Breaker Bar vs Impact Wrench| 2 Best Acme Tools Special

But just what are these two pieces of equipment? Breaker Bar vs Impact Wrench?How do they measure out? How To Set The Torque Wrench? Or What are the areas of their applications? And just what are some of their downsides? We can never offer straight answers to these questions. That is why we dedicate the entire scope of this article to answer them.

When making joints along the disparate parts and constituent components of the items you work on, you need to employ and subsequently make do with the relevant pieces of equipment. Two of these stand out. These are the breaker bar and the impact wrenches respectively.

A. What is Breaker bar?

Also called a power bar, a breaker bar is a long and non-ratcheting bar that is used to break loose the tight or rusted fasteners. They enable the attainment of this end primarily given their super tough nature and the ability to greatly amplify the forces you apply to them.

Applications

A typical breaker bar comprises a long steel bar on whose head is attached a socket drive. This head rotates to a maximum angle of about 240° to empower the user to place it in an optimal position for the sake of generating the necessary leverage needed to work a difficult bolt or nut.

- Rotates and swivels for maximum impacts

- Powerful enough to take on the rusted and hard nuts

- Amplifies the input force by a considerable margin

- Greatly minimizes any possible injuries or hazards during use

- Its handle is long enough to negate the need to be close to the item

- Calls for extreme muscle power to handle owing to its manual character

B. What is Impact Wrench?

An impact wrench is a tool that is used to fasten or loosen nuts and bolts. It is powered or pneumatic and thus calls for limited muscle power. The item finds relevance in power mechanics as it is simpler and less of a hassle to make use of. On the same note, it brings about better and more reliable outcomes.

Also Read: Pass Through Socket Set Buying Guide

Applications

It is widely used to loosen the lug nuts from the trucks and the trucks. Also, it comes in handy for those applications that take longer and require the prolonged input of the necessary muscle or operating power. The bonds it creates are generally longer lasting and tend to confer exceptional support to the load above it.

- Powered to negate the input for excess muscle power

- Able to endure the test of time due to the powerful stature

- Unlikely to cause fatigue or strains regardless of how long it is used

- Greatly relevant in power mechanics and areas of intense application

- Varies its torque output in line with the prevailing needs at the moment

- Comes at a greater cost of acquisition

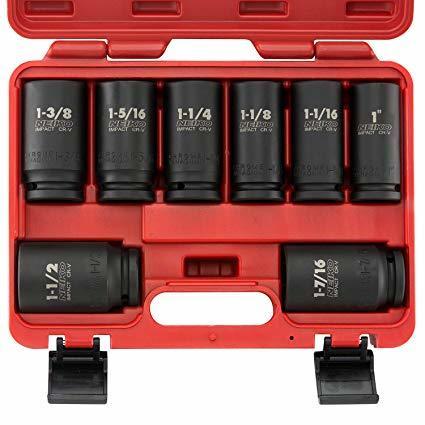

Also Read : Best Impact Sockets For The Money

Similarities Between the breaker bar vs impact wrench

They share the following similarities:

General use

These two pieces of equipment are used for tightening and loosening the nuts. They may differ inasmuch as the specific kinds of nuts they handle or in the exact ways they do so though. You hence have them for your consideration if you are a seasoned mechanic.

Modes of operations

They generally act to eliminate the clogs or tautness (when loosening the nuts) or providing the torque (when tightening the same). To achieve either, they accept the input of the impact from whichever source and translate the same to torque to attain the necessary ends.

Material makeup

Stainless steel is extensively used to make these twin pieces of equipment. This material is strong and powerful enough to endure the test of time. That it does not corrode also makes it appropriately reliable for long-term engagements. This stainless steel also endures many incidences of use and guarantees exceptional use.

Recommended Article : How To Set The Torque Wrench

Differences between the breaker bar and the impact wrench

Methodology of use

How you use these two apparatuses differ considerably. The breaker bar is largely manual and thus draws its power from the muscles of the users of the same. Its impact wrench on the other hand is pneumatic or powered by electrical means. As such, it is more automated.

Sheer size

A typical impact wrench is larger in size when compared to the breaker bar counterpart. This sheer massive size means it is overall likely to induce some clutter in your work area. Given the smaller size of the breaker bar, it is more suitable for on-the-go applications such as remote use.

Cost implications

You will generally have to part with lots of cash to purchase and operationalize an impact wrench as opposed to the breaker bar. This item, as has already been stated, has lots of extra features and also draws its power from the mains or pneumatic sources.

Precise applications

Even though they both serve to fasten and loosen the tight nuts and bolts, they differ slightly with regards to the specific kinds of tasks they do. The breaker bar is mainly used to tackle corroded fasteners while the impact wrench tackles live (un-corroded) and extremely tough fasteners.

Convenience of engagements

An impact wrench gives you the convenience of setting the force output in line with the precise torque requirements you may have to contend with at any given time. A breaker bar lacks the ability to vary the torque output. It leaves you to your devices with regard to this matter.

Conclusion

From the foregoing explanations, one thing stands out. That these two items, though largely intended to tackle more or less similar applications, are not perfect substitutes for each other. They differ slightly inasmuch as their precise applications are and the kinds of items they may generally handle.

It is not enough for you to merely know about these twin items. You definitely have to go beyond mere knowledge and purchase one for yourself. We recommend the breaker bar if you are a do-it-yourselfer and an impact wrench if you are a professional mechanic.