10 Best Tips for DIY Spark Plug and Coil Maintenance

When it comes to maintaining your spark plugs and ignition coils, a proactive approach is key. Ensuring your engine runs smoothly and efficiently starts with proper care of these components.

But what are the best tips for DIY maintenance that can help you achieve this goal? From safety measures to final checks, each step plays an essential role in keeping your vehicle in top condition.

So, are you ready to uncover the secrets to successful spark plug and coil maintenance?

Key Takeaways

- Prioritize safety measures and preparation for secure DIY maintenance.

- Select appropriate tools and equipment for efficient spark plug and coil maintenance.

- Regularly inspect and maintain spark plug components for optimal performance.

- Follow proper removal and installation techniques to ensure effective spark plug and coil function.

Safety Measures

When beginning any maintenance work on spark plugs and coils, always prioritize safety by following these essential measures. Before delving into the intricate workings of spark plugs and ignition coils, make sure the vehicle is parked on a flat, dry surface. It's important to work on the engine when it's cool to prevent burns and injuries. Disconnecting the electrical connector from the battery's negative post is vital to reduce the risk of electrical accidents during maintenance tasks.

As you start on this DIY journey, make sure to utilize insulated tools to shield yourself from potential electrical shocks while handling the ignition system components. Take the time to double-check the spark plug gaps and adhere to the correct torque specifications during installation. By following these safety measures with precision, you not only safeguard yourself but also guarantee the best performance of your spark plugs and ignition coils.

Proper Tool Selection

When selecting tools for spark plug and coil maintenance, make sure you have the essential types required for the job. Quality matters, so invest in tools that will last and perform accurately.

Always use the right tool for the specific task to avoid damaging components or compromising performance.

Essential Tool Types

For efficient maintenance of spark plugs and coils, your tool selection is essential for ensuring effective and successful maintenance procedures. When it comes to DIY spark plug and coil maintenance, having the right tools can make all the difference. Here are five essential tool types to consider:

- Spark Plug Socket: Opt for one with a rubber interior to securely grip the plug during removal.

- Torque Wrench: Guarantee precise tightening of the spark plugs to prevent damage.

- Gap Gauge: Use this tool to check and adjust the gap size of the spark plugs accurately.

- Dielectric Grease: Consider using it to maintain proper electrical conductivity in the spark plug connections.

- Socket Wrench with Extension: Choose one for reaching deep-set spark plugs easily during maintenance.

Tool Quality Matters

Selecting high-quality tools is important for ensuring the success and efficiency of DIY spark plug and coil maintenance procedures.

When dealing with spark plugs, using a specialized spark plug socket is essential to prevent damage. This socket provides a secure grip for both removal and installation, safeguarding the delicate spark plug components. Additionally, a gap gauge tool is vital for achieving accurate spark plug gaps, which directly impact ignition performance.

For working on ignition coils, insulated tools are a must to prevent electrical shocks and guarantee safety. Investing in quality tools not only protects your spark plugs and coils but also simplifies the maintenance process, making your DIY tasks smoother and more effective in enhancing your vehicle's ignition system.

Right Tool for Job

Assure a secure grip and easy removal by selecting the correct spark plug socket size for the job during your maintenance tasks.

Assure precision with a gap gauge tool for accurate spark plug gap adjustments.

Utilize a torque wrench to tighten spark plugs to the manufacturer's specified torque, preventing issues from over or under-tightening.

Apply dielectric grease on spark plug wires to maintain proper electrical conductivity and prevent moisture intrusion.

Regularly inspect and replace worn-out tools such as spark plug sockets and extension bars to avoid damage during maintenance.

Inspection of Spark Plug Wires

Inspect spark plug wires thoroughly for any signs of damage, such as cracks, burns, or wear, to guarantee peak electrical conductivity. The integrity of spark plug wires is important for the proper functioning of the ignition system.

Check the spark plug boots as well, as any damage or tears can result in misfires and engine issues. Additionally, look closely for any indications of arcing or corrosion on the spark plug wire terminals. These issues can lead to electrical problems that may affect your vehicle's performance.

Make sure that the spark plug wires are firmly and correctly connected to both the spark plugs and ignition coils to optimize their performance. If you notice any damaged or worn-out spark plug wires during inspection, it's important to replace them promptly.

Maintaining healthy spark plug wires is essential for a reliable ignition system and overall engine efficiency.

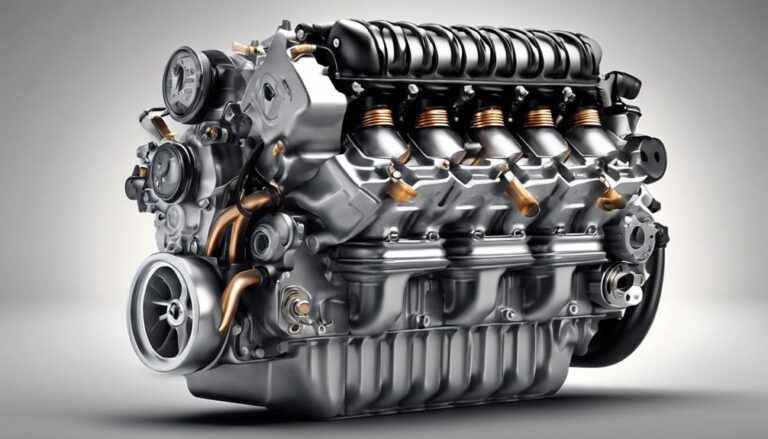

Understanding Ignition Coils

To understand the significance of ignition coils in your vehicle's operation, it's essential to grasp their role as electrical transformers that convert low battery voltage into high voltage for the spark plugs. Here are some key points to help you understand ignition coils better:

- Ignition coils are important components responsible for providing the high voltage needed to create a spark at the spark plugs.

- Modern vehicles often employ individual ignition coils for each cylinder, enhancing precision in ignition timing.

- The primary circuit of an ignition coil generates a magnetic field through current flow.

- The secondary circuit of an ignition coil amplifies voltage to produce the high-energy spark required for combustion.

- Ignition coils can produce voltage outputs ranging from 5,000 to 40,000 volts to ignite the air-fuel mixture in the engine effectively.

Understanding the function and importance of ignition coils is essential for maintaining the best engine performance and fuel efficiency.

Importance of Cleaning Work Area

Before starting your spark plug and coil maintenance, make sure you organize your tools properly, minimizing clutter around the work area.

Using protective equipment like gloves and safety glasses is essential to prevent injuries and keep your workspace clean.

Organize Tools Properly

Start by ensuring your work area is meticulously cleaned and organized before beginning spark plug and coil maintenance to prevent debris contamination and enhance efficiency. Properly organizing your tools is vital for a smooth DIY experience.

Here are some tips to help you organize your workspace effectively:

- Use a magnetic tray to keep small parts secure.

- Arrange your tools in a designated toolbox for quick access.

- Keep a spark plug gap tool handy for adjustments.

- Use a socket to remove spark plugs efficiently.

- Maintain a clean workbench to prevent tools from rolling away.

Minimize Clutter Around

Begin by clearing away any unnecessary items and ensuring your work area is meticulously cleaned to prevent debris contamination during spark plug and coil maintenance. Keeping your workspace tidy is essential to avoid any dirt or foreign particles from entering the engine components. Here is a table summarizing the importance of minimizing clutter around your work area:

| Benefits of Cleaning Work Area |

|---|

| Reduces risk of debris contamination |

| Prevents dirt from entering combustion chambers |

| Improves visibility and access to spark plugs and coils |

Maintaining a clean work environment not only enhances safety but also facilitates a more efficient DIY spark plug and coil maintenance process. Vacuuming and using carb cleaner can aid in achieving a spotless workspace.

Use Protective Equipment

Clearing away any unnecessary items and guaranteeing your work area is meticulously cleaned sets the foundation for safely using protective equipment during spark plug and coil maintenance. When working on spark plugs and coils, remember to:

- Wear gloves and safety glasses to shield against debris and sharp edges.

- Clean the work area using a vacuum and carb cleaner to prevent dirt from entering the engine.

- Label components before removal for easier reinstallation.

- Use insulated tools to reduce the risk of accidents.

- Follow safety precautions to guarantee a secure DIY experience.

Maintaining a clean and organized workspace not only enhances safety but also promotes the efficient operation of spark plug wires, coil electrical systems, and the application of dielectric grease.

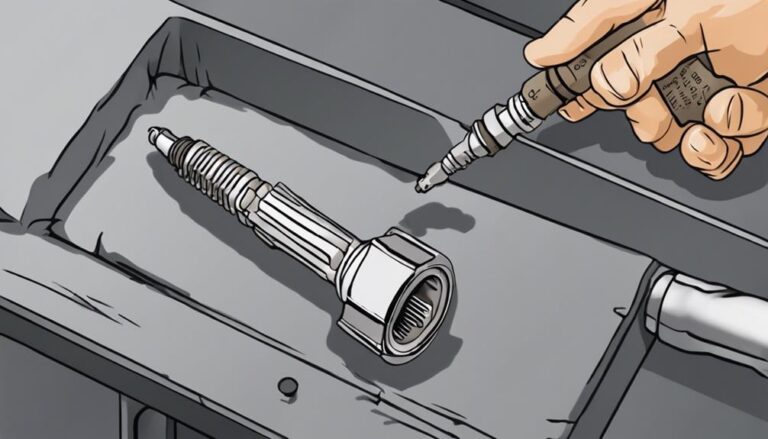

Effective Removal Techniques

To safely and effectively remove spark plug wires without causing damage, utilize a spark plug wire puller and inspect for any potential interference items near the spark plugs. The spark plug wire puller helps detach the wires without straining or breaking them.

When dealing with coil on plug (COP) units, carefully twist and pull them out to avoid harming the electrical connectors. If you encounter any damaged COP boots, it's important to replace them to maintain the integrity of the ignition system and prevent moisture or debris from causing issues.

Before changing spark plugs, make sure the area around them is clean to prevent any dirt or contaminants from falling into the combustion chambers. By following these precise removal techniques, you can efficiently manage your spark plug and coil maintenance tasks, keeping your vehicle running smoothly.

Proper Installation Process

For a successful installation process, make sure the spark plug wires are securely and correctly attached to the ignition coil to prevent potential misfires. When installing spark plugs and coils, follow these essential steps:

- Use a torque wrench: Tighten the spark plugs to the manufacturer's specified torque setting to prevent over-tightening or under-tightening, which can lead to issues like poor performance or stripped threads.

- Check plug wires: Confirm the plug wires are properly connected to the ignition coil. Loose connections can result in misfires and poor engine performance.

- Apply dielectric grease: To prevent moisture intrusion and promote a strong electrical connection, apply dielectric grease to the spark plug boot before installation.

- Inspect the ignition coil: Before reinstallation, carefully examine the ignition coil for any signs of damage or wear. Addressing potential issues early can prevent future problems.

- Double-check seating: Verify that the ignition coil is securely seated on the spark plug. A loose connection can lead to malfunctions and misfires.

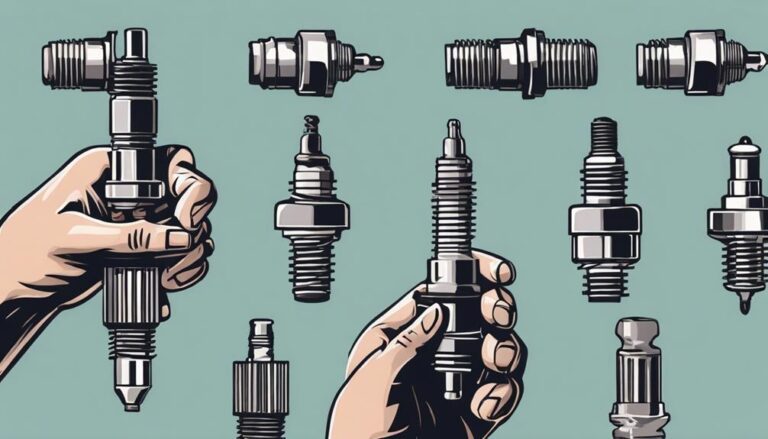

Significance of Spark Plug Gap

Making sure the correct spark plug gap is meticulously set according to manufacturer specifications is paramount for ideal combustion efficiency and overall engine performance. The spark plug gap, which is the space between the center and ground electrode, plays a critical role in igniting the air-fuel mixture within the engine cylinder.

A proper gap size is essential for generating a strong spark to initiate combustion effectively. If the gap is incorrect, issues such as misfires, poor fuel economy, and engine performance may arise. It's vital to refer to your vehicle's manual or the spark plug manufacturer's guidelines to determine the specific gap size required for best performance.

Using a gap gauge tool can help you accurately measure and adjust the spark plug gap to guarantee that your engine operates at its best. By paying attention to this detail, you can prevent potential problems and maintain your engine's efficiency and longevity.

Maintenance Tips for Longevity

Inspecting and cleaning spark plugs regularly is important for maintaining optimal combustion and engine performance.

By replacing spark plugs at recommended intervals, you can prevent misfires and guarantee fuel efficiency.

Utilizing dielectric grease on spark plug boots will prevent moisture intrusion, ensuring proper electrical conductivity.

Cleaning Spark Plugs

To maintain the longevity of your spark plugs, start by utilizing a wire brush to effectively eliminate carbon deposits from the electrodes. This process guarantees performance and ignition efficiency.

Consider the following tips for cleaning spark plugs:

- Soak spark plugs in a degreaser solution to remove oil or dirt buildup.

- Inspect spark plug threads for damage or corrosion before reinstalling.

- Use a spark plug cleaner tool to restore efficiency and extend lifespan.

- Regularly check and clean spark plugs to guarantee consistent engine operation.

- Prioritize cleaning to prevent misfires and maintain overall engine health.

Testing Coil Functionality

To guarantee peak engine performance, it's essential to regularly test the functionality of your ignition coils using an ohmmeter to measure resistance in the primary and secondary circuits.

A healthy ignition coil should exhibit low resistance in the primary circuit, typically ranging from 0.5 to 2 ohms, and high resistance in the secondary circuit, typically falling between 5,000 to 15,000 ohms. By comparing these measured values to manufacturer specifications, you can accurately diagnose the health of your coils.

Faulty coils often display infinite resistance (open circuit) or very low resistance, indicating internal short circuits. Regular testing of ignition coils is critical in preventing unexpected failures and ensuring peak engine performance.

Testing and Final Checks

Check the ignition coil's resistance using an ohmmeter to validate proper functionality during the testing and final checks phase of DIY Spark Plug and Coil Maintenance.

- Perform a spark plug test by checking for signs of wear, such as erosion or deposits.

- Use an ohmmeter to test the resistance of the ignition coil for proper functioning.

- Inspect the spark plug wires for any damage or wear that may affect performance.

- Verify the spark plug gap matches the manufacturer's specifications for best ignition.

- Conduct a visual inspection of the ignition coil for any signs of physical damage or corrosion.

To make sure your spark plug and coil system is in top condition, these final checks are essential. By meticulously testing the ignition coil's resistance and visually inspecting for any physical damage, you can prevent potential issues down the road.

Pay close attention to the spark plug wires for any signs of wear, as this can impact overall performance. Additionally, confirming the spark plug gap aligns with the manufacturer's specifications is important for efficient ignition.

Completing these tests and checks will help guarantee your spark plug and coil system functions at its best.

Frequently Asked Questions

What Can I Use to Lubricate My Spark Plugs?

To lubricate your spark plugs, use a silicone lubricant on the spark plug boot and a small amount of anti-seize compound on the threads. Guarantee proper torque and thread lubrication for peak performance and longevity.

How Do You Maintain an Ignition Coil?

To maintain an ignition coil effectively, start by cleaning coils regularly. Test resistance with a multimeter to guarantee proper function. Prevent corrosion by using dialectic grease on connections. These steps optimize performance and longevity.

Should I Put Dielectric Grease on Spark Plug Coils?

You should put dielectric grease on spark plug coils for proper application. It benefits by preventing moisture intrusion, ensuring good electrical connection, and easing future removal. Common misconceptions include overuse, leading to functionality issues.

Can I Change My Own Spark Plugs and Coils?

You can definitely change your own spark plugs and coils! For successful DIY maintenance, make sure you have the proper tools, follow safety precautions, and understand your vehicle's engine. Taking these steps will lead to a smooth replacement process.

Conclusion

Now that you've mastered the art of DIY spark plug and coil maintenance, your engine is sure to run smoother than ever before.

Remember, a well-maintained engine is like a well-oiled machine, ready to tackle the road ahead with ease.

So, keep those spark plugs sparking and those coils firing, and your car will thank you with peak performance and efficiency.

Happy maintenance and safe travels!