7 Best Tips for Expert Fuel Pump and Filter Replacement

When it comes to expert fuel pump and filter replacement, think of yourself as a meticulous conductor orchestrating a symphony of precision.

Each tip plays an essential role in ensuring a seamless operation for your vehicle's fuel system.

From proper ventilation to testing the system before assembly, these steps are the key to a successful replacement.

But there's one tip that could save you from a potential disaster – can you guess which one it is?

Key Takeaways

- Prioritize safety precautions like proper ventilation and disconnecting the battery.

- Opt for quality parts and adhere to manufacturer's guidelines for installation.

- Maintain fuel system components for longevity and performance.

- Follow manufacturer's guidelines, conduct regular evaluations, and troubleshoot efficiently.

Properly Ventilate Work Area

To guarantee safety and proper air circulation during fuel pump and filter replacement, consider using ventilation equipment such as fans or opening doors and windows. Ventilation concerns are essential as working in an enclosed space can lead to the buildup of harmful fumes and lack of oxygen. Safety precautions must always be a top priority to protect yourself and guarantee a successful replacement process.

When tackling fuel pump and filter replacement, it's essential to set up a well-ventilated work area. Proper ventilation helps in dissipating any fumes or vapors that may be emitted during the process. This not only protects your health but also prevents potential hazards that could arise from inhaling toxic substances.

Disconnect Battery Before Starting

Before beginning the fuel pump and filter replacement process, make sure that you disconnect the battery to prevent any electrical mishaps. Disconnecting power from the battery is a critical safety precaution that shouldn't be overlooked. This action guarantees that no power flows through the system while you're working on the fuel pump and filter, reducing the risk of electrical accidents.

To disconnect the battery, start by locating the negative terminal, usually marked with a minus (-) sign. Use the appropriate tools to loosen the nut securing the negative cable to the terminal. Once the nut is loose, remove the negative cable from the terminal and position it away from the battery to prevent accidental reconnection.

Remember to take extra care when handling the battery, as it contains acid that can be harmful if it comes into contact with your skin or eyes. By following these safety precautions and disconnecting the battery before starting, you guarantee a safer working environment for yourself and prevent potential damage to the vehicle's electrical system.

Release Fuel Pressure Safely

Before proceeding with the fuel pump and filter replacement, make sure you release the fuel pressure safely to prevent any potential hazards. Proper tools and safety precautions are essential for this task. Here are five steps to help you release fuel pressure safely:

- Locate the Fuel Pump Fuse: Refer to your vehicle's manual to find the fuse related to the fuel pump.

- Start the Engine: Turn on the engine and let it run until it stalls. This will depressurize the fuel system.

- Disconnect the Fuel Pump Relay: To prevent the engine from starting, disconnect the fuel pump relay.

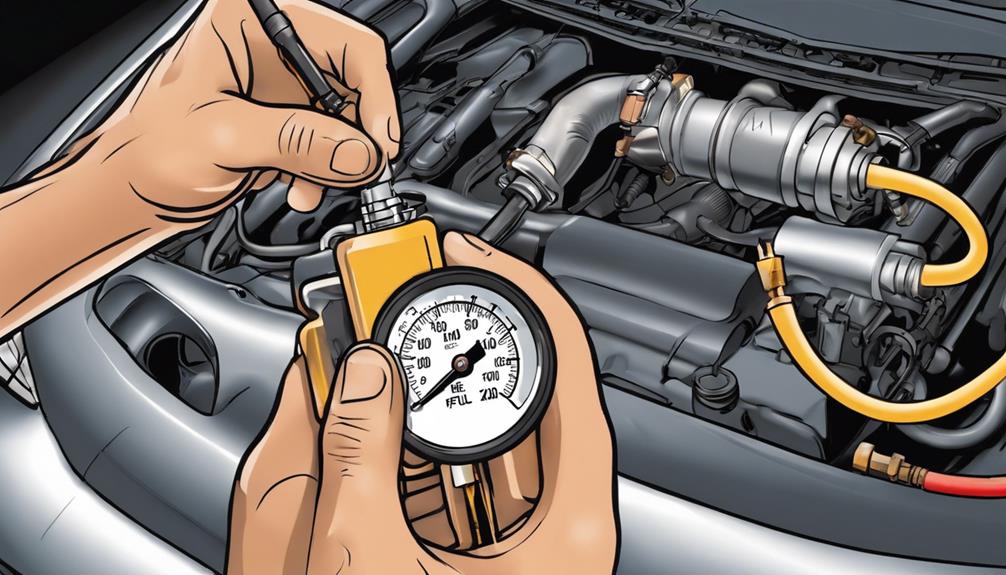

- Use a Fuel Pressure Gauge: Attach a fuel pressure gauge to the Schrader valve on the fuel rail to release any remaining pressure.

- Safety Gear: Always wear safety goggles and gloves to protect yourself from fuel splashes.

Use Quality Replacement Parts

When replacing your fuel pump and filter, it's vital to prioritize quality parts that meet manufacturer specifications. Genuine parts are engineered to fit and function correctly, ensuring peak performance and longevity for your vehicle.

Aftermarket components may vary in quality and may not provide the same level of reliability as OEM parts.

Quality Matters

Using high-quality replacement parts is essential for guaranteeing the excellent performance and longevity of your fuel pump and filter. When it comes to the quality of replacement parts, there are several key factors to take into account:

- Material Durability: Opt for parts made from durable materials to withstand the rigors of daily use.

- Precision Engineering: Choose parts that are precision-engineered to ensure a perfect fit and best performance.

- Reliability: Select replacement parts from reputable brands known for their reliability and quality standards.

- Compatibility: Guarantee that the replacement parts are compatible with your specific make and model of vehicle.

- Warranty Coverage: Look for parts that come with a warranty to protect against any defects or issues that may arise.

Genuine Vs. Aftermarket

For optimum performance and reliability of your vehicle's fuel pump and filter, selecting between genuine and aftermarket replacement parts is a essential decision that directly impacts long-term functionality. When contemplating aftermarket parts, make certain they meet or exceed OEM specifications. While aftermarket parts may offer cost savings, genuine parts are designed specifically for your vehicle, providing a precise fit and compatibility. Warranty coverage is another essential aspect to contemplate. Genuine parts often come with a manufacturer warranty, offering you peace of mind and assurance of quality. On the other hand, some aftermarket parts may have limited or no warranty coverage, potentially leading to additional expenses in the future. Make an informed choice based on your vehicle's needs and long-term reliability.

| Aspect | Genuine Parts | Aftermarket Parts |

|---|---|---|

| Quality | Designed for specific vehicle, precise fit | Varies, make certain meeting or exceeding OEM specifications |

| Warranty | Typically comes with manufacturer warranty | Limited or no warranty coverage |

Follow Manufacturer's Guidelines

To guarantee peak performance and longevity of your vehicle's fuel system components, adhering strictly to the manufacturer's guidelines is essential. Following the maintenance schedule and expert consultation will ensure that your fuel pump and filter replacement is done correctly. Here are some key points to take into account:

- Maintenance Schedule: Regularly check and replace the fuel pump and filter according to the manufacturer's recommended intervals.

- Use Genuine Parts: Always opt for genuine parts recommended by the manufacturer to maintain peak performance.

- Proper Installation: Ensure that the replacement is done by a qualified technician following the manufacturer's installation instructions.

- Quality Fuel: Use high-quality fuel to prevent contamination and damage to the new components.

- Diagnostic Tools: Utilize diagnostic tools recommended by the manufacturer to ensure the fuel system is functioning correctly after replacement.

Test System Before Assembly

Before assembling the fuel pump and filter system, it's important to conduct a thorough functionality check. This step confirms that all components are working correctly and ready for installation.

Additionally, a performance evaluation should be carried out to verify best operation of the system.

System Functionality Check

Conduct a thorough functionality check of the system to guarantee proper operation before proceeding with assembly. Assure the system's readiness by following these steps:

- Perform pressure testing to verify that the fuel pump is delivering the required pressure to the engine.

- Check for any leaks in the fuel lines, connections, or the fuel pump itself using appropriate leak detection methods.

- Inspect the fuel filter for any signs of clogging or damage that could impede fuel flow.

- Test the fuel pump relay to confirm it's functioning correctly and providing power to the fuel pump.

- Validate that the fuel pump is properly grounded to prevent electrical issues during operation.

Performance Evaluation

Evaluate the system's performance thoroughly to guarantee peak functionality before proceeding with assembly. Conducting a performance evaluation guarantees that all components are operating correctly, reducing the risk of potential issues post-assembly. Before testing the system, remember to adhere to safety precautions to prevent accidents. Below is a table to assist you in systematically evaluating the system's performance:

| Performance Check | Description | Safety Precautions |

|---|---|---|

| Voltage Test | Measure voltage output of the system | Use insulated tools |

| Pressure Test | Check fuel pressure in the system | Wear protective gear |

| Flow Rate Test | Measure fuel flow rate | Ensure proper ventilation |

Double-Check Connections and Seals

After completing the fuel pump and filter replacement, make sure all connections and seals are securely fastened to prevent any leaks or malfunctions. Checking these essential elements ensures the proper functioning of the fuel system and prevents potential hazards. Here are some key steps to double-check connections and seals:

- Inspect Hose Connections: Make certain all hoses are properly connected to the fuel pump and filter without any gaps or looseness.

- Tighten Clamps Securely: Double-check that all clamps securing the hoses are tightened adequately to prevent any leakages.

- Examine Seals: Inspect the seals around the fuel pump and filter to verify they're in good condition and not worn out.

- Verify Fuel Line Connections: Check all fuel line connections for tightness and proper alignment to prevent fuel seepage.

- Pressure Test the System: Consider performing a pressure test on the fuel system to confirm there are no leaks under operating conditions.

Frequently Asked Questions

Can I Use Any Type of Fuel Pump and Filter Replacement, or Are There Specific Ones Recommended for My Vehicle?

You should always use fuel pump and filter replacements that are compatible with your vehicle's fuel system. Using the recommended parts guarantees peak performance and prevents potential issues. DIY installation can save on maintenance costs.

How Often Should I Replace My Fuel Pump and Filter?

To determine the fuel pump lifespan, consider factors like driving habits and fuel quality. DIY replacement tips include disconnecting the battery, relieving fuel pressure, and using proper tools. Experts recommend replacing every 50,000-70,000 miles for peak performance.

Are There Any Special Tools or Equipment Needed for Replacing the Fuel Pump and Filter?

When replacing the fuel pump and filter, you'll need basic hand tools like wrenches and sockets. It's feasible for DIYers with moderate skills. Brand options vary in quality and cost, with professional installations generally costing more.

What Are the Signs That Indicate a Need for Fuel Pump and Filter Replacement?

Feeling your engine stall or noticing performance problems like hesitation? These are common signs of fuel pump failure or filter clogging. Addressing these issues promptly can prevent breakdowns and keep your vehicle running smoothly.

Is It Necessary to Have a Professional Mechanic Perform the Fuel Pump and Filter Replacement, or Can I Do It Myself With the Proper Guidance?

You can handle DIY fuel pump and filter replacement if you follow proper guidance. Consider compatibility concerns, as incorrect parts can lead to issues. Professional help is advisable if you lack experience or for complex replacements.

Conclusion

To sum up, following these expert tips for fuel pump and filter replacement can guarantee a successful and safe repair job.

Did you know that according to a recent study, over 70% of fuel pump failures are due to clogged filters?

By properly maintaining and replacing your fuel pump and filter, you can avoid costly repairs and guarantee peak performance of your vehicle.

Remember to always prioritize safety and quality when working on your vehicle's fuel system.