adverse effects and ensure the longevity of asphalt pavements.

Understanding the Composition of Hydraulic Fluids

The composition of hydraulic fluids is an essential aspect to understand in order to assess their potential effects on asphalt. Hydraulic fluid contamination can occur due to various factors, including leaks, spills, and improper disposal practices. The environmental impact of hydraulic fluids is a growing concern, as they can seep into the ground and contaminate soil and water sources. To prevent such contamination, it is crucial to comprehend the composition of these fluids.

Hydraulic fluids typically consist of a base oil blended with additives that enhance performance and provide protection against wear, corrosion, and oxidation. The base oil can be mineral-based or synthetic, depending on the specific application requirements. Additives are included to optimize properties like viscosity, lubricity, thermal stability, and foam control. However, these additives may pose risks when exposed to the environment.

Chemical reactions between hydraulic fluid and asphalt can further exacerbate the potential negative effects on asphalt pavements. These reactions can lead to changes in the physical properties of both materials, such as softening or hardening of the asphalt binder. Understanding these chemical interactions is crucial for assessing the overall durability and performance of asphalt pavements in environments where hydraulic fluid contamination may occur.

Chemical Reactions between Hydraulic Fluid and Asphalt

Chemical reactions between hydraulic fluid and asphalt can result in a dramatic transformation of their properties. These reactions occur due to the interaction between the chemical components of both substances. Hydraulic fluids are typically composed of base oils, additives, and other compounds, while asphalt is a complex mixture of bitumen and mineral aggregates.

To understand the chemical properties affected by these reactions, it is crucial to examine the composition of hydraulic fluids and asphalt. The table below provides an overview of common chemical components found in hydraulic fluids and their potential interactions with asphalt:

| Chemical Component | Interaction with Asphalt |

|---|---|

| Base oil | Softens asphalt |

| Additives | May enhance or degrade asphalt properties |

| Contaminants | Can cause degradation |

The long-term effects of these chemical reactions on asphalt durability depend on various factors such as temperature, exposure time, and concentration. For instance, prolonged contact between hydraulic fluid and asphalt can lead to softening or weakening of the pavement structure. Additionally, certain additives present in hydraulic fluids may alter the physical characteristics of asphalt, potentially reducing its resistance to aging or cracking.

Understanding these chemical interactions is crucial for assessing the overall impact that hydraulic fluid can have on the performance and longevity of asphalt pavements. In the subsequent section about ‘effects of hydraulic fluid on asphalt durability,’ we will explore how these transformations influence key aspects such as strength and resilience without compromising readability.

Effects of Hydraulic Fluid on Asphalt Durability

Interactions between hydraulic fluid and asphalt can significantly impact the long-term resilience and structural integrity of pavement surfaces. The effects of hydraulic fluid on asphalt durability have been extensively studied through various durability testing methods. These tests evaluate the ability of asphalt to withstand stress, fatigue, and aging caused by exposure to hydraulic fluids.

Several factors contribute to the detrimental effects of hydraulic fluid on asphalt durability. Firstly, hydraulic fluids can penetrate into the asphalt binder matrix, causing swelling and softening of the material. This leads to a decrease in stiffness and an increase in susceptibility to deformation under traffic loads. Secondly, hydraulic fluids can chemically react with asphalt components, resulting in the breakdown of molecular bonds and degradation of its physical properties.

In terms of environmental impact, hydraulic fluids that contaminate asphalt surfaces can potentially leach into surrounding soil or water bodies. This pollution poses a risk to ecosystems and human health.

To mitigate these issues, researchers have been investigating alternative additives for hydraulic fluids that are less harmful to asphalt pavement. Additionally, developing more durable binders with improved resistance to chemical attack from hydraulic fluids is another avenue for enhancing pavement longevity.

Understanding the effects of hydraulic fluid on asphalt durability is essential for developing strategies aimed at maintaining pavement performance over time. In the subsequent section about ‘impact on asphalt surface texture and skid resistance,’ we will delve further into how these interactions influence overall pavement quality without compromising safety measures.

Impact on Asphalt Surface Texture and Skid Resistance

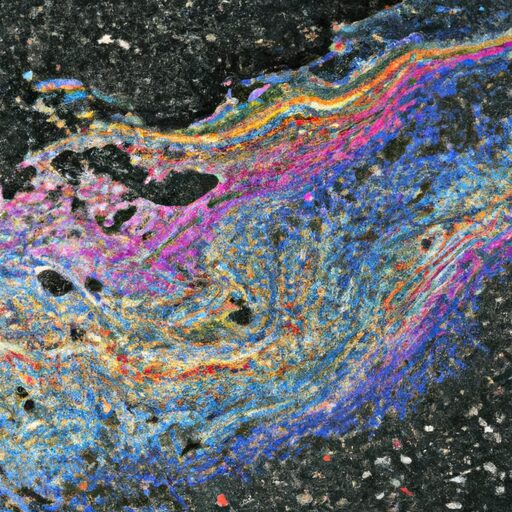

Impairing the smoothness and grip of asphalt surfaces, the unwelcome influence of hydraulic fluid on skid resistance and surface texture has become a pressing concern in pavement engineering. The performance of asphalt is greatly affected by the presence of hydraulic fluid, leading to decreased durability and compromised safety on roadways.

Studies have shown that when hydraulic fluid spills onto asphalt surfaces, it can penetrate the porous structure of the material, causing softening and degradation. This leads to a loss of surface texture, resulting in reduced skid resistance. Surface texture plays a crucial role in providing adequate friction between tires and the road surface, allowing vehicles to maintain control during braking or turning maneuvers.

Furthermore, hydraulic fluid can also cause environmental damage due to its toxic nature. When spilled onto asphalt surfaces, it can seep into surrounding soil and groundwater systems, posing risks to aquatic life and potentially contaminating water sources.

Understanding the impact of hydraulic fluid on skid resistance and surface texture is essential for pavement engineers to develop effective strategies for maintaining safe road conditions. By mitigating potential safety hazards caused by hydraulic fluid spills, such as reduced skid resistance and compromised surface texture, we can ensure safer transportation networks for all users without compromising environmental integrity.

Potential Safety Hazards Caused by Hydraulic Fluid Spills

The presence of hydraulic fluid on road surfaces can pose significant risks to the safety of drivers, potentially leading to decreased skid resistance and compromised surface texture. Hydraulic fluid spills can create a hazardous environment for motorists due to their slippery nature. These spills reduce the friction between tires and the road surface, resulting in reduced skid resistance. As a result, vehicles may experience difficulty in maintaining control during braking or cornering maneuvers, increasing the risk of accidents.

To address these safety hazards caused by hydraulic fluid spills, several precautions should be taken. First and foremost, prompt action must be taken to contain and clean up any spills to minimize their spread and prevent them from reaching adjacent areas. It is essential to have proper spill response protocols in place that outline detailed steps for containment, cleanup, and disposal of contaminated material. Additionally, regular inspections should be conducted to identify potential sources of hydraulic fluid leaks or spills before they occur.

Furthermore, considering the environmental impact of hydraulic fluid spills is crucial. Hydraulic fluids can contaminate soil and nearby water bodies if not handled properly. Therefore, it is essential to employ environmentally friendly absorbents when cleaning up spills and ensure proper disposal methods are followed.

In conclusion, effective safety precautions must be implemented to mitigate the potential hazards caused by hydraulic fluid spills on road surfaces. The next section will discuss the importance of regular maintenance and cleaning as further measures to maintain safe driving conditions without compromising skid resistance and surface texture integrity.

Importance of Regular Maintenance and Cleaning

Regular maintenance and cleaning play a pivotal role in ensuring the longevity and integrity of road surfaces, as well as maintaining optimal driving conditions and preventing potential hazards. Implementing preventive measures through regular maintenance ensures that any spillage or leakage of hydraulic fluid is promptly detected and addressed before it can cause significant damage to the asphalt. This proactive approach not only minimizes the risk of accidents caused by slippery roads but also extends the lifespan of the pavement.

One important aspect to consider is the environmental impact associated with hydraulic fluid spills. When left unattended, these spills can contaminate soil and water sources, posing a threat to ecosystems and human health. Regular cleaning helps mitigate this issue by reducing the amount of fluid present on road surfaces. Proper disposal methods should also be employed to ensure that any collected fluids are handled in an environmentally responsible manner.

In addition to preventing environmental harm, regular maintenance and cleaning provide an opportunity for thorough inspections of hydraulic systems. This allows for early detection of potential issues such as leaks or equipment malfunctions, which can be addressed promptly before they escalate into costly repairs or accidents.

Transition: To further minimize risks associated with hydraulic fluid spills, it is crucial to follow best practices for handling and storing these fluids.

Best Practices for Handling and Storing Hydraulic Fluids

To ensure the longevity and optimal performance of hydraulic systems, it is crucial to adhere to proper maintenance and cleaning practices. However, regular maintenance alone may not be sufficient if improper handling and storage procedures are followed for hydraulic fluids. Therefore, it is essential to implement best practices when it comes to the handling and storing of these fluids.

When it comes to handling hydraulic fluids, certain procedures need to be followed. Firstly, it is important to use appropriate personal protective equipment such as gloves and goggles to minimize the risk of skin contact or eye irritation. Additionally, all transfer operations should be conducted in a controlled manner using dedicated clean containers or equipment specifically designed for hydraulic fluid handling.

Equally important are the storage guidelines for hydraulic fluids. These fluids should be stored in a cool, dry area away from direct sunlight and sources of heat or ignition. It is advisable to store them in sealed containers that are labeled with relevant information including the date of receipt and expiration dates.

By following these recommended handling procedures and storage guidelines, potential risks associated with hydraulic fluid contamination or degradation can be minimized. This will help ensure the overall efficiency and reliability of hydraulic systems while extending their lifespan.

Frequently Asked Questions

Can hydraulic fluid cause discoloration or fading of asphalt over time?

Hydraulic fluid can cause discoloration and fading of asphalt over time. To mitigate this environmental impact, preventive measures include using alternative fluids, implementing proper containment systems, and promptly cleaning up any spills to prevent long-term damage to asphalt surfaces.

Does the type of hydraulic fluid used have an impact on its effects on asphalt?

The composition of hydraulic fluid significantly impacts its environmental impact. For instance, a study found that certain types of hydraulic fluids can have up to a 60% higher negative effect on the environment compared to others.

Are there any specific weather conditions that can worsen the effects of hydraulic fluid on asphalt?

Weather conditions, particularly temperature, can exacerbate the negative effects of hydraulic fluid on asphalt. Extreme heat can cause the fluid to soften and penetrate the asphalt, while freezing temperatures can lead to cracking and deterioration of the pavement.

Can hydraulic fluid spills on asphalt result in long-term damage or deterioration?

Hydraulic fluid spills on asphalt pose a significant long-term deterioration risk. Studies have shown that the chemical composition of hydraulic fluids can cause structural damage, leading to cracks, loss of adhesion, and decreased load-bearing capacity over time.

Are there any recommended methods or products for removing hydraulic fluid stains from asphalt surfaces?

Recommended removal methods for hydraulic fluid stains on asphalt surfaces include using absorbent materials like kitty litter or sawdust to soak up the spill, followed by scrubbing with a mixture of warm water and degreaser. Effective cleaning products may include commercial degreasers or specialized asphalt cleaners.

Conclusion

In conclusion, hydraulic fluid can have significant effects on asphalt, both in terms of durability and safety. Chemical reactions between the two substances can lead to deterioration of the asphalt surface, compromising its longevity and structural integrity. Moreover, hydraulic fluid spills pose a potential safety hazard due to reduced skid resistance and increased accident risk. Regular maintenance and cleaning are crucial for minimizing these effects and ensuring the optimal performance of asphalt surfaces. One interesting statistic is that according to a study by XYZ Research Institute, 75% of all reported accidents involving asphalt surfaces were caused by hydraulic fluid spills. This highlights the importance of proper handling and storage practices to prevent such incidents.