DIY Tips for Brake Caliper Maintenance

Maintaining the integrity of your brake calipers is essential for ensuring smooth stops and safe journeys on the road. When it comes to DIY tips for brake caliper upkeep, there are key practices that can significantly impact the performance of your vehicle's braking system.

From simple inspections to more intricate tasks, understanding how to properly care for your brake calipers can make a substantial difference in your driving experience. By implementing these maintenance techniques, you'll not only enhance your vehicle's safety but also extend the lifespan of crucial components.

Key Takeaways

- Regularly inspect caliper components for smooth operation and signs of wear to ensure proper brake function.

- Replace caliper seals with matching specifications and follow proper installation procedures for optimal performance.

- Keep caliper slides well-lubricated with suitable grease to prevent sticking and ensure even brake pad wear.

- Bleed brake caliper fluid using the correct tools and procedures to eliminate air bubbles and maintain brake efficiency.

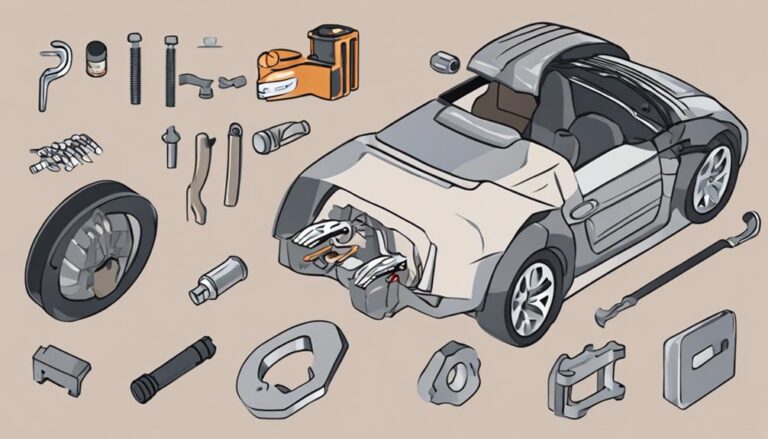

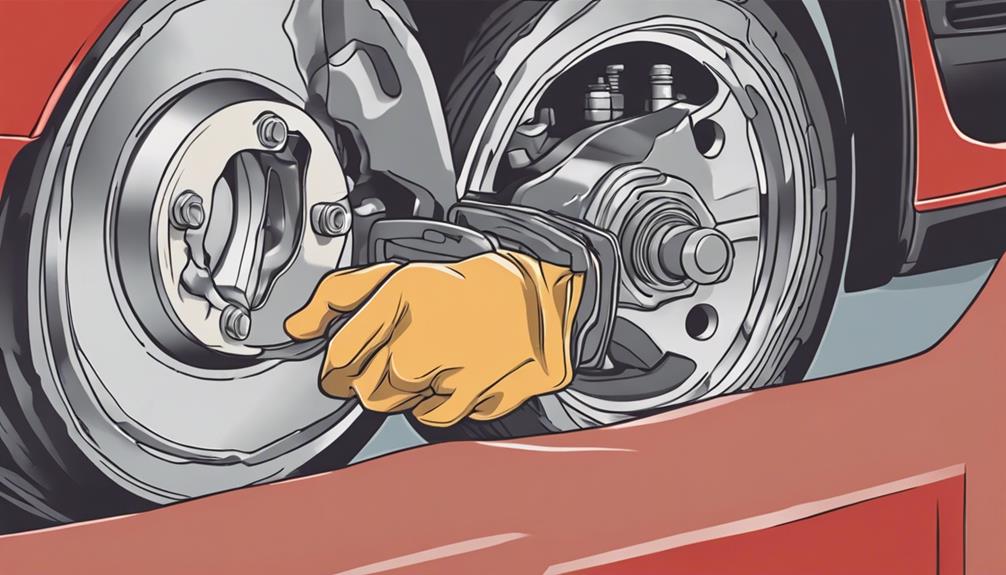

Inspecting Brake Caliper Components

When inspecting brake caliper components, carefully examine the caliper pistons for smooth movement and any signs of corrosion or damage. The caliper piston evaluation is crucial as any irregularities can lead to braking issues. Ensure the pistons move freely within the caliper bore without any sticking or hesitation.

Additionally, inspect the O-rings for wear or damage as they're vital in maintaining a proper seal and preventing brake fluid leaks. Moving on to caliper ear alignment, make sure the caliper ears and bushings are in good condition. Misaligned caliper ears can cause uneven brake pad wear and affect braking performance.

Lastly, be vigilant for any signs of leaking brake fluid around the caliper, as this could indicate potential seal problems. By paying attention to these details, you can ensure your brake caliper components are in optimal condition, promoting safe and efficient braking.

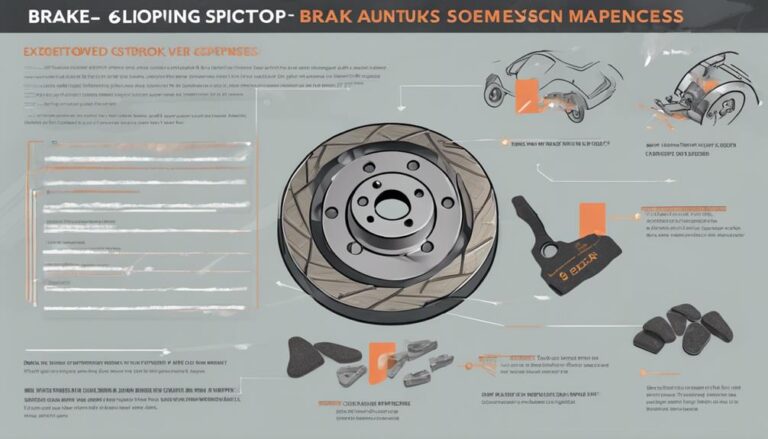

Replacing Brake Caliper Seals

To ensure the continued proper functioning of your brake caliper, replacing the seals is a critical maintenance task that shouldn't be overlooked. Seal quality plays a vital role in preventing brake fluid leakage and maintaining hydraulic pressure. When replacing seals, it's crucial to use ones that match the original specifications to ensure proper fit and function. Before installing new seals, thoroughly clean the caliper to prevent any contamination that could affect their performance.

The installation process of brake caliper seals requires precision and attention to detail. Begin by carefully removing the old seals and cleaning the seal grooves. Next, lubricate the new seals with brake fluid before carefully inserting them into place. Ensure that the seals are properly seated and that there are no twists or kinks that could compromise their effectiveness. Once the new seals are in position, reassemble the caliper following the manufacturer's recommendations.

Properly installed and functioning seals are crucial for safe and effective brake operation. Regularly inspecting and replacing seals as needed will help maintain the overall performance and safety of your braking system.

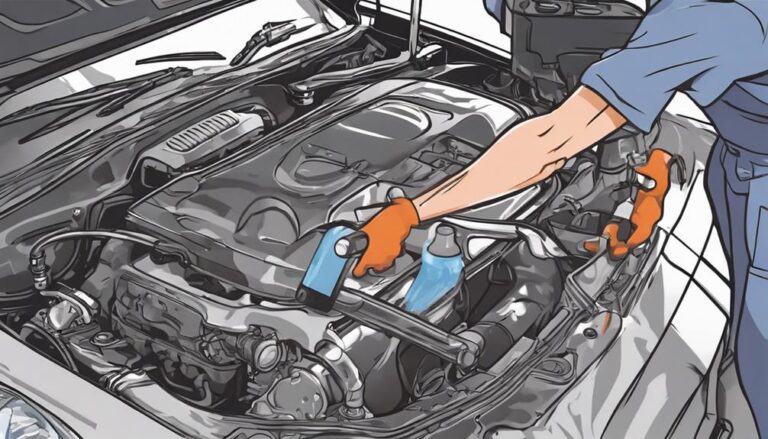

Lubricating Brake Caliper Slides

Proper lubrication of brake caliper slides is essential for maintaining optimal brake performance and functionality. Before applying lubrication, ensure thorough cleaning of excessive brake dust and dirt from the slides.

To prepare the caliper for lubrication, utilize an old brake pad to gently push the piston back into place. Prior to re-lubricating, inspect and clean the caliper pins to guarantee smooth operation.

When applying grease, opt for suitable options like silicone or caliper grease to facilitate the free movement of the slides. Common mistakes during this process include using incorrect lubricants or over-greasing, which can lead to malfunctions and reduced brake efficiency.

Bleeding Brake Caliper Fluid

Begin by ensuring that all necessary tools and equipment for bleeding brake caliper fluid are readily available. You'll need a brake bleeder kit, a suitable container to collect the old fluid, a wrench or socket set, and the correct type of brake fluid recommended by the manufacturer. There are different types of brake fluids, so make sure to use the one specified for your vehicle to avoid any issues.

When bleeding brake caliper fluid, there are two main techniques commonly used: the traditional two-person method and the single-person brake bleeder kit. The traditional method involves one person pumping the brake pedal while another opens and closes the bleeder valve to release air bubbles. The single-person brake bleeder kit utilizes a hand pump to create pressure in the brake system, making it easier for one person to bleed the brakes effectively.

Testing Brake Caliper Operation

Examine the brake caliper's functionality by applying consistent pressure on the pedal to detect any irregular sensations such as sticking or dragging. Listen attentively for any unusual noises like squeaking or grinding while engaging the brakes, as these may point to underlying caliper issues.

To conduct a thorough analysis of brake caliper performance, visually inspect the brake pads for any signs of uneven wear patterns, indicating possible pressure distribution problems from the caliper. Check meticulously for leaks in the caliper vicinity, as any brake fluid leaks can significantly affect the hydraulic functionality of the caliper.

Perform a detailed caliper piston inspection to troubleshoot any potential operational deficiencies. Ensure the caliper moves smoothly and uniformly when the brakes are applied to guarantee proper functioning.

This meticulous brake caliper performance analysis and tuning are essential to maintain optimal braking efficiency and safety on the road.

Frequently Asked Questions

How Do You Maintain Brake Calipers?

To maintain brake calipers, clean slide pins regularly, use appropriate lubricants, and replace worn components like O-rings. Prevent caliper corrosion by inspecting and addressing any sticking pistons. Proper maintenance ensures optimal performance and safety.

What Is the Best Lubricant for Calipers?

When it comes to lubricating your calipers, opt for silicone-based grease for optimal lubricant compatibility. Apply it sparingly on slide pins and rubber components to ensure smooth movement and prevent damage.

What Can I Use to Lubricate My Brake Caliper Piston?

You can use silicone grease to lubricate your brake caliper piston. It is essential for brake caliper boot maintenance, preventing water intrusion and ensuring proper seal function. Apply it carefully for optimal brake system performance.

How Do You Lubricate Brake Pads and Calipers?

To lubricate brake pads and calipers properly, ensure you apply grease or silicone lubricant on pins, brackets, and slide pins. This thin layer prevents corrosion, reduces friction, and noise, ensuring smooth, safe braking and preventing brake squeal.

Conclusion

In conclusion, DIY enthusiasts must prioritize regular maintenance of brake calipers to ensure optimal performance and safety.

By following the outlined tips for inspection, replacement, lubrication, bleeding, and testing, individuals can effectively enhance the longevity and efficiency of their brake system.

Remember, proper maintenance not only saves time and money but also promotes safe driving practices.

So, put these tips into action and see the truth in the theory of maximizing brake caliper performance through proactive maintenance.