Ls Oil Pan Torque Sequence

To torque LS oil pan: 74 in-lbs, sequence: 4, 2, 5, 6, 3, 1. This helps prevent leaks.

Ensuring the appropriate torque sequence for tightening the oil pan on your LS engine is crucial for maintaining a secure seal and preventing leaks. By following the sequence – 4, 2, 5, 6, 3, 1 – and torquing to 74 in-lbs, you can effectively secure the oil pan and maintain its integrity.

This simple step can save you from potential oil leaks and engine damage, ensuring optimal performance and longevity for your LS engine. Proper torque sequence is key to maintaining a tight seal and avoiding any future issues with your oil pan.

Credit: www.supermotors.net

Importance Of Ls Oil Pan Torque Sequence

The LS oil pan torque sequence is crucial in ensuring a proper seal and preventing oil leaks. Following the correct torque sequence helps to evenly distribute the pressure, ensuring a secure fit and preventing damage to the oil pan and engine components.

It is an essential step in maintaining the integrity of the engine’s lubrication system.

Properly torquing the LS oil pan is crucial to prevent oil leaks and ensure proper sealing. This seemingly small step plays a big role in keeping your engine running smoothly and avoiding potential complications down the road. Implementing the LS oil pan torque sequence technique not only safeguards against leaks but also extends the lifespan of your engine. In this section, we will delve into the importance of preventing oil leaks and ensuring proper sealing when following the LS oil pan torque sequence.

Preventing Oil Leaks

Oil leaks can have detrimental effects on your engine’s performance and longevity. Neglecting the LS oil pan torque sequence can lead to uneven pressure distribution and insufficient sealing, resulting in oil seeping out from the gaps. These leaks not only create a mess but also compromise the lubrication system, which is essential for reducing friction and ensuring proper engine function. By diligently adhering to the LS oil pan torque sequence, you create a tight seal, preventing oil leaks and maintaining the optimal oil level necessary for engine operation.

Ensuring Proper Sealing

Proper sealing is of utmost importance when it comes to the LS oil pan. The LS oil pan torque sequence enables secure attachment of the oil pan to the engine block, ensuring an airtight seal. A properly sealed oil pan prevents contaminants such as dirt, debris, and moisture from entering the oil system, thereby safeguarding the engine’s internal components from potential damage. Additionally, adequate sealing helps maintain consistent oil pressure, which contributes to optimal engine performance and efficiency.

To ensure a proper seal, it is essential to follow the LS oil pan torque sequence diligently. This sequence involves tightening the oil pan bolts gradually in a specific order, typically starting from the center and working your way outwards. This sequential tightening ensures even pressure distribution, minimizing the risk of leaks caused by uneven torque. Implementing this technique not only prevents oil leaks but also reduces the likelihood of pan warping, which can occur when excessive force is applied to individual bolts.

Credit: honda-tech.com

Steps To Follow

The LS oil pan torque sequence involves following a specific tightening pattern to ensure accurate installation and prevent leaks. Properly tightening the bolts in the correct order is crucial for the pan to securely seal and maintain optimal engine function.

Cleaning The Oil Pan And Engine Block Surfaces

Begin by removing the old gasket and cleaning both surfaces thoroughly with a degreaser.

Ensure there are no remnants of the old gasket or debris left behind on the oil pan and engine block.

Applying Proper Sealant

Apply a thin, even layer of high-quality gasket sealant around the oil pan flange for optimal adhesion.

Make sure to allow the sealant to set for the recommended time before proceeding to the next step.

Tightening The Bolts In The Correct Order

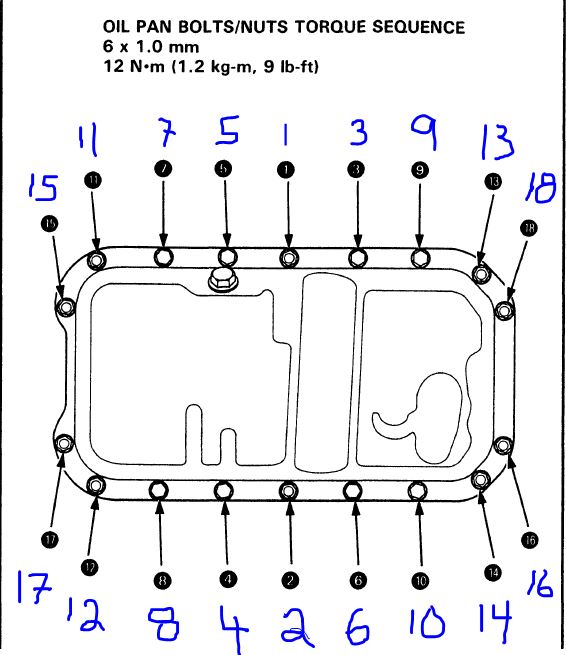

Use a torque wrench to tighten the bolts following the specified torque sequence provided by the manufacturer.

Start from the center and work your way outwards, evenly distributing the torque to prevent leaks.

Common Mistakes To Avoid

In the process of tightening the Ls oil pan bolts, it’s crucial to be aware of common mistakes to avoid. By understanding and steering clear of these blunders, you can ensure the optimal performance and longevity of your engine.

Over-tightening The Bolts

Avoid over-tightening the bolts on your Ls oil pan, as this can lead to damaged threads and potential leaks. Follow the manufacturer’s recommended torque specifications diligently to prevent this issue.

Skipping The Torque Sequence

Skipping the torque sequence when tightening the bolts may result in an uneven distribution of pressure, causing leaks and gasket failure. Make sure to follow the correct sequence specified in the manual.

Importance Of Using A Torque Wrench

Using a torque wrench is crucial when it comes to performing the LS oil pan torque sequence. This simple yet powerful tool is designed to tighten fasteners accurately, ensuring uniformity and preventing any potential damage to the oil pan of your engine.

Ensuring Uniform Tightening

One of the main reasons why using a torque wrench is essential is that it helps ensure uniform tightening of the oil pan fasteners. When you have multiple bolts or screws securing the oil pan, it is crucial to have consistent pressure applied to each one. Failure to do so can lead to uneven stress distribution, which may result in leaks, reduced performance, or even catastrophic failure over time.

A torque wrench provides the necessary precision to tighten each fastener to the manufacturer’s specified torque value. By following the torque sequence, which typically involves tightening bolts in a specific pattern, you can ensure that the force applied to each fastener is equal. This approach guarantees that the oil pan is held securely in place without any unnecessary stress that could lead to potential issues down the line.

Preventing Damage To The Oil Pan

Another crucial aspect of using a torque wrench for the LS oil pan torque sequence is the prevention of damage to the oil pan itself. The oil pan is a vital component responsible for storing and circulating oil throughout the engine, and any damage to it can lead to significant problems.

When tightening the oil pan fasteners, it’s important not to over-tighten them, as this can result in stripping the threads or even cracking the oil pan. On the other hand, under-tightening can cause the oil pan to become loose, leading to leaks and potential engine damage.

By using a torque wrench, you can accurately apply the specified torque value to each fastener, ensuring they are tightened to the correct tension without risking damage to the oil pan. This precise approach will help maintain the integrity of the oil pan and contribute to the overall longevity and reliability of your engine.

In conclusion, using a torque wrench for the LS oil pan torque sequence is not only important for ensuring uniform tightening but also for preventing damage to the oil pan itself. By following the manufacturer’s torque specifications and utilizing a torque wrench, you can perform this critical maintenance task with confidence, knowing that you are safeguarding your engine’s performance and longevity.

Final Checks

After completing the Ls oil pan torque sequence, it’s time for the final checks to ensure everything is in place for a smooth operation. These final checks are crucial to verify the torque specifications and to inspect for any potential leaks post-installation. Let’s dive into the critical steps for the final checks.

Verifying Torque Specifications

Verify that all the bolts have been torqued to the manufacturer’s specifications using a torque wrench. Ensure that each bolt has the correct amount of torque to prevent any potential loosening over time. Refer to the specific torque values provided by the manufacturer for each bolt to avoid under or over-tightening.

Looking For Leaks After Installation

Once the torque specifications are verified, it is important to inspect the oil pan and surrounding areas for any signs of leaks. Check the gasket and sealant for any visible leaks or seepage. Additionally, observe the lower portion of the engine for any oil accumulation, which could indicate a leak from the oil pan. It’s crucial to address any leaks promptly to prevent potential damage to the engine.

Credit: www.autozone.com

Frequently Asked Questions For Ls Oil Pan Torque Sequence

What Is The Proper Torque For Oil Pan Bolts?

The proper torque for oil pan bolts is typically around 10-15 ft-lbs, but it’s best to consult your vehicle’s specific torque specifications for accuracy.

What Is The Pattern For Tightening An Oil Pan?

To tighten an oil pan, start in the center and work your way outwards in a crisscross pattern for even pressure distribution. Use a torque wrench to achieve the proper tightness specified in your vehicle’s manual.

What Is The Torque On The Oil Pan Bolts On A 6.0 Ls?

The recommended torque for the oil pan bolts on a 6. 0 LS is 18 ft-lbs.

What Is The Torque On Ls Valley Pan Bolts?

The torque on LS Valley pan bolts is typically set to around 18 lb-ft. This is the recommended amount for securing the pan in place.

What Is The Torque Sequence For Ls Oil Pan?

To ensure proper sealing and prevent leaks, the torque sequence for LS oil pan typically follows a crisscross pattern.

Why Is The Torque Sequence Important For The Oil Pan?

The torque sequence is crucial to evenly distribute pressure, creating a proper seal and preventing warping or damage to the oil pan and engine components.

How Does The Torque Sequence Affect Oil Pan Installation?

Following the torque sequence ensures uniform clamping force, minimizing the risk of leaks and maintaining the integrity of the gasket or sealing material.

Conclusion

It is crucial to follow the correct torque sequence when tightening the oil pan on your LS engine. Failing to do so can lead to oil leaks and potential engine damage. By adhering to the proper sequence, you ensure an even distribution of torque, preventing any issues down the line.

Remember to consult your vehicle’s manual for the specific torque values and sequence to follow. Properly torquing your LS oil pan is an essential step in maintaining the longevity and performance of your engine.