Ultimate Fuel Pressure Sensor Replacement Guide

If you need to replace the fuel pressure sensor in your vehicle, follow this straightforward guide.

Importance Of Fuel Pressure Sensor

In this Ultimate Fuel Pressure Sensor Replacement Guide, we cannot stress enough the importance of the fuel pressure sensor in your vehicle. The fuel pressure sensor is a critical component that ensures the optimum performance of your engine and protects it from potential damage. It provides vital information to the engine control unit (ECU), allowing it to make necessary adjustments and maintain the optimal fuel pressure for efficient combustion.

Functions Of The Fuel Pressure Sensor

The fuel pressure sensor performs several essential functions that contribute to the overall performance and efficiency of your vehicle:

- Monitoring Fuel Pressure: The fuel pressure sensor continually monitors the fuel pressure in the fuel rail or line. It provides real-time data to the ECU, allowing it to maintain a consistent pressure for optimal fuel delivery.

- Regulating Fuel Flow: By measuring the fuel pressure, the sensor helps regulate the fuel flow rate to ensure the engine receives the correct amount of fuel. This enables efficient combustion and enhances the overall performance of your vehicle.

- Detecting Fuel System Issues: The fuel pressure sensor is also responsible for detecting any potential issues within the fuel system. It alerts the ECU in case of abnormal fuel pressure readings, indicating problems like a clogged fuel filter or a failing fuel pump.

Signs Of A Faulty Fuel Pressure Sensor

Identifying signs of a faulty fuel pressure sensor is crucial to prevent any potential engine problems. Here are some common indicators that your fuel pressure sensor may be malfunctioning:

- Inconsistent Fuel Pressure Readings: If you notice fluctuating fuel pressure readings on your vehicle’s gauge or dashboard, it may indicate a faulty sensor.

- Poor Engine Performance: A faulty fuel pressure sensor can cause engine misfires, reduced power, hesitation, and poor acceleration.

- Hard Starting or Stalling: If your engine has trouble starting or stalls frequently, it could be a result of a faulty fuel pressure sensor affecting the fuel delivery system.

- Increased Fuel Consumption: A malfunctioning fuel pressure sensor can disrupt the fuel-air mixture, leading to increased fuel consumption.

- Check Engine Light: The illuminated check engine light can be an indicator of various engine-related issues, including a faulty fuel pressure sensor.

Credit: www.thedrive.com

Diagnosing Fuel Pressure Sensor Issues

When it comes to your vehicle’s overall performance, the fuel pressure sensor plays a crucial role. It measures the pressure of the fuel in the system and sends this information to the engine control unit (ECU) for optimal fuel delivery. However, like any other component, fuel pressure sensors can experience issues over time.

Using Obd-ii Scanner

If you suspect a problem with your fuel pressure sensor, using an OBD-II scanner can provide valuable insights. This diagnostic tool connects to the vehicle’s OBD-II port and retrieves error codes stored in the ECU. These codes can indicate specific issues related to the fuel pressure sensor, such as low voltage, erratic readings, or complete failure.

Here’s how you can use an OBD-II scanner to diagnose fuel pressure sensor issues:

- Plug the OBD-II scanner into the vehicle’s OBD-II port, usually located beneath the dashboard.

- Turn on the ignition and allow the device to establish a connection with the vehicle’s ECU.

- Select the “Read Codes” or similar option on the scanner’s menu.

- Review the retrieved codes and refer to the scanner’s user manual or online resources for their meanings.

- If any codes indicate fuel pressure sensor problems, it is recommended to proceed with further manual testing.

Performing Manual Tests

While an OBD-II scanner provides valuable information, performing manual tests can offer a more comprehensive understanding of fuel pressure sensor issues. These tests allow you to physically inspect the sensor, its connections, and check for any signs of malfunction or damage.

Here are some manual tests to diagnose fuel pressure sensor issues:

- Visual Inspection: Examine the sensor for physical damage, loose connections, or signs of leakage.

- Resistance Test: Use a multimeter to measure the resistance across the sensor terminals and compare it with the manufacturer’s specifications.

- Pressure Test: Connect a fuel pressure gauge to the fuel rail and crank the engine to observe the pressure readings. Abnormal readings may indicate a faulty sensor.

- Signal Test: With the engine running, monitor the output signal of the fuel pressure sensor using a voltmeter or oscilloscope. Any erratic or inconsistent readings could signify sensor issues.

By utilizing both an OBD-II scanner and performing manual tests, you can diagnose and identify fuel pressure sensor issues accurately. Remember to consult your vehicle’s repair manual or seek professional assistance if you encounter any difficulties during the diagnostic process.

Preparation For Replacement

Learn the step-by-step process for replacing your fuel pressure sensor with this comprehensive guide. Proper preparation before starting the replacement ensures a smooth and successful installation. Follow the detailed instructions to complete the replacement accurately and efficiently.

Gathering Necessary Tools

Before embarking on replacing your fuel pressure sensor, ensure you have the following tools handy:

- Socket set

- Screwdriver set

- Plastic gloves

- Safety goggles

- Shop rags

Choosing The Right Replacement Sensor

Selecting the correct replacement sensor is crucial for a successful fuel pressure sensor replacement. Prioritize:

- Matching OEM specifications

- Compatibility with your vehicle’s make and model

- Quality and reliability

Step-by-step Replacement Guide

In this step-by-step replacement guide, we will walk you through the process of replacing the fuel pressure sensor in your vehicle. The fuel pressure sensor plays a critical role in ensuring optimal engine performance, so it’s important to replace it when needed. Follow these instructions carefully to complete the replacement process successfully.

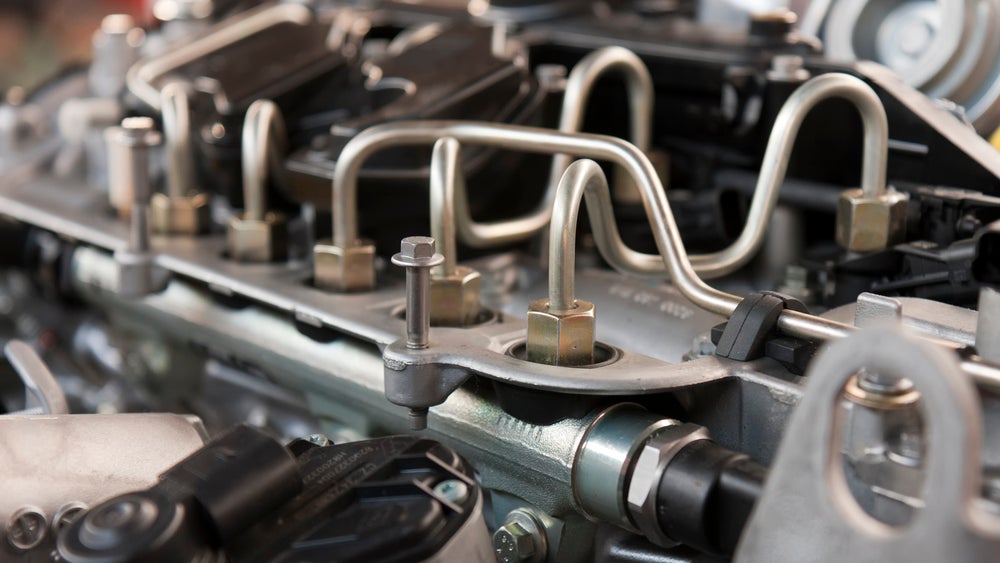

Locating The Fuel Pressure Sensor

Before starting the replacement process, you need to locate the fuel pressure sensor in your vehicle. The sensor is typically located on or near the fuel rail, which is the pipe that delivers fuel to the engine. Refer to your vehicle’s service manual or consult with a professional if you’re unsure about the exact location.

Removing The Old Sensor

Once you’ve located the sensor, the next step is to remove the old fuel pressure sensor. Start by disconnecting the electrical connector attached to the sensor. Then, use the appropriate tools to carefully remove the sensor from its mounting location. Be sure to follow safety precautions and release any built-up fuel pressure before removing the sensor.

Installing The New Sensor

After removing the old sensor, it’s time to install the new fuel pressure sensor. Begin by carefully positioning the new sensor in the mounting location and securing it in place. Then, reconnect the electrical connector to the sensor. Double-check that everything is properly secured before proceeding.

Testing And Calibration

This ultimate fuel pressure sensor replacement guide provides comprehensive information on testing and calibration methods, ensuring accurate and efficient sensor functionality.

Testing and calibration are crucial steps in the ultimate fuel pressure sensor replacement process. These steps ensure that the new sensor is accurately measuring fuel pressure, leading to optimal engine performance. Before installation, it’s important to check for leaks and then calibrate the new sensor for accurate readings.Checking For Leaks

Before installing the new fuel pressure sensor, thoroughly inspect the fuel lines, connections, and the sensor itself for any signs of leaks or damage. Use a flashlight and mirror if necessary to ensure a comprehensive check. Address any leaks or issues before proceeding with the replacement to prevent fuel system malfunctions or safety hazards.Calibrating The New Sensor

After installing the new fuel pressure sensor, it’s essential to calibrate it for accurate readings. Follow the manufacturer’s instructions for calibration procedures, as they can vary depending on the sensor model. Ensure the engine is off and the key is in the accessory position before initiating the calibration process. Use a reliable calibration tool or system to adjust the sensor to the correct fuel pressure levels, ensuring precise and reliable performance. During calibration, ensure that the sensor is securely connected and that there are no obstructions or disturbances that could affect the accuracy of the calibration process. Once calibrated, conduct a final check to verify the sensor’s readings against a known, accurate source to ensure proper functionality.

Credit: www.duramaxforum.com

Credit: www.ebay.com

Frequently Asked Questions On Ultimate Fuel Pressure Sensor Replacement Guide

What Is The Symptoms Of A Bad Fuel Pressure Sensor?

Symptoms of a bad fuel pressure sensor include poor acceleration, decreased fuel efficiency, engine stalling, and difficulty starting.

Will A Bad Fuel Pressure Sensor Throw A Code?

Yes, a bad fuel pressure sensor can trigger a diagnostic trouble code (DTC) in the vehicle’s system.

Will A Fuel Tank Pressure Sensor Throw A Code?

Yes, a faulty fuel tank pressure sensor can trigger a diagnostic trouble code to be displayed.

How Do You Replace A Fuel Rail Pressure Sensor?

To replace a fuel rail pressure sensor, first, locate the sensor on the engine. Then, disconnect the electrical connector and remove the sensor using an appropriate tool. Install the new sensor, reconnect the electrical connector, and ensure it’s properly secured.

Finally, test the sensor for functionality.

Conclusion

For a smooth fuel pressure sensor replacement, follow these steps carefully. Keeping your vehicle running smoothly is crucial. A well-maintained fuel pressure sensor ensures optimal performance. Don’t delay in addressing any sensor issues to prevent further damage. Trust this ultimate guide for a hassle-free replacement process.