Why Do Wheel Bearings Fail?

Ever wondered why wheel bearings fail at the most inconvenient times?

The reasons behind this common issue might surprise you.

From the impact of deep water to the strain caused by unbalanced tires, various factors can contribute to the premature wear and tear of these important components.

Understanding these causes could potentially save you from unexpected breakdowns and costly repairs.

Key Takeaways

- Deep water exposure washes away lubricants, leading to friction damage and premature wear.

- Mechanical stress from poor road conditions accelerates wear and misalignment.

- Weight-related strain with heavy loads hastens deterioration and heat generation.

- Installation errors, like inadequate torque values, cause misalignment and increased friction.

Deep Water Exposure

Deep water exposure poses a significant risk to wheel bearings by washing away essential lubricants, leading to reduced lubrication within the bearing system. When a vehicle traverses deep waters, water infiltration into the wheel bearing system becomes a concern, as this can elevate friction levels and subsequently result in overheating.

The consequences of excess water exposure are dire, as it can cause friction damage to the wheel bearings. This damage can compromise the overall performance of the bearings, manifesting in various friction-related issues that can ultimately lead to premature wear and potential failure of the system.

It's imperative to be cautious when driving through deep water to avoid subjecting the wheel bearings to conditions that may result in decreased lubrication, increased friction, and the associated risks of damage and failure.

Poor Road Conditions

Traversing through rugged road conditions can subject wheel bearings to excessive stress, potentially leading to misalignment and accelerated wear. Important road conditions, such as potholes and rough terrain, can exert increased pressure on wheel bearings, causing them to experience excessive vibrations and impacts. This continuous stress can compromise the integrity of the bearings, making them more susceptible to premature failure.

Driving on bumpy roads not only accelerates wear on wheel bearings but also exposes them to debris and contaminants present on poorly maintained surfaces. These foreign particles can infiltrate the bearing system, causing damage and reducing the overall lifespan of the bearings. Additionally, the constant exposure to uneven road surfaces can contribute to misalignment issues, further exacerbating the strain on the wheel bearings.

It is important to be mindful of the road conditions you traverse to minimize the risk of premature wheel bearing failure due to the stresses induced by poor road conditions.

Unbalanced Tires

Unbalanced tires pose a significant risk to wheel bearings, causing uneven strain that can lead to premature wear and failure. When tires are unbalanced, they create vibrations that transmit to the wheel bearings, disrupting their smooth rotation.

This constant vibration results in increased strain on the bearings, accelerating the degradation of their components. The imbalance from unbalanced tires also increases friction on the wheel bearings, diminishing their efficiency and shortening their lifespan.

To prevent these issues, regular tire balancing is important. By ensuring that your tires are properly balanced, you can safeguard your wheel bearings from unnecessary strain and potential failure.

Overweight Loads

Carrying overweight loads greatly strains wheel bearings, hastening wear and increasing the risk of failure. When vehicles are overloaded, the excessive weight places undue stress on the wheel bearings, leading to premature wear and potential structural damage. Sharp braking maneuvers and rough driving conditions further compound the strain, accelerating the deterioration process. The additional weight not only stresses the bearings but also generates heat, causing lubrication breakdown and increased friction, both of which are detrimental to the bearings' longevity. Ensuring vital weight distribution is essential to prevent overloading, as uneven weight distribution can compromise the structural integrity of the bearings, heightening the risk of seal damage and contamination. By maintaining appropriate weight limits and distribution, you can safeguard your wheel bearings from the detrimental effects of overloading, preserving their functionality and extending their lifespan.

| Effects of Overweight Loads on Wheel Bearings | |

|---|---|

| Excessive Strain | Premature Wear |

| Heat Generation | Lubrication Breakdown |

| Structural Integrity | Weight Distribution |

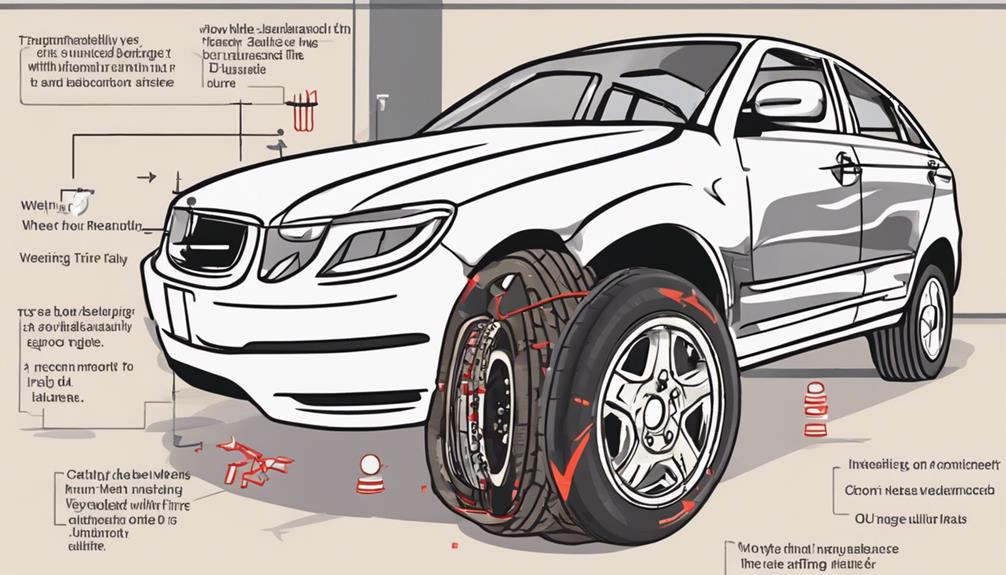

Improper Installation

Improper installation of wheel bearings, characterized by the use of incorrect tools or techniques, can greatly contribute to premature bearing failure. When inadequate torque values are applied during installation, the bearing may not seat properly, leading to performance issues.

Failure to adhere to manufacturer specifications for installation can result in misalignment and premature wear on the wheel bearings, causing increased friction, heat buildup, and potential damage to surrounding components.

To avoid such issues, it's important to follow correct installation procedures outlined by the manufacturer and carried out by qualified professionals. By ensuring that the wheel bearings are installed correctly, you can enhance their longevity and optimize their performance, ultimately preventing premature failure.

Frequently Asked Questions

What Causes Wheel Bearings to Go Bad?

When wheel bearings fail, it's often due to factors like lubrication issues, overloading stress, corrosion damage, high temperatures, improper installation, contaminant ingress, material fatigue, axle misalignment, and road vibrations. These issues can lead to breakdowns.

How Long Should Wheel Bearings Last?

Your wheel bearings should last around 136,000 to 160,000 kilometers. Regular maintenance, quality materials, and safe driving habits play key roles in their longevity. Timely checks, replacement if needed, and expert guidance guarantee safety.

How Likely Is a Wheel Bearing to Fail?

Wheel bearings are prone to fail due to various factors like driving habits, road conditions, and mileage. Signs of failure include unusual noise or vibration. Prevent issues with regular maintenance, inspections, and avoiding stress factors like overloading.

What Is the Main Cause of Bearing Failure?

Improper lubrication due to water contamination is a major cause of wheel bearing failure. Overloading your vehicle, rough handling, and poor maintenance practices exacerbate the issue. Guarantee proper sealing and installation to prevent premature wear.

Conclusion

To summarize, the failure of wheel bearings is a critical issue that can lead to catastrophic consequences if not addressed promptly.

From deep water exposure to improper installation, the reasons for wheel bearing failure are numerous and potentially dangerous.

Neglecting these warning signs can result in costly repairs and even jeopardize your safety on the road.

Stay vigilant, address issues promptly, and keep your bearings in top condition to make sure a smooth and safe driving experience.